Anti-blocking and anti-explosion rubber oil conveying pipe

A rubber tube, anti-blocking technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve problems such as pipe blockage, pipe bursting, oil leakage pollution, etc., to improve positioning stability, prevent blockage and burst, and prevent pipelines the burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] see Figure 1-9 , the present invention provides a kind of technical scheme:

[0049] An anti-clogging and anti-riot rubber oil pipeline, comprising:

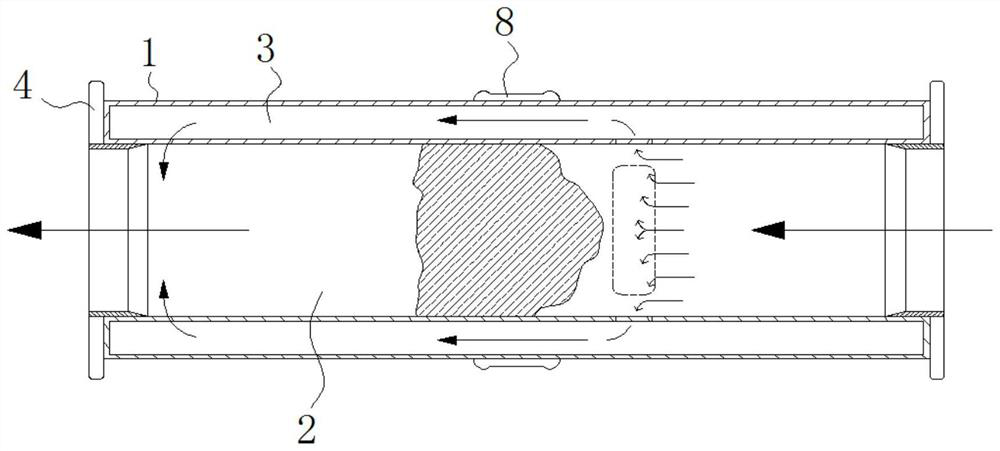

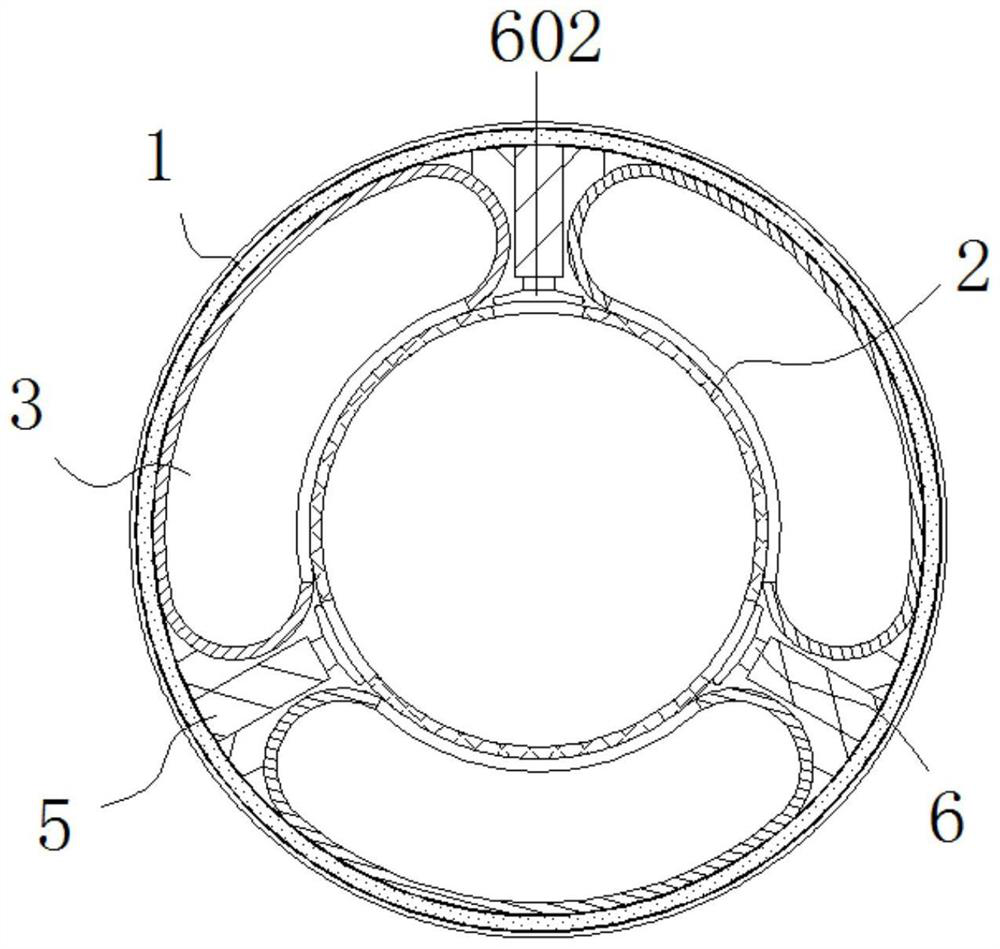

[0050] The outer tube 1 is provided with an inner lining rubber tube 2 coaxially inside, and a secondary tube 3 is fixedly installed at an equal angle between the outer tube 1 and the inner lining rubber tube 2, and the left and right sides of the outer tube 1 and the inner lining rubber tube 2 are fixed. A connector 4 is fixed at both ends;

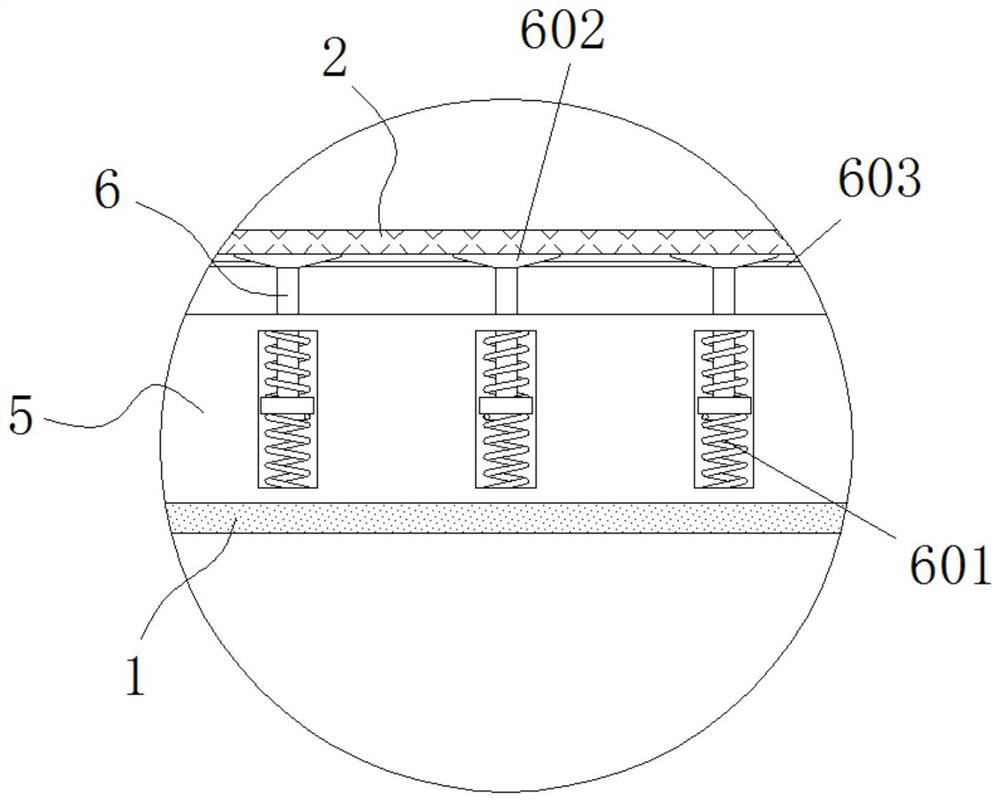

[0051] using as Figure 1-3 The technical solution shown also includes: a support plate 5, which is equiangularly distributed on the inner side wall of the outer tube 1, and the outer tube 1 is located between the adjacent secondary tubes 3, and the support plate 5 is movably installed through the There is a support rod 6, and the output end of the support rod 6 is connected to the outer side wall of the inner lining rubber tube 2, and the installed inner lining rubber tube 2 is...

Embodiment 2

[0057] see Figure 1-6 and Figure 10 , the present invention provides a kind of technical scheme:

[0058] An anti-clogging and anti-riot rubber oil pipeline includes an outer pipe 1, an inner lining rubber pipe 2 is arranged coaxially inside, and a secondary pipe 3 is fixedly installed at an equal angle between the outer pipe 1 and the inner lining rubber pipe 2, and the outer A connector 4 is fixed on the left and right ends of the tube 1 and the inner rubber tube 2;

[0059] using as Figure 1-3 The technical solution shown also includes: a support plate 5, which is equiangularly distributed on the inner side wall of the outer tube 1, and the outer tube 1 is located between the adjacent secondary tubes 3, and the support plate 5 is movably installed through the There is a support rod 6, and the output end of the support rod 6 is connected to the outer side wall of the inner lining rubber tube 2, and the installed inner lining rubber tube 2 is stably supported by the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com