Oil-based drilling mixture reinjection slurry composition, oil-based drilling mixture reinjection slurry and preparation method and application thereof

An oil-based drilling and oil-based drilling fluid technology, applied in wellbore/well components, earthwork drilling, wellbore flushing, etc., can solve the problem of unclear stability time of downhole slurry, inaccurate component dosage, poor suspension stability, etc. problem, to reduce the risk of bottom hole sedimentation and blasthole blockage, good suspension stability, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

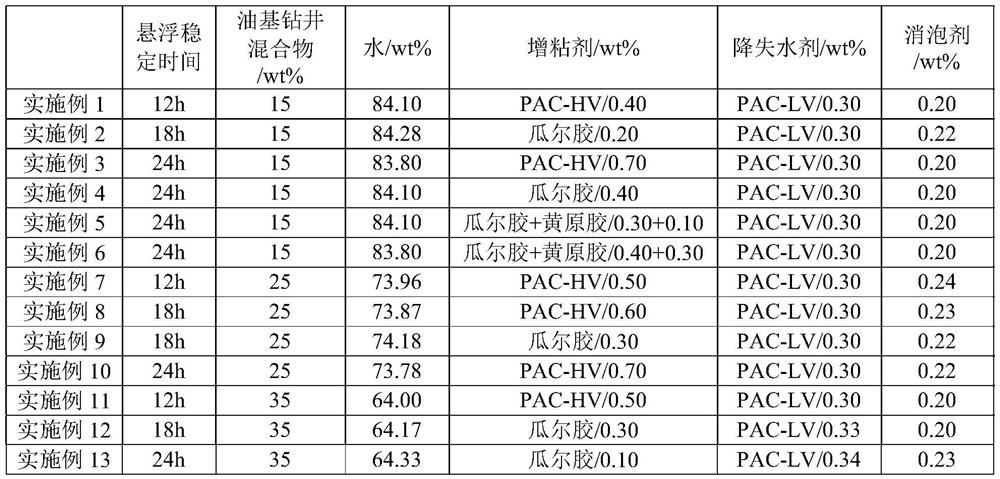

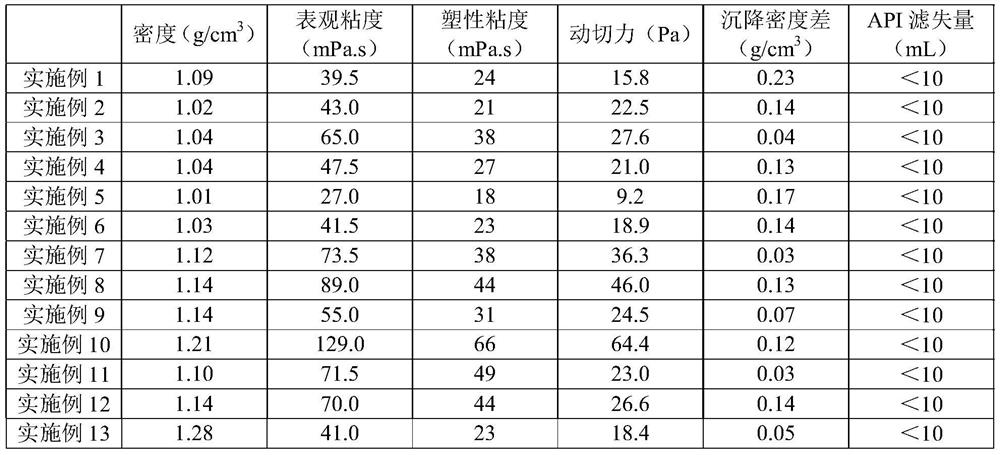

[0082] This example is used to illustrate that the oil-based drilling mixture re-injection composition according to the present invention is prepared according to the formula and process parameters in Table 1, and the oil-based drilling mixture re-injection is prepared according to the following method.

[0083] The preparation method of the oil-based drilling mixture back grouting comprises the following steps:

[0084] (1) At room temperature, stir the oil-based drilling mixture and water in a tall beaker at a speed of 1000 rpm for 10 minutes to obtain the first mixture;

[0085] (2) At room temperature, after stirring the first mixture with the viscosifier, fluid loss reducer, and defoamer at a speed of 1000 rpm for 15 minutes, the mixture was placed in a mill and ground for 10 minutes to obtain an oil-based drilling mixture Back grouting.

Embodiment 2-13

[0087] In the case of no special instructions, embodiment 2-embodiment 13 adopts the same flow process as embodiment 1, and the difference is:

[0088] The content of different oil-based drilling mixtures and the required suspension stability time are different, and the type and amount of each component in the composition used are different. See Table 1 for details.

[0089] Table 1

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com