Polishing process for ultrathin sapphire wafers

A sapphire wafer and process technology, which is applied to surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of inability to meet the polishing requirements of sapphire wafers, long polishing time for polished sapphire wafers, etc., and achieve stable and reliable polishing quality. , The effect of shortening polishing time and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

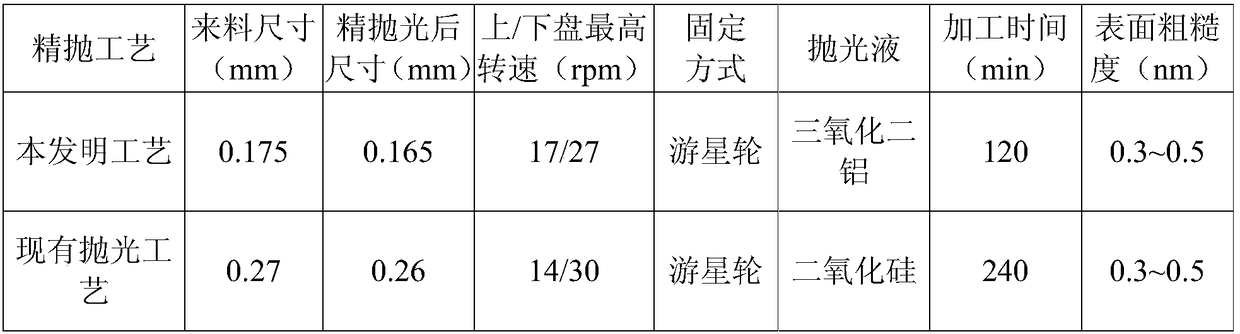

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below through specific examples, but the present invention can be implemented in many different ways defined and covered by the claims.

[0022] A kind of polishing process of ultra-thin sapphire wafer of the present invention, the thickness of the product after ultra-thin sapphire wafer polishing is 0.1~0.2mm, it is characterized in that, polishing process comprises the following steps: 1), the sapphire wafer obtained by cutting is grouped by thickness , so that the thickness difference of multiple sapphire wafers in the same group is within 0.015mm; 2), rough throwing preparation stage: provide an adsorption pad, which is provided with a plurality of cavity holes for placing sapphire wafers, the cavity holes The depth is lower than the thickness of the sapphire wafer after the rough polishing step. Wet the cavity hole with clean water, and then put the sapphire wafer into the cavity hole so that the two are relatively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com