Metal polishing solution and preparation method and application thereof

A polishing liquid and metal technology, applied in the field of metal polishing liquid and its preparation, can solve the problems of low cutting efficiency, cost reduction, unfavorable environmental protection, etc., and achieve the effects of excellent suspension stability, excellent polishing quality, and reduced formula cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

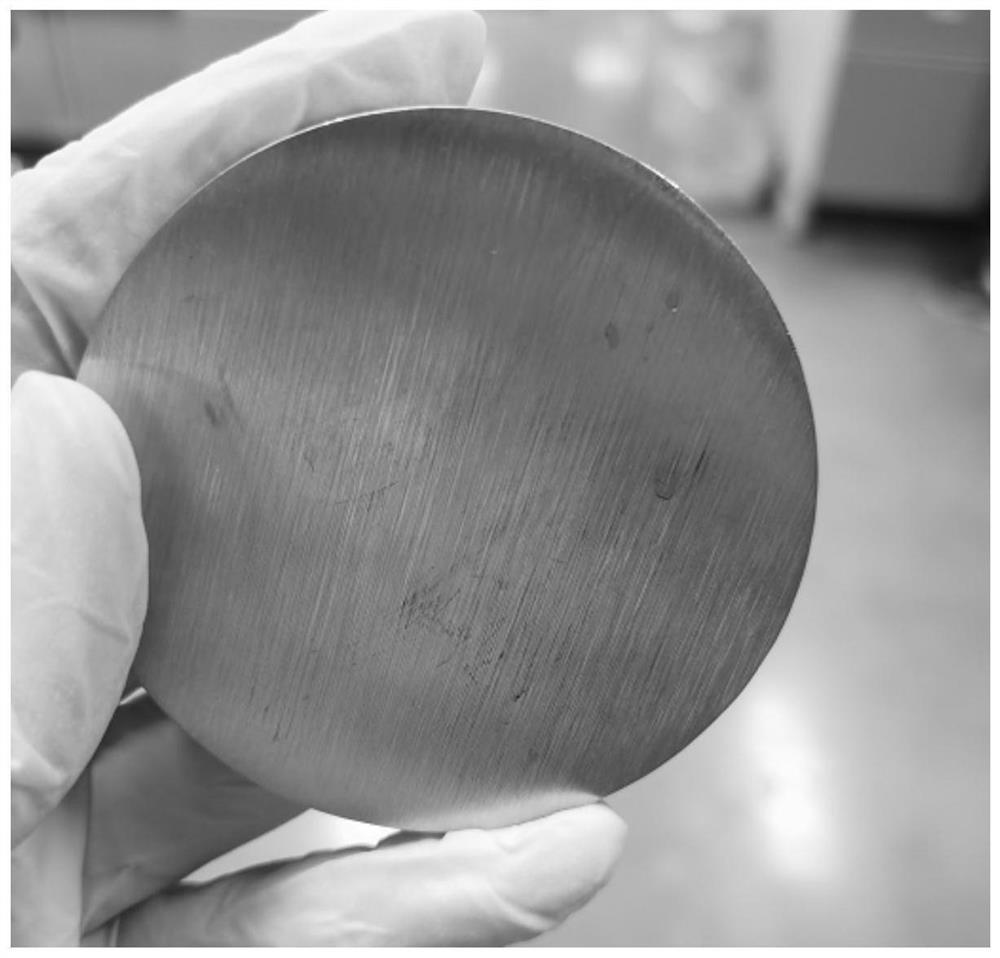

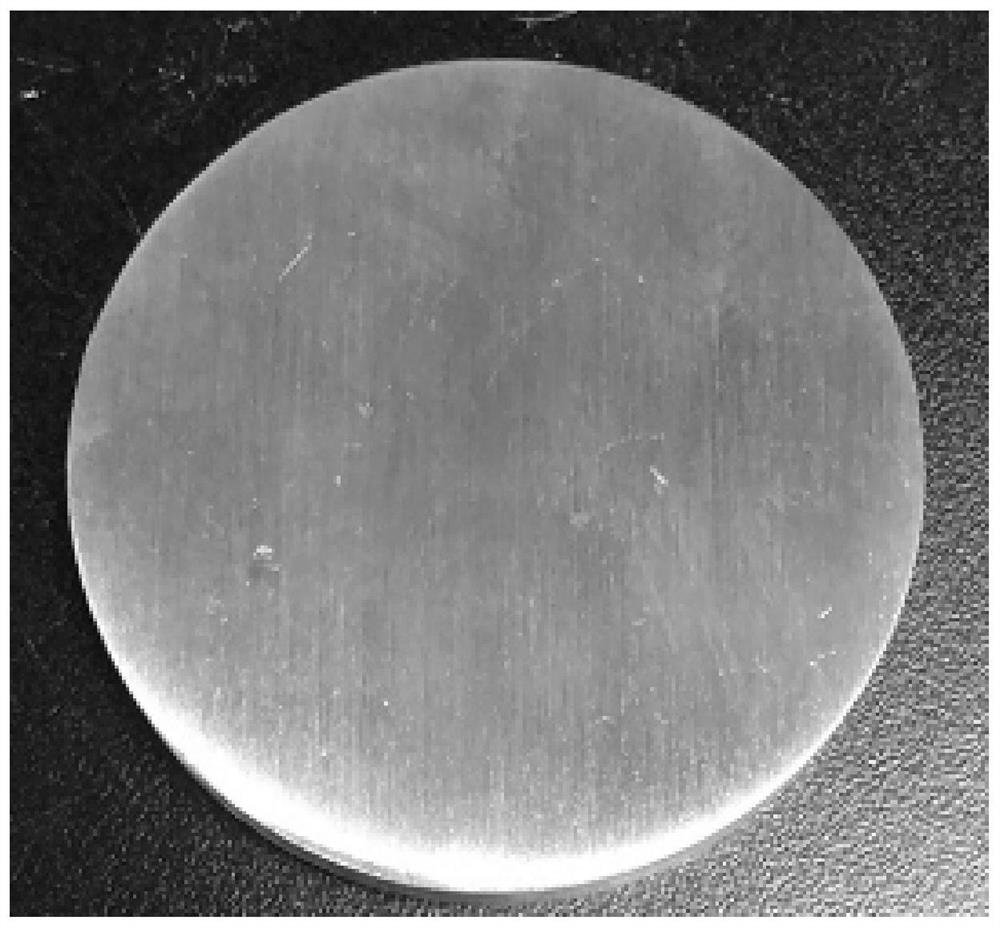

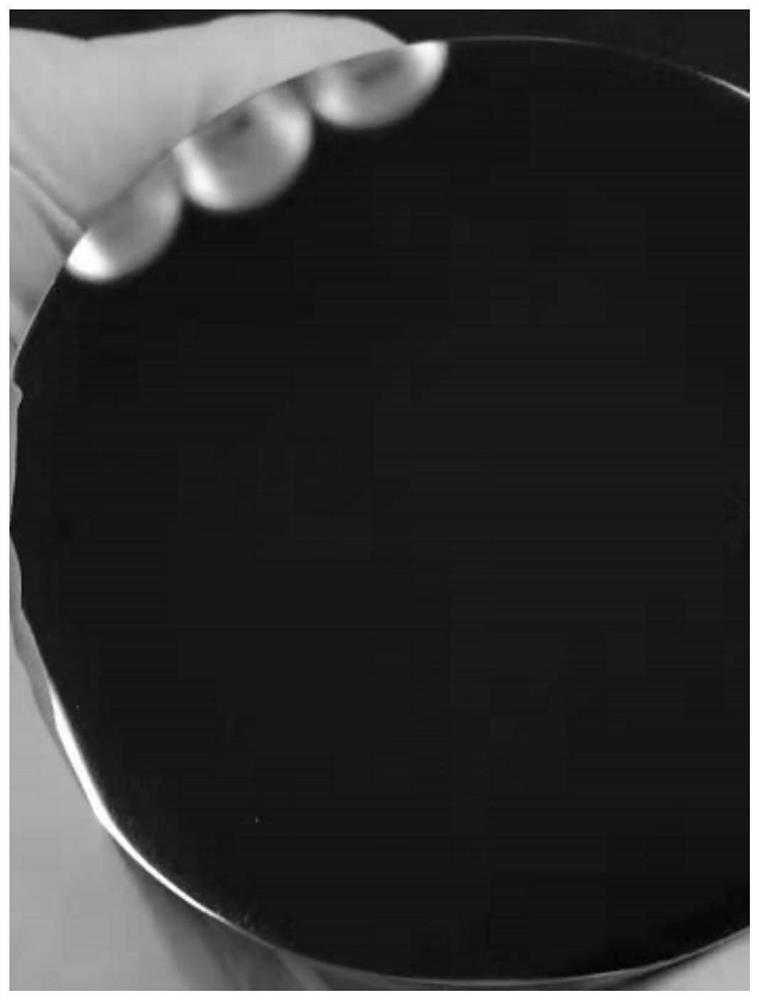

Image

Examples

Embodiment 1

[0051] The present embodiment provides a metal polishing liquid and a preparation method thereof, and the preparation method of the metal polishing liquid comprises the following steps:

[0052] 1) Select commercially available common pseudo-boehmite (Na content is about 0.37%, purchased from Shandong Aluminum Industry) as raw material; put the pseudo-boehmite into a kiln for calcination, the calcination temperature is 1280 ° C, and monitor the particles The specific surface area of the material, and monitor the grain size with HSEM, the specific surface area of the material after calcination is 4.05m 2 / g, the grain size is 98nm;

[0053] The calcined material is wet-milled with a stirring mill (stirring milling beads: spherical, φ=3mm) to control the solid content to about 43.8%, monitored by a laser particle size analyzer, and ball milled to a particle size of D 50 About 1.3μm;

[0054] 2) Commercially available common pseudo-boehmite (Na content 0.37%) is wet-milled ...

Embodiment 2

[0058] The present embodiment provides a metal polishing liquid and a preparation method thereof, and the preparation method of the metal polishing liquid comprises the following steps:

[0059] 1) Select commercially available high-purity aluminum hydroxide (purity > 99.9%, purchased from Shandong Aluminum Industry) as raw material; put high-purity aluminum hydroxide into a kiln for calcination, the calcination temperature is 1250 ° C, monitor the specific surface area of the particles, and use HSEM to monitor Grain size, the specific surface area of the material after calcination is 5.74m 2 / g, the grain size is 92nm;

[0060] The calcined material is wet-milled by stirring mill (stirring milling beads: spherical, φ=3mm), the solid content is controlled to be about 44.0%, monitored by laser particle size analyzer, and ball milled to particle size D 50 About 1.1 μm;

[0061] 2) Commercially available common pseudo-boehmite (Na content 0.37%) is wet-milled with a vibrati...

Embodiment 3

[0065] The present embodiment provides a metal polishing liquid and a preparation method thereof, and the preparation method of the metal polishing liquid comprises the following steps:

[0066] 1) select commercially available common pseudo-boehmite (Na content is about 0.37%) as raw material; put the pseudo-boehmite into the kiln for calcination, the calcination temperature is 1180°C, monitor the specific surface area of the particles, and use HSEM Monitor the grain size, the specific surface area of the calcined material is 7.43m 2 / g, the grain size is 90.9nm;

[0067] The calcined material is wet-milled with a stirring mill (stirring milling beads: spherical, φ=3mm), and the solid content is controlled to be about 40.2%, monitored by a laser particle size analyzer, and the ball is milled to a particle size of D 50 About 0.93μm;

[0068] 2) Commercially available common pseudo-boehmite (Na content 0.37%) is wet-milled with a vibration mill (milling beads: cylindrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com