Multi-workstation single-robot abrasive-belt-type polishing machine

A technology for robotic abrasive belts and polishing machines, which is applied in the direction of abrasive belt grinders, grinding/polishing equipment, grinding/polishing safety devices, etc. Long transfer stroke and other problems, to achieve the effect of reducing the machine footprint, shortening the transfer stroke, and improving the polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

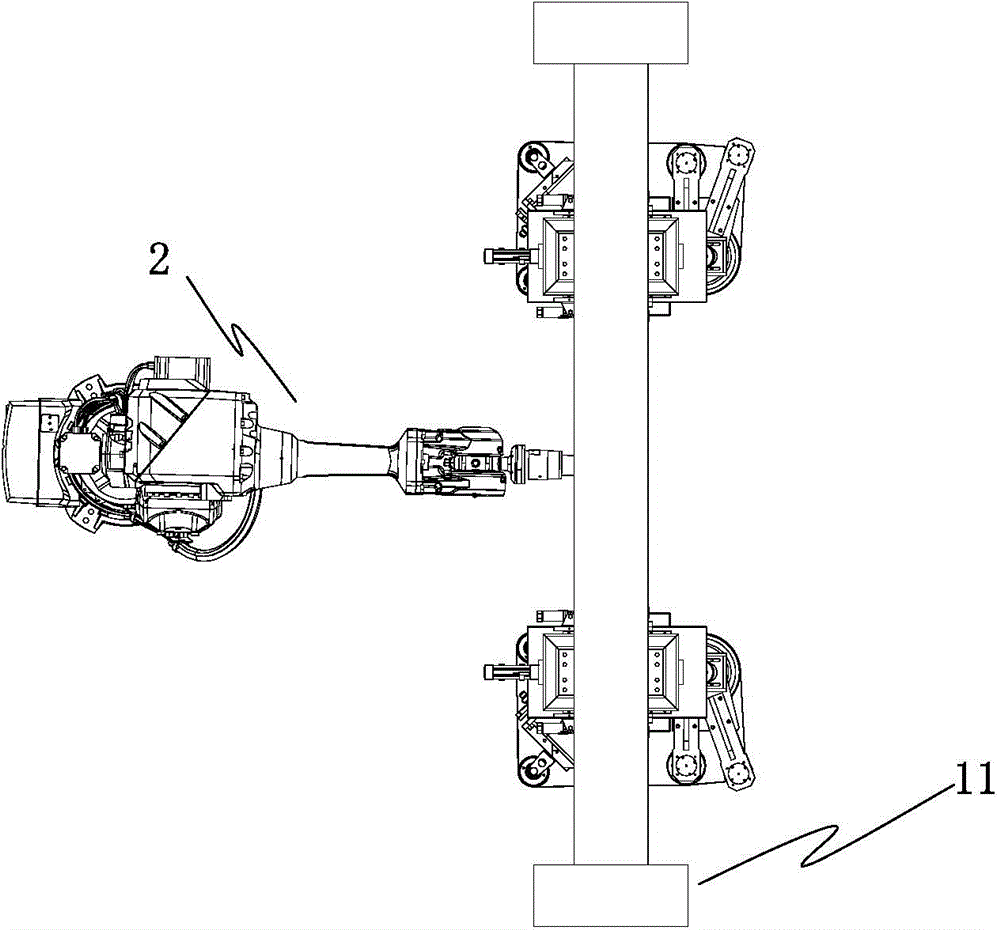

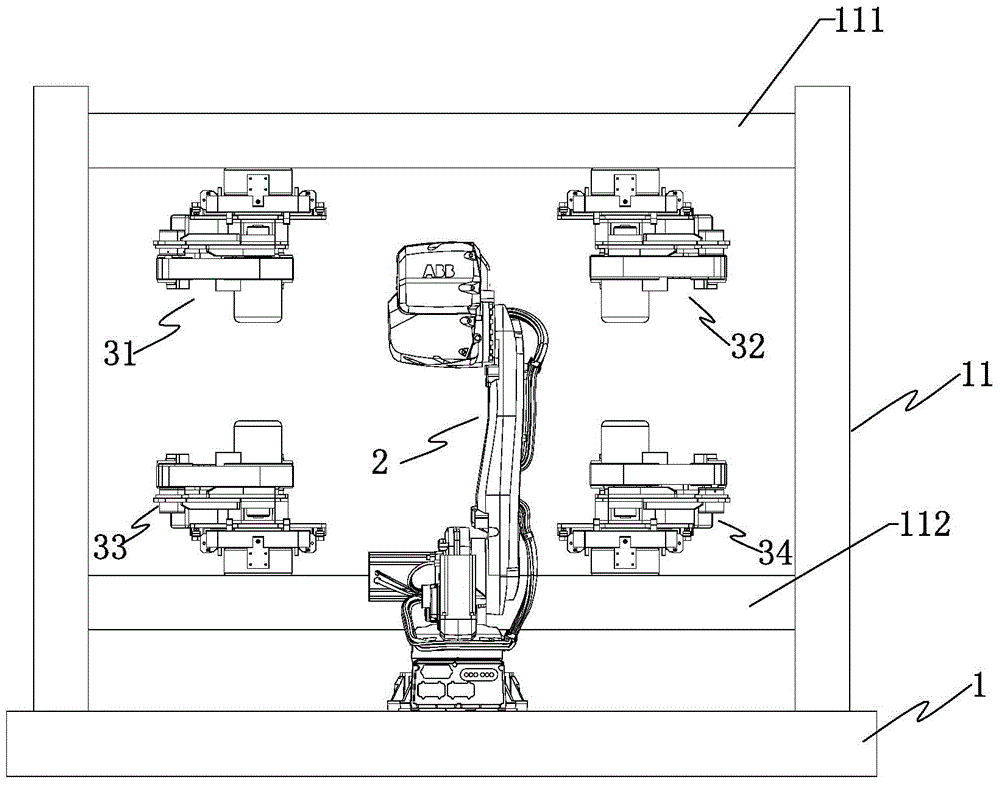

[0024] Such as Figures 1 to 5 As shown, the multi-station single-robot abrasive belt polishing machine of the present invention includes an organic base 1 and a head support 11 arranged on the base. The head support 11 is in the shape of a "mouth" frame structure as a whole. The upper beam 111 and the lower beam 112 of the structure are respectively symmetrically provided with two polishing heads, and the above-mentioned four polishing heads 31, 32, 33, 34 also form a "mouth"-shaped layout structure, and one side of the head support 11 is arranged There is a gripper robot 2 .

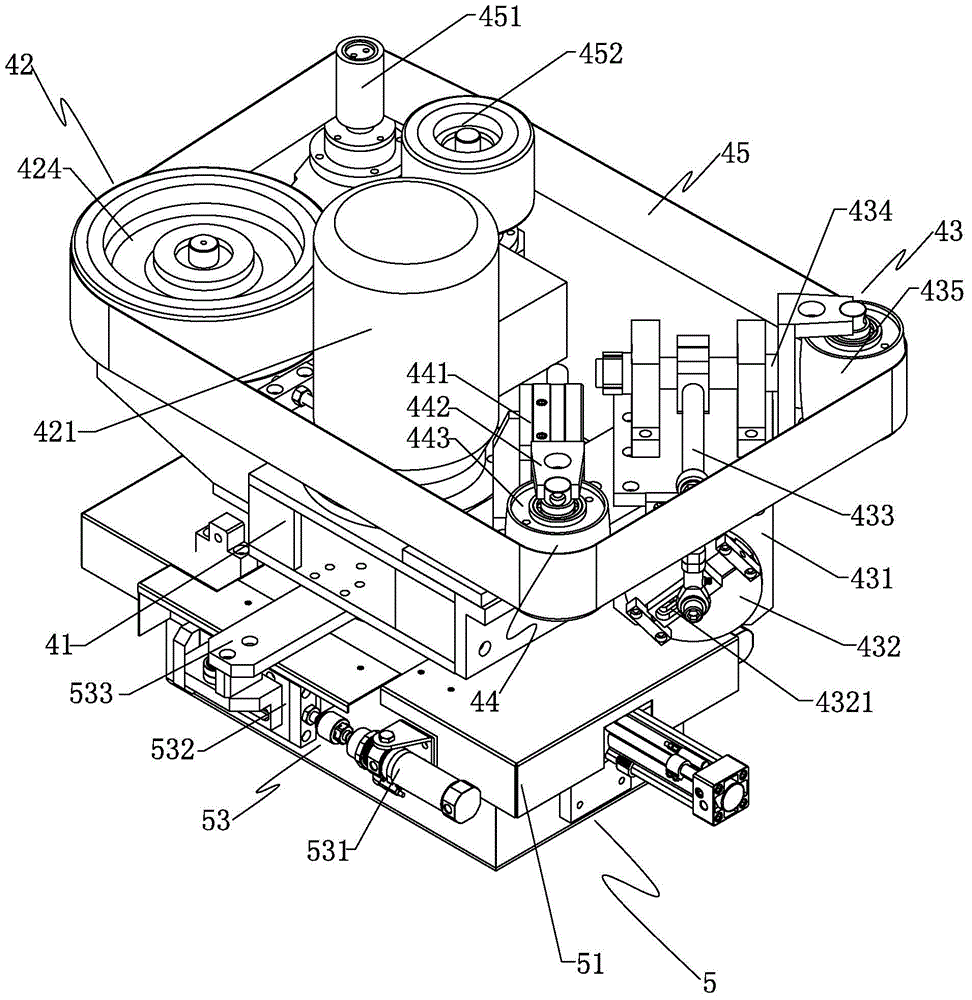

[0025] Each of the above-mentioned polishing heads is provided with a headstock 41, and one side of the headstock 41 is provided with an abrasive belt driving assembly 42, an abrasive belt oscillating assembly 43, an abrasive belt tensioning assembly 44, and polishing pads surrounding the above-mentioned assemblies. Abrasive belt 45, headstock swing assembly 5 and rotating assembly 6 are arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com