Seven-axis linkage numerical control polishing machine

A polishing machine and linkage technology, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as difficulty in realization and complex structure, improve polishing quality and stability, improve production efficiency and economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a further detailed description of the seven-axis linkage CNC polishing machine of the present invention in conjunction with the accompanying drawings;

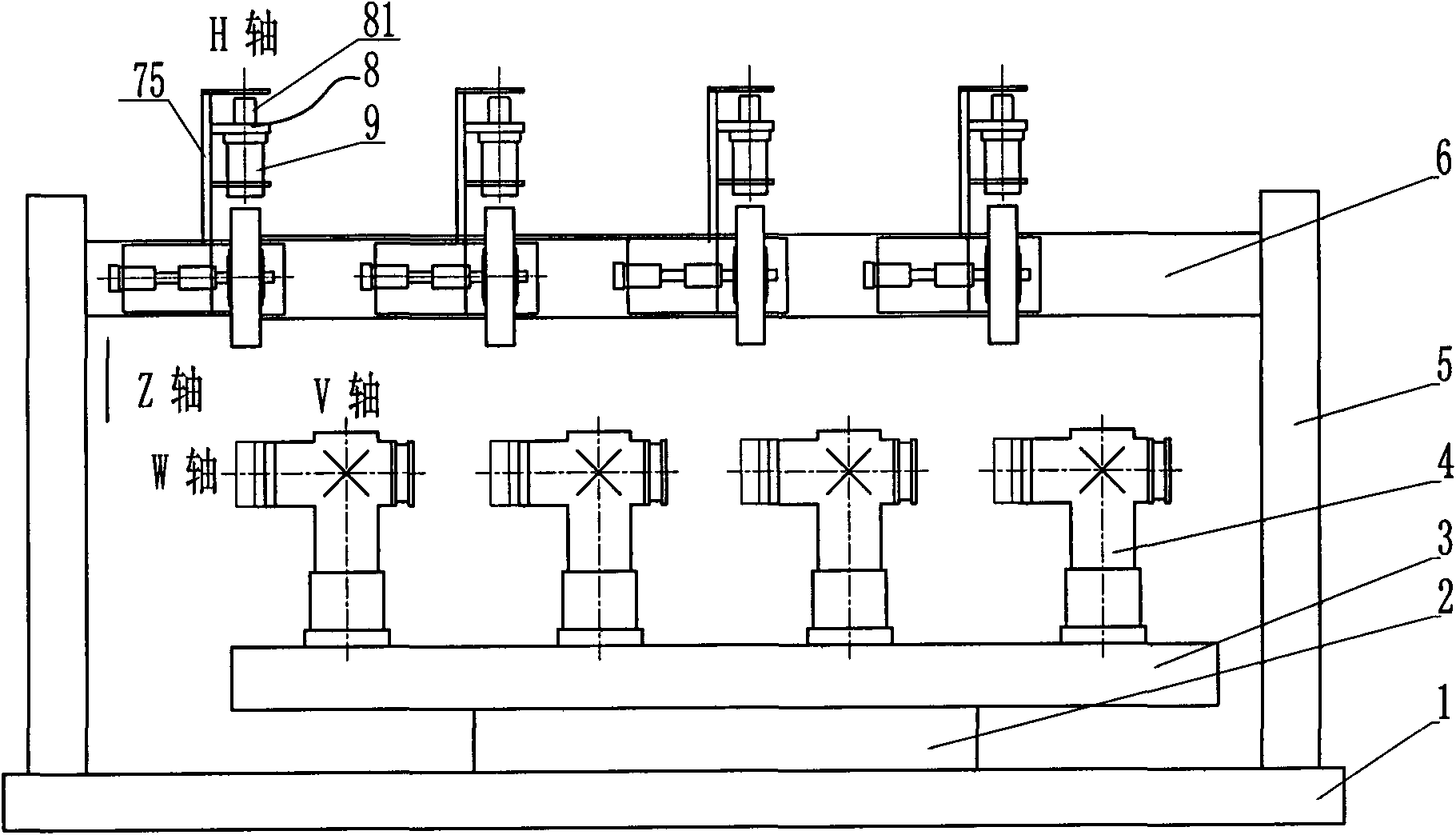

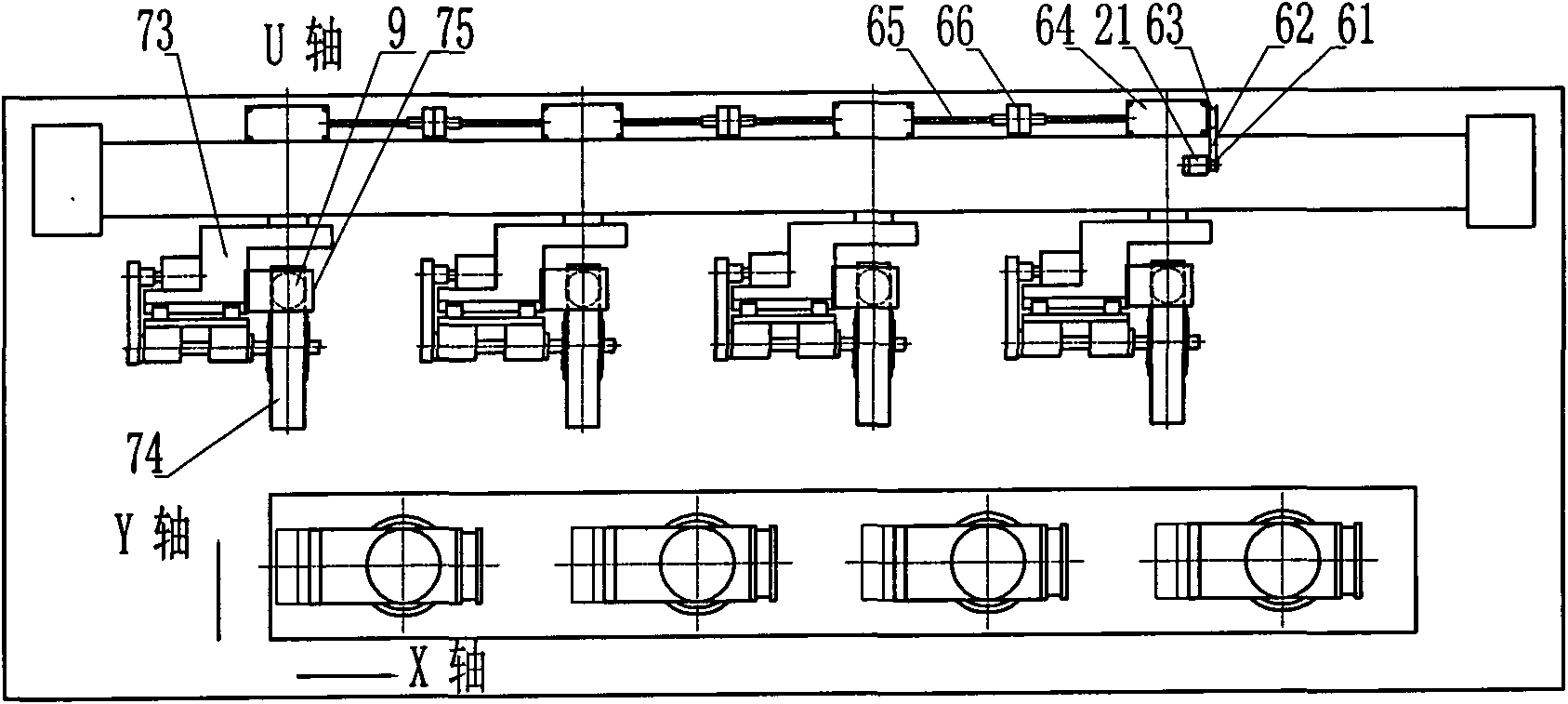

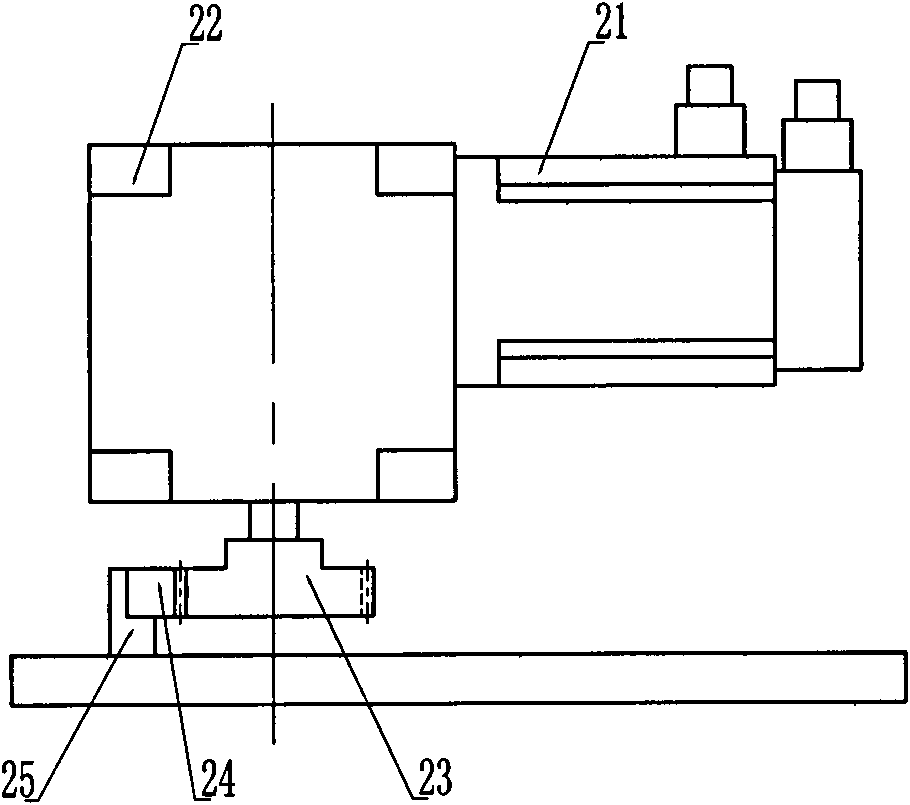

[0026] Such as figure 1 , figure 2 The seven-axis linkage CNC polishing machine of the present invention mainly consists of a large base 1, a movable base 2, a workbench 3, a three-way swivel seat 4, a left and right column 5, a crossbeam 6, a head frame 73, a polishing wheel 74 and the like. The movable base 2 moves linearly along the X-axis on the large base 1; the worktable 3 moves linearly along the Y-axis on the movable base 2; the three-way rotary seat 4 rotates around the V-axis on the worktable 3; Rotate around the W axis on the slewing seat 4; the beam 6 moves linearly along the Z axis on the column 5; the head frame 73 drives the polishing wheel 74 to rotate around the U axis, and all the above six movements are driven by servo motors independent of each other , through the linear motion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com