Optical lens centrifugal cleaning machine

A centrifugal cleaning, optical lens technology, applied in the direction of cleaning flexible items, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of spray effect, direct particle effect, scratches, etc., to reduce the possibility of scratches The effect of high performance, high spray utilization rate, and sophisticated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

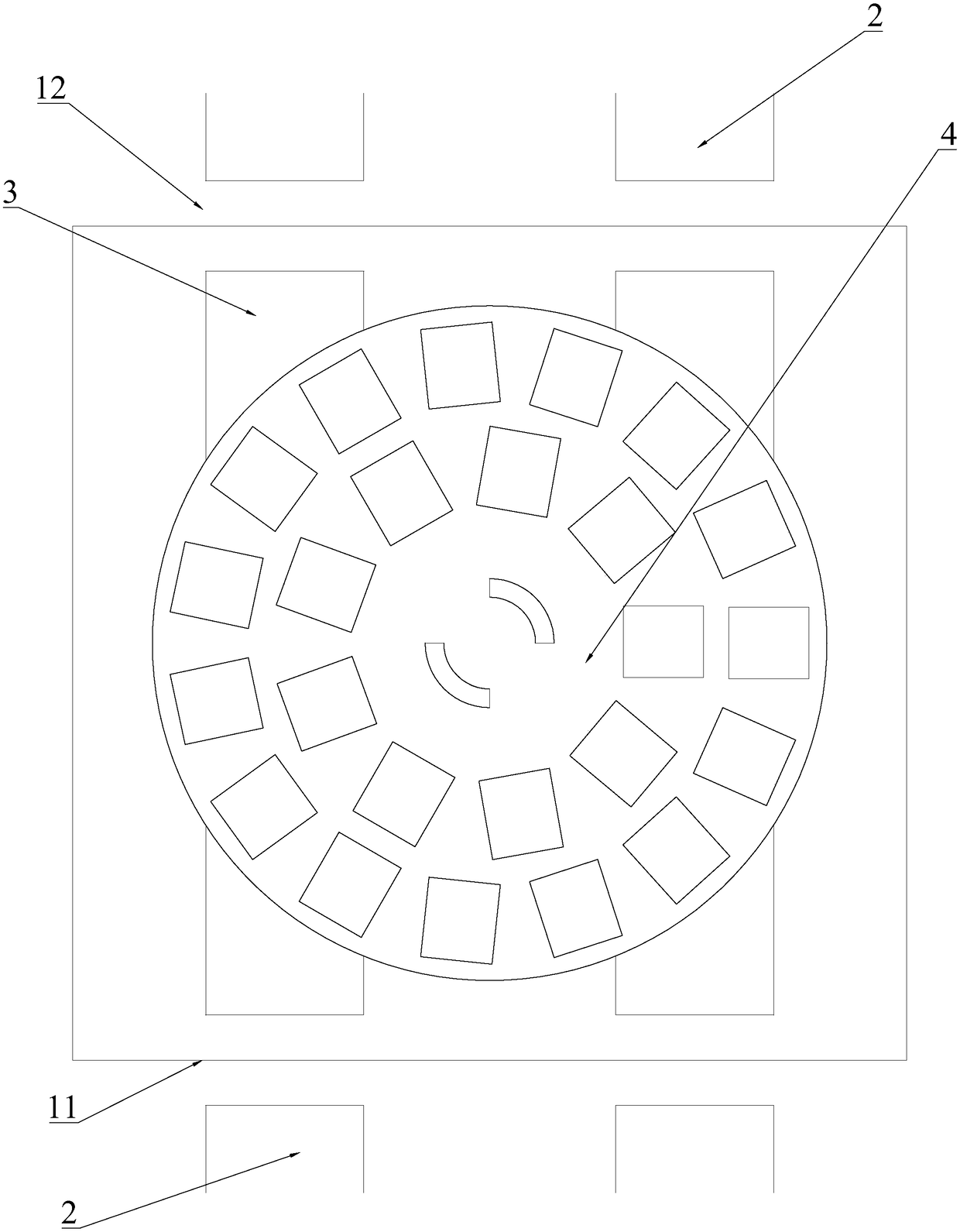

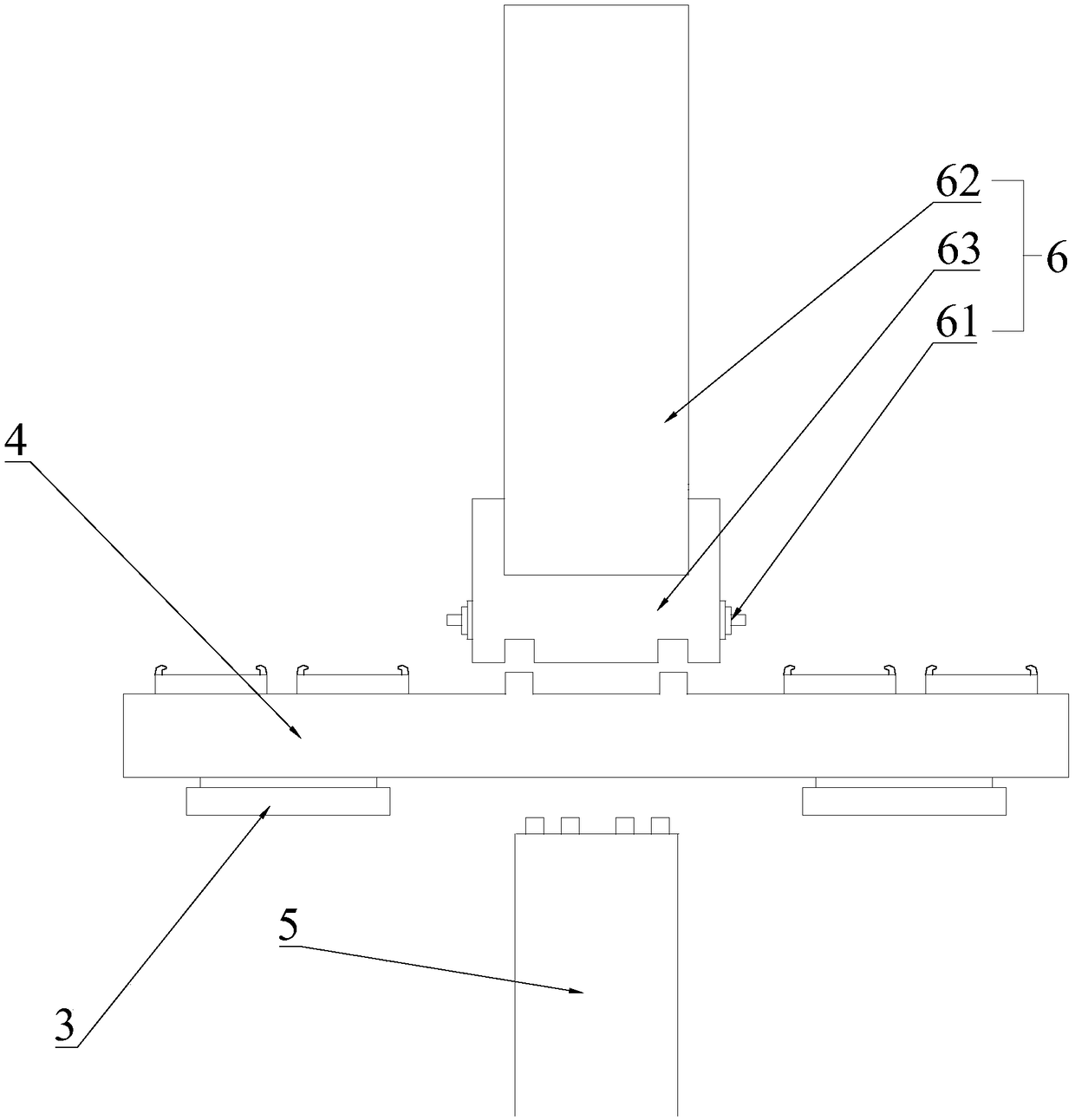

[0017] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the optical lens centrifugal cleaning machine of the present invention includes a housing 1, and the housing 1 is provided with an inlet 11 and an outlet 12, and the inlet 11 and the outlet 12 are provided with two conveying conveyors arranged in parallel. The track 2, the housing 1 is provided with an auxiliary track 3, and also includes a loading carousel 4 arranged in the housing 1, and also includes a rotating shaft 5 located on the lower side of the loading carousel 4, and also includes a The spray assembly 6 on the upper side, the rotating shaft 5 rises and falls in the axial direction, the rotating shaft 5 rises to separate the loading carousel 4 from the auxiliary track 3 and conflicts with the spraying assembly 6, after the rotating shaft 5 rises, the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com