Optical lens centrifugal cleaning machine

A centrifugal cleaning, optical lens technology, applied in the direction of cleaning flexible objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of spray effect, direct particle effect, scratches, etc., to reduce the possibility of scratches performance, high spray utilization, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

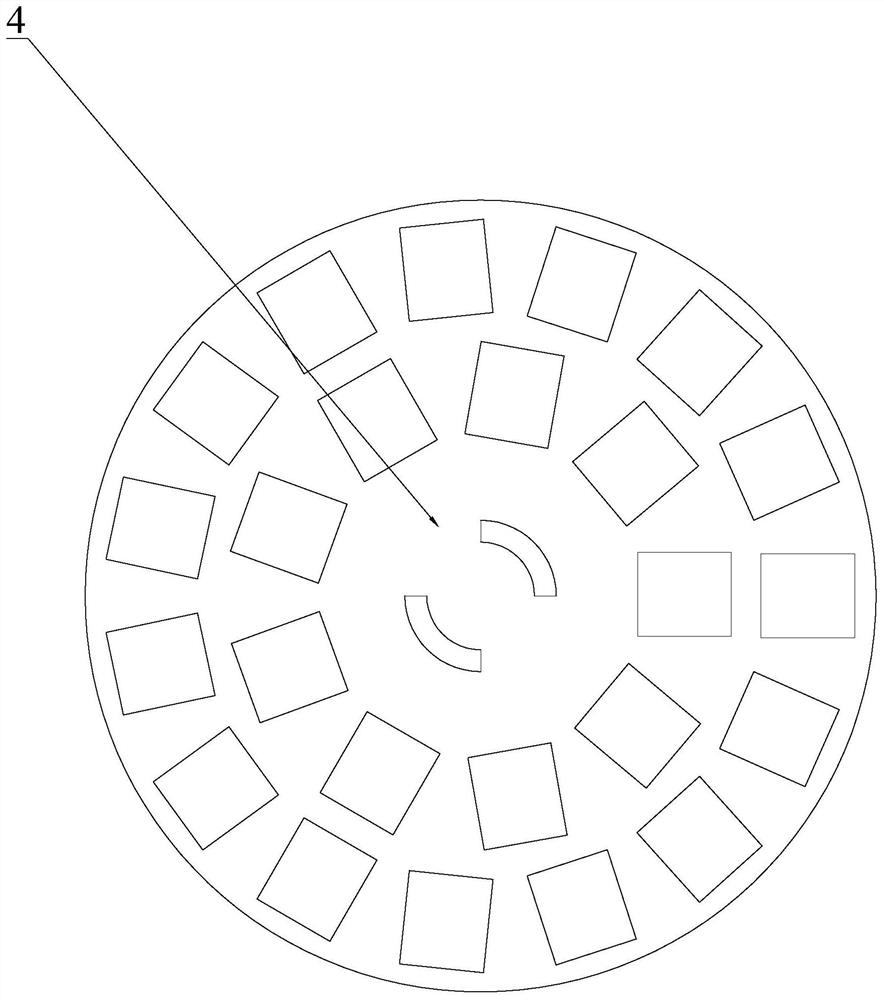

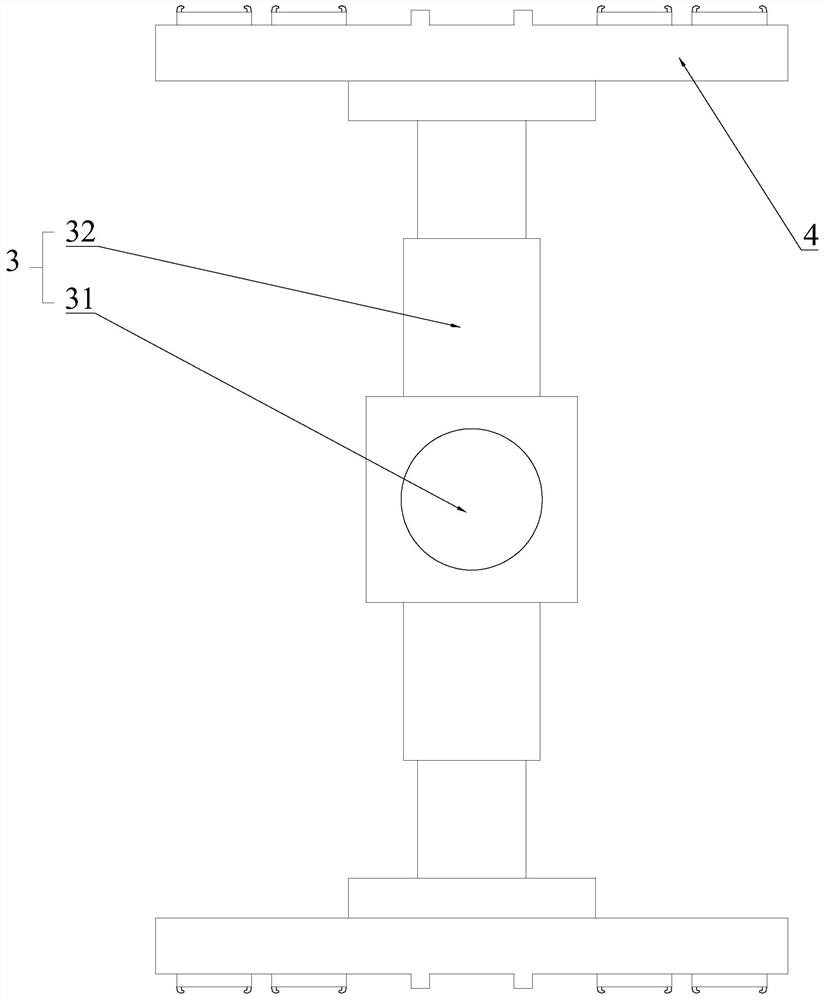

[0016] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the optical lens centrifugal cleaning machine of the present invention includes a housing 1, the housing 1 is provided with an inlet 11 and an outlet 12, and the inlet 11 and the outlet 12 are provided with conveying tracks, and also includes a set The loading carousel 4 and the rotating mechanical arm 3 in the housing 1 also include a rotating shaft 5 located at the lower side of the loading carousel 4, and a spray assembly 6 is fixedly connected to the rotating shaft 5, and the spray assembly 6 It includes a spray body 62 fixedly connected to the rotating shaft 5 and nozzles 61 arranged along the circumference of the spray body 62. The spray body 62 is detachably connected to the load carousel 4. The spray body 62 is connected to the load The turntable 4 is limited in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com