Variable cross-section outer cylinder surface sander suitable for timber

A technology of variable section and outer cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

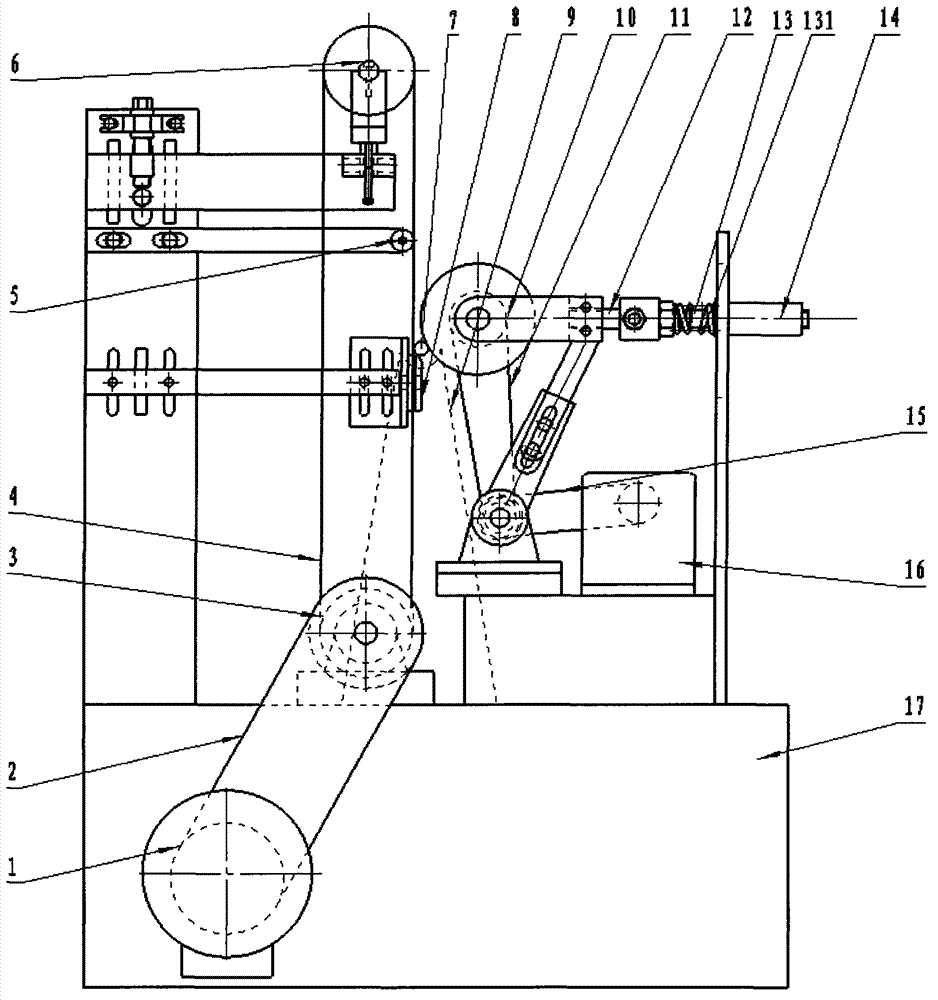

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

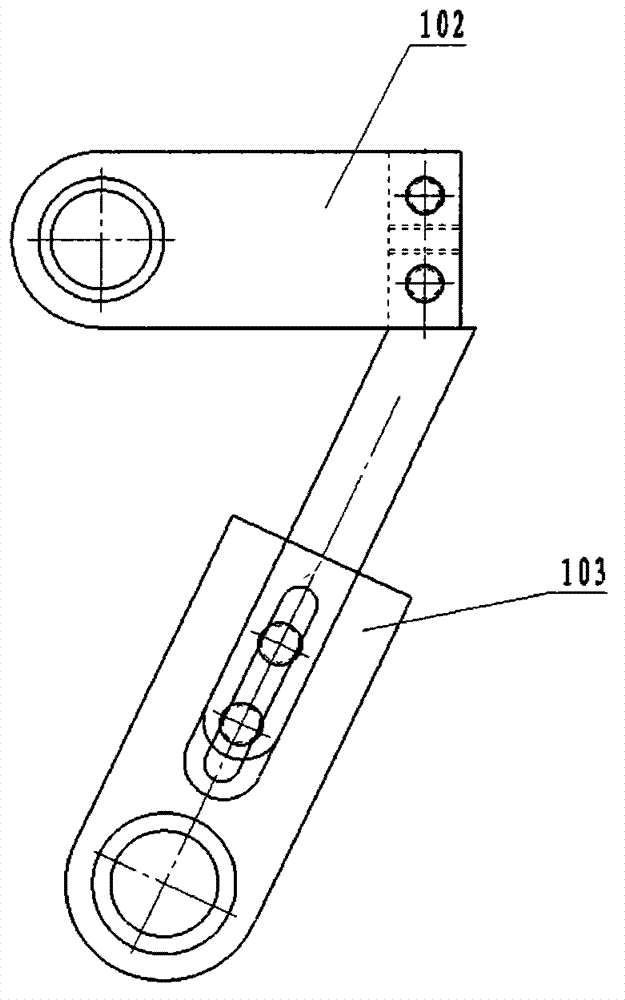

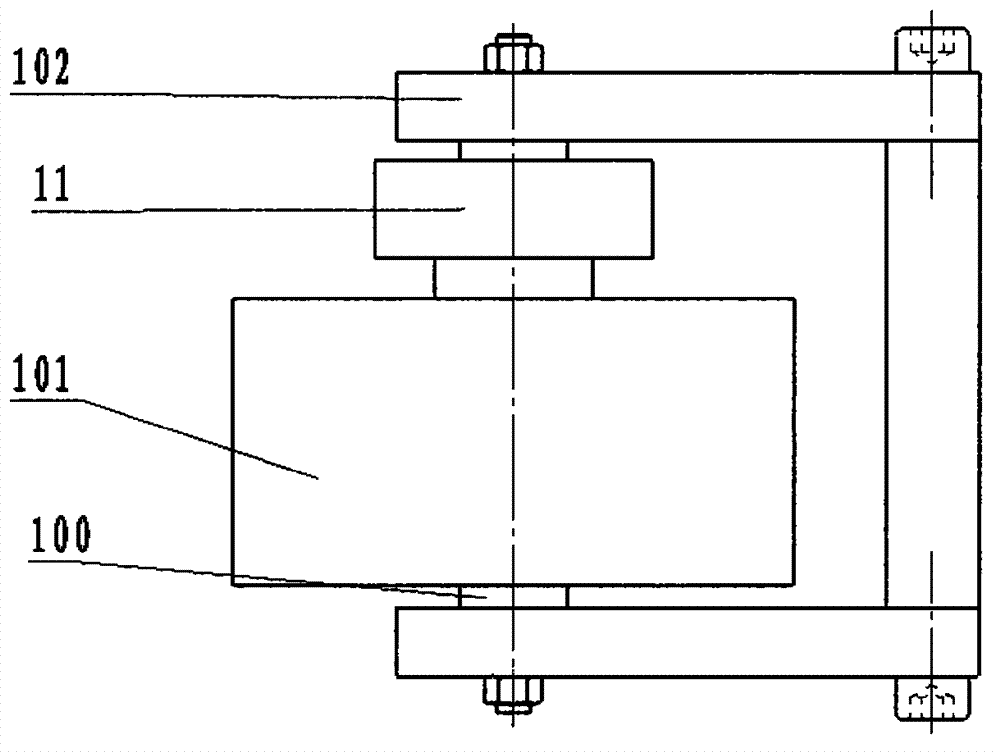

[0017] Refer to attached Figure 1-8 , the main structure of the present invention is suitable for a variable cross-section outer cylindrical surface sander for wood, including a motor 1, a V-belt transmission mechanism 2, an abrasive belt driving wheel 3, an abrasive belt 4, an abrasive belt tensioner 5, and an abrasive belt from Driving wheel 6, feeding mechanism 8, receiving hopper 9, pressure wheel mechanism 10, synchronous belt transmission mechanism 11, rod end joint bearing 12, screw rod 13, hand wheel 14, V-belt transmission mechanism 15, motor 16 and frame 17.

[0018] The feeding mechanism 8 includes a connecting arm 81 , a right-angle bracket 82 , a feeding plate 83 and a connecting plate 84 . The feeding plate 83 is connected with the connecting plate 84; the abrasive belt 4 passes through the gap between the feeding plate 83 and the connecting plate 84; the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com