Gorgon fruit shelling device for agricultural production

A Gorgon fruit and agricultural technology, which is applied in the field of Gorgon fruit shelling devices for agricultural production, can solve the problems of destroying the inner pulp and unable to squeeze the fruit out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

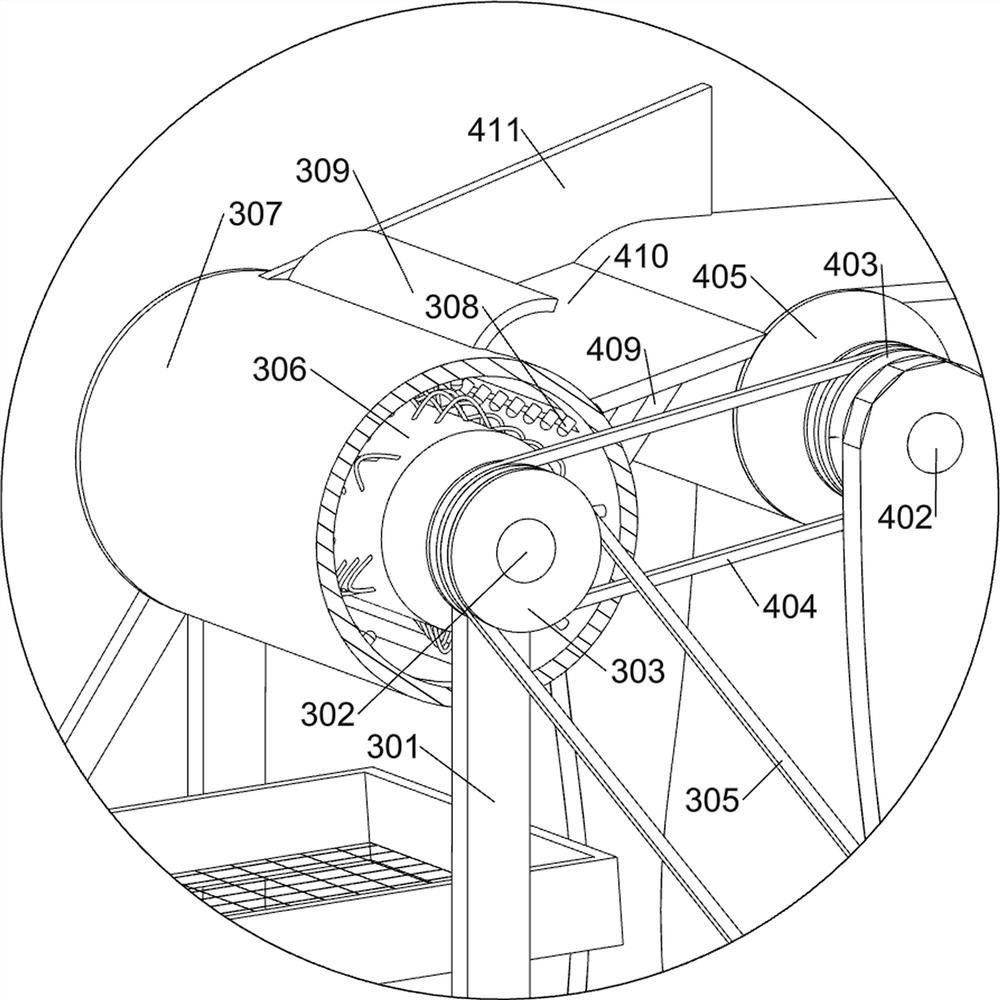

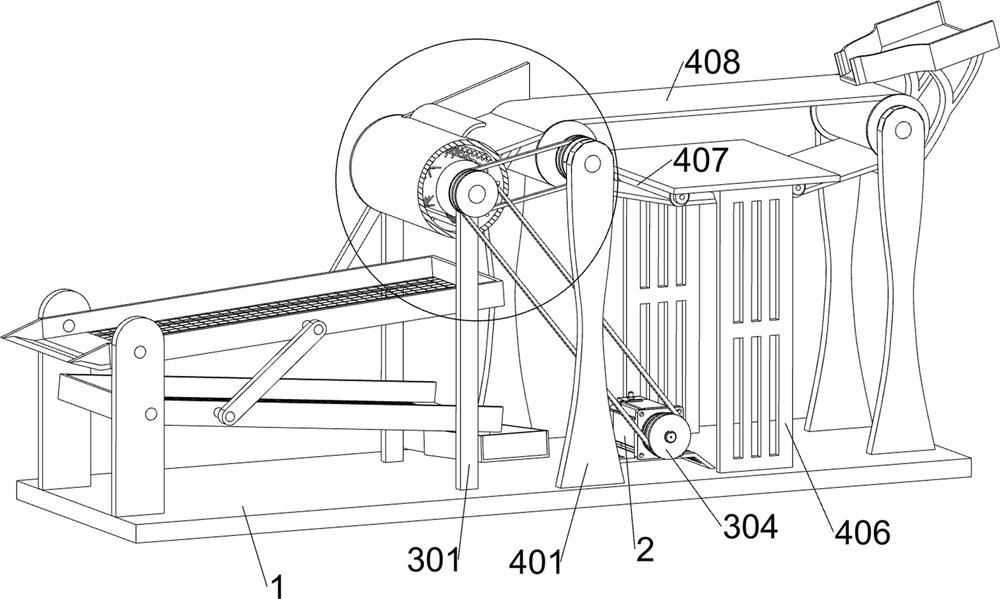

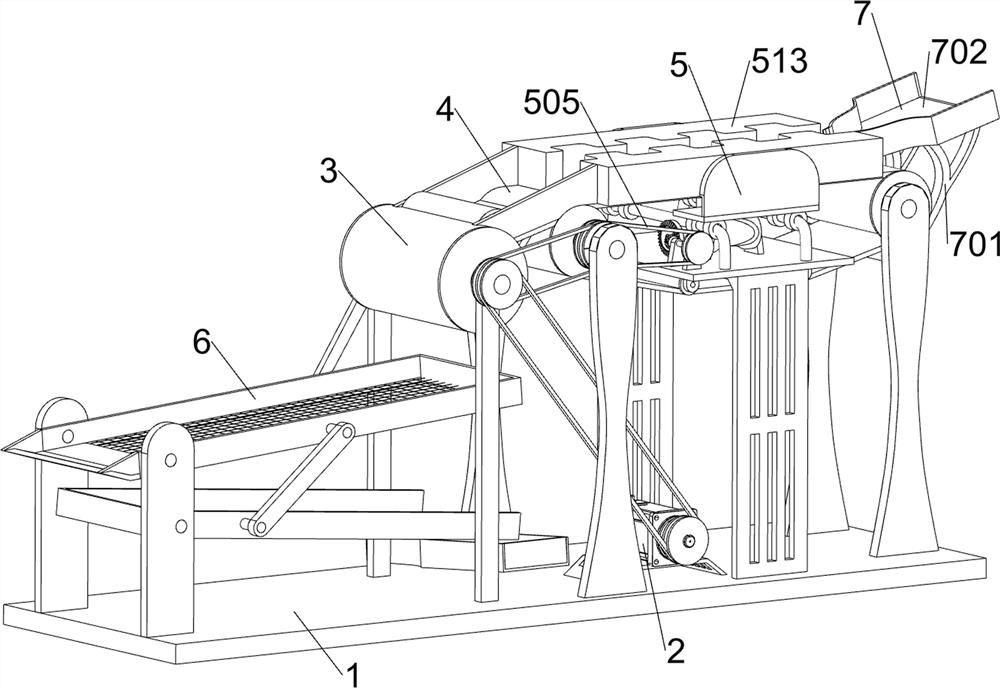

[0020]A gorgon peeling device for agricultural production, such asfigure 1 ,figure 2 ,image 3 ,Figure 4 withFigure 5As shown, it includes a bottom plate 1, a servo motor 2, a shedding component 3, a transmission component 4, and a pressing component 5. The top right side of the bottom plate 1 is provided with a servo motor 2, the top middle of the bottom plate 1 is provided with a falling component 3, and the top right of the bottom plate 1 A transmission assembly 4 is arranged on the side, and an extrusion assembly 5 is arranged on the upper part of the transmission assembly 4.

[0021]The worker puts the gorgon on the transmission assembly 4, and then starts the servo motor 2 to work. The servo motor 2 drives the transmission assembly 4 to work through the falling assembly 3, and the transmission assembly 4 drives the squeezing assembly 5 to squeeze the gorgon, and the finished gorgon is squeezed , The pulp and shell are transported by the transmission assembly 4 to the shedding asse...

Embodiment 2

[0029]On the basis of Example 1, such asfigure 1 withFigure 5As shown, it also includes a screening assembly 6, which is located at the top left side of the bottom plate 1. The screening assembly 6 includes a support plate 601, a first screen 602, a second screen 603, a crank 604, a second connecting rod 605, The third connecting rod 606 and the collecting frame 607, the top left side of the bottom plate 1 is provided with a support plate 601 symmetrically in the front and rear, and a second screen plate 603 is rotatably provided between the middle of the front and rear support plates 601. The right side of the second screen plate 603 is connected to The lower side of the support rod 301 is connected in a sliding manner. The right end of the second sieve plate 603 is provided with a receiving opening. A first sieve plate 602 is rotatably provided between the upper sides of the front and rear supporting plates 601. The upper side of the rod 301 is slidingly connected, the left end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com