Polyamide flashing waterproof coating for zippers and preparation method of waterproof coating

A waterproof coating, polyamide technology, applied in the coating and other directions, can solve the problems of the zipper being undurable, the flashing material is exposed, the coating is broken, etc., and the preparation method is simple and efficient, avoiding excessive shearing, and improving compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

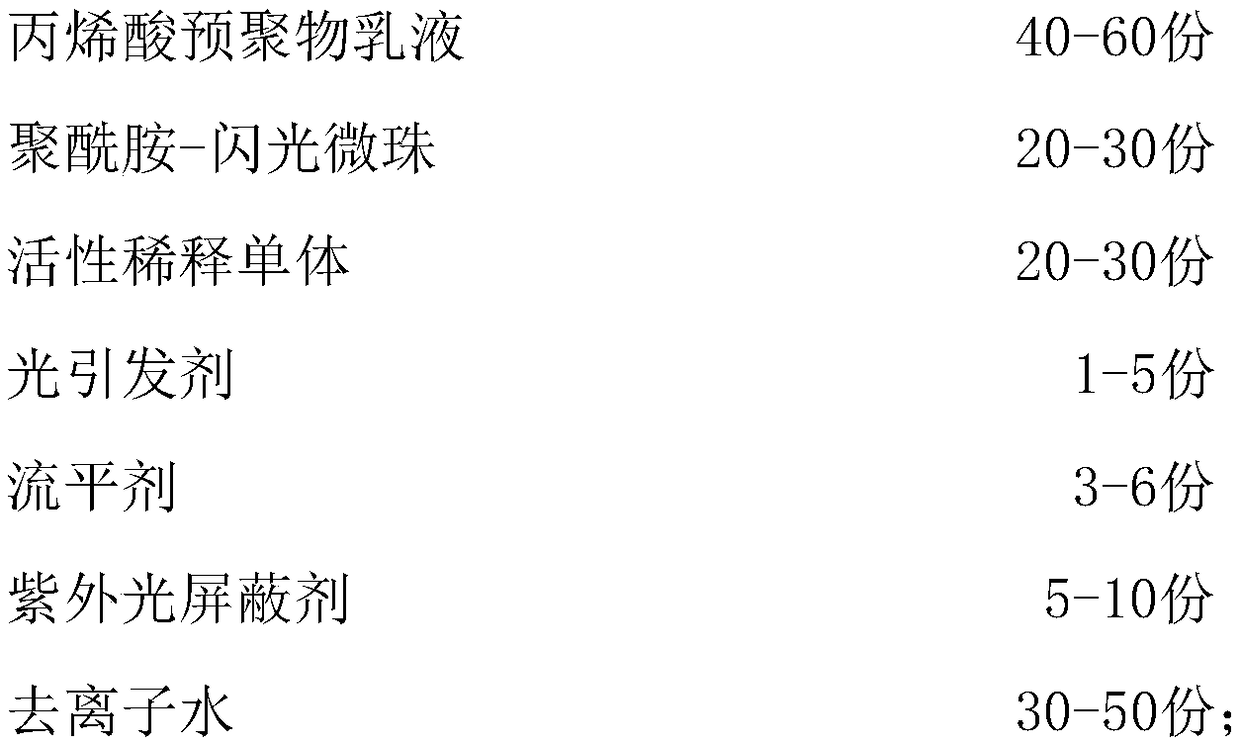

[0028] A polyamide flash waterproof coating for slide fasteners, comprising the following raw materials in parts by weight:

[0029]

[0030] Wherein, the polyamide-glitter microbeads are composed of glitter microbeads and a polyacrylamide layer covering the glitter microbeads.

[0031] Wherein, the flashing microbeads are micron-scale prism-pyramid monomers.

[0032]Wherein, the preparation method of the polyamide-glitter microbeads comprises the following steps: mix the glitter microbeads, the inorganic peroxide initiator and the aqueous acrylamide solution at a weight ratio of 15:2:50, heat up to 85° C., and keep the temperature for 3 hours. , filtered and dried to obtain the polyamide-glitter microbeads, wherein the mass fraction of acrylamide in the polyacrylamide aqueous solution is 25%.

[0033] Wherein, the thickness of the polyacrylamide layer is 14.3 μm.

[0034] Wherein, the inorganic peroxide initiator is composed of ammonium persulfate and potassium persulfat...

Embodiment 2

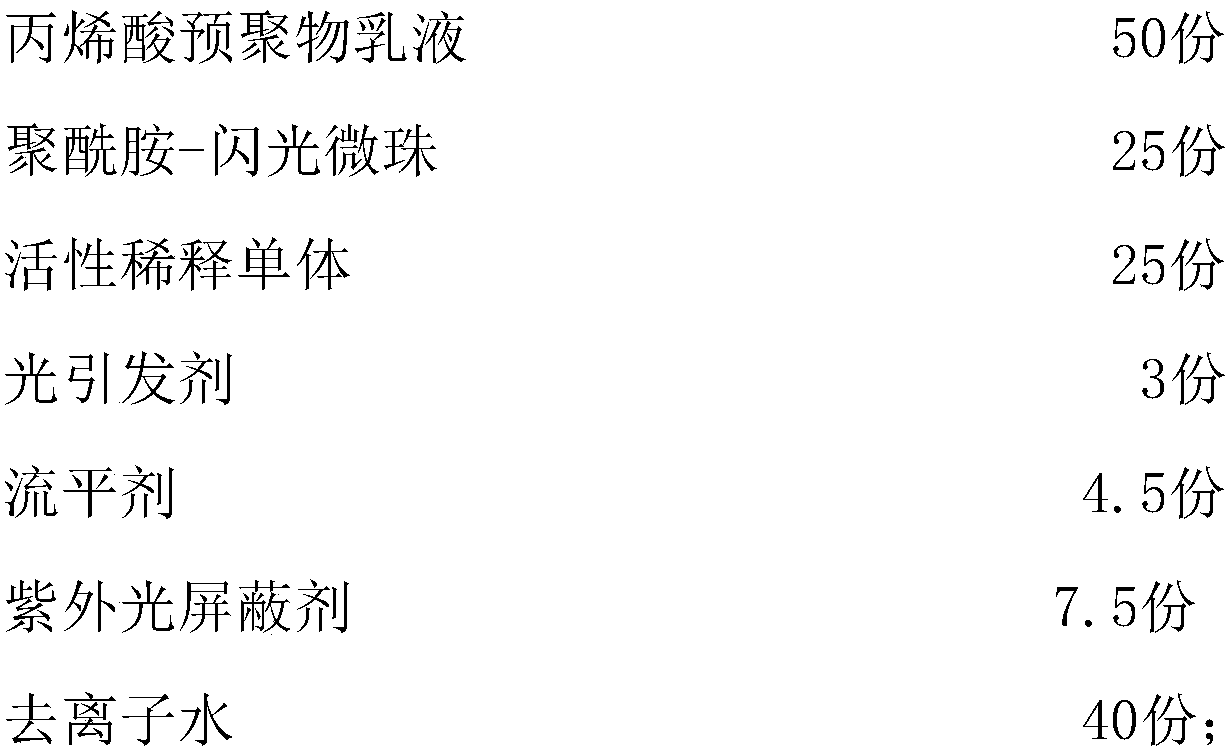

[0041] A polyamide flash waterproof coating for slide fasteners, comprising the following raw materials in parts by weight:

[0042]

[0043] Wherein, the polyamide-glitter microbeads are composed of glitter microbeads and a polyacrylamide layer covering the glitter microbeads.

[0044] Wherein, the flashing microbeads are micron-scale prism-pyramid monomers.

[0045] Wherein, the preparation method of the polyamide-glitter microbeads comprises the following steps: mix the glitter microbeads, the inorganic peroxide initiator and the aqueous acrylamide solution at a weight ratio of 10:1:40, heat up to 80° C., and keep the temperature for 2 hours. , filtered and dried to obtain the polyamide-glitter microbeads, wherein the mass fraction of acrylamide in the polyacrylamide aqueous solution is 20%.

[0046] Wherein, the thickness of the polyacrylamide layer is 12.4 μm.

[0047] Wherein, the inorganic peroxide initiator is composed of ammonium persulfate and potassium persulfa...

Embodiment 3

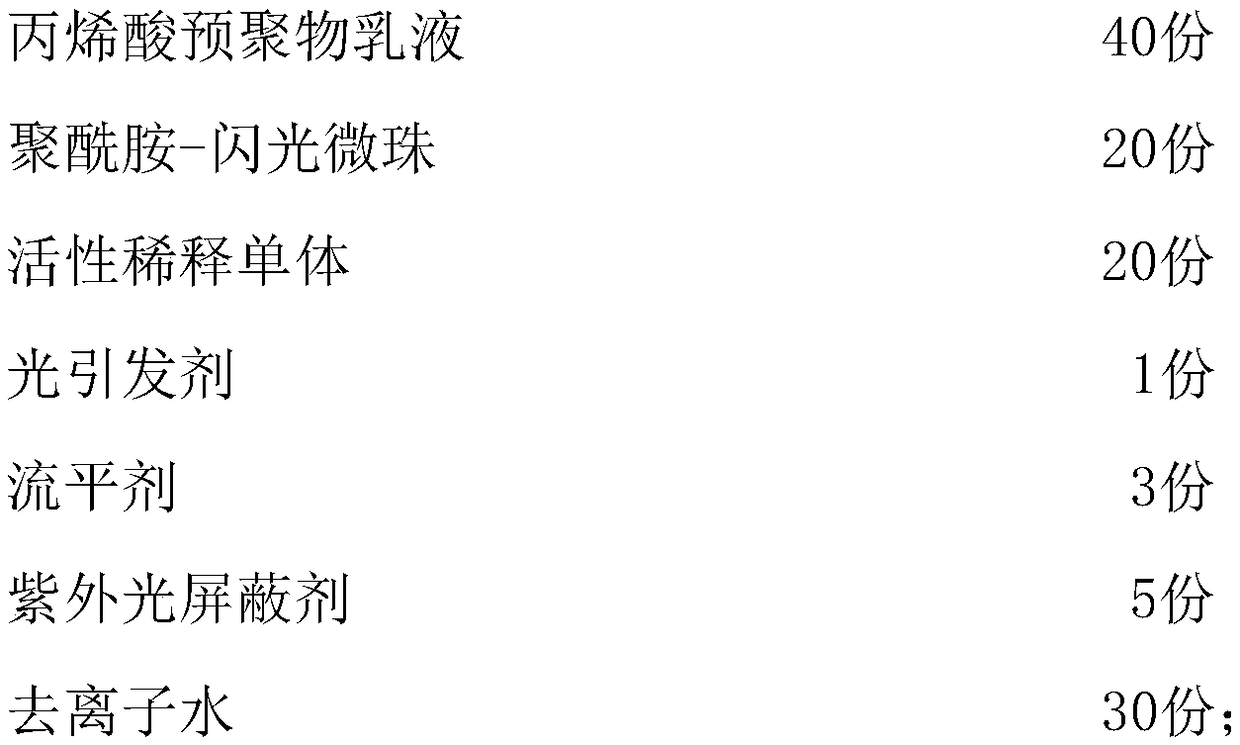

[0054] A polyamide flash waterproof coating for slide fasteners, comprising the following raw materials in parts by weight:

[0055]

[0056] Wherein, the polyamide-glitter microbeads are composed of glitter microbeads and a polyacrylamide layer covering the glitter microbeads.

[0057] Wherein, the flashing microbeads are micron-scale prism-pyramid monomers.

[0058] Wherein, the preparation method of the polyamide-glitter microbeads comprises the following steps: mix the glitter microbeads, the inorganic peroxide initiator and the acrylamide aqueous solution at a weight ratio of 20:3:60, heat up to 90° C., and keep the temperature for 4 hours. , filtered and dried to obtain the polyamide-glitter microbeads, wherein the mass fraction of acrylamide in the polyacrylamide aqueous solution is 30%.

[0059] Wherein, the thickness of the polyacrylamide layer is 18.3 μm.

[0060] Wherein, the inorganic peroxide initiator is composed of ammonium persulfate and potassium persulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com