An automatic device applied to the assembly and reclaiming of the logic board of a single-phase electric energy meter

A technology of automatic devices and electric energy meters, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of reducing work intensity, high work intensity, and inconvenient retrieving materials, so as to reduce labor intensity, reduce labor intensity, improve Effect of work steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

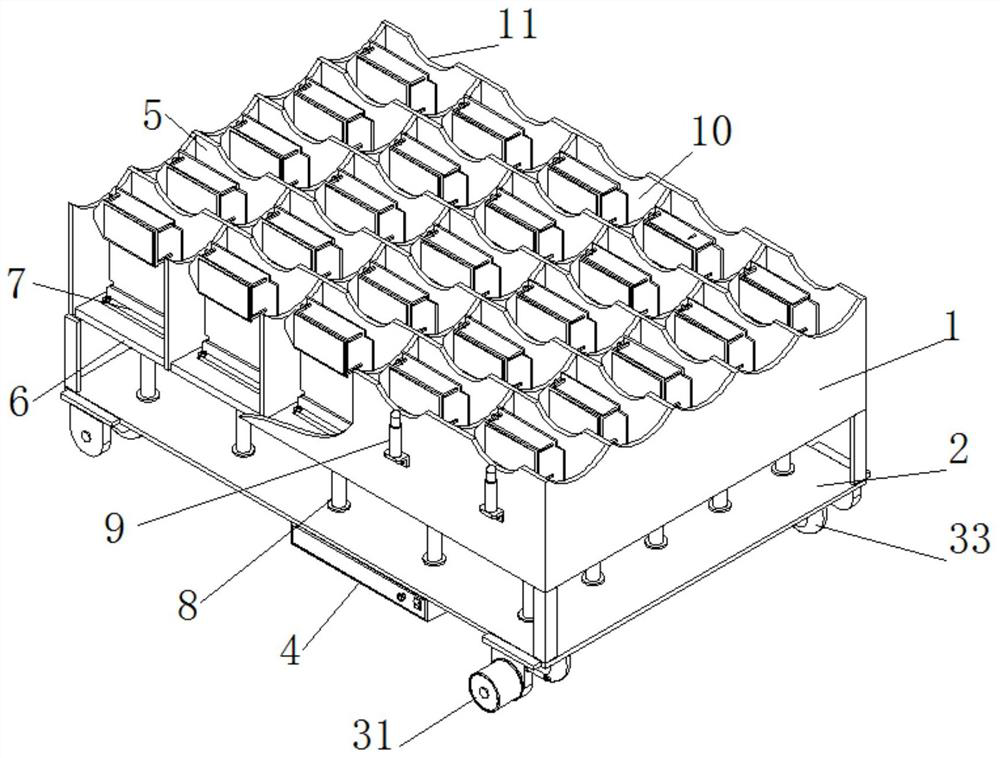

[0028] An automatic device for assembly and retrieving of logic boards of single-phase electric energy meters, such as figure 1 As shown, it includes box body 1 and bottom bracket 2. Box body 1 is made of anti-static foam material; bottom bracket 2 is provided under box body 1, and bottom bracket 2 is made of bakelite; bottom bracket 2 is equipped with a moving mechanism And the control mechanism 4, the moving mechanism is used to move the device, and the control mechanism is used to control the moving mechanism.

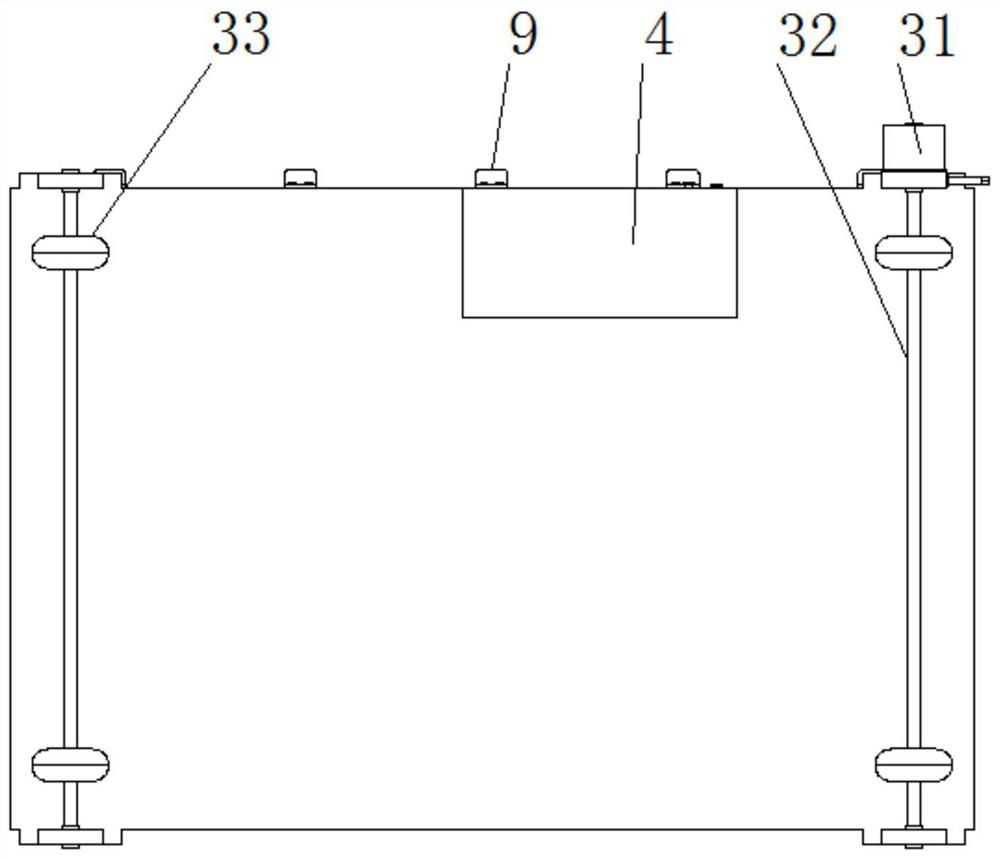

[0029] Such as figure 2 As shown, the moving mechanism includes a servo motor 31, a rotating shaft 32 and a roller 33. A rotating shaft 32 is installed below the bottom bracket 2. A roller 33 is arranged on the rotating shaft 32. The rotating shaft 32 drives the roller 33 to rotate; one end of the rotating shaft 32 is connected to the servo motor 31 , the servo motor 31 realizes the rotation of the rotating shaft 32 .

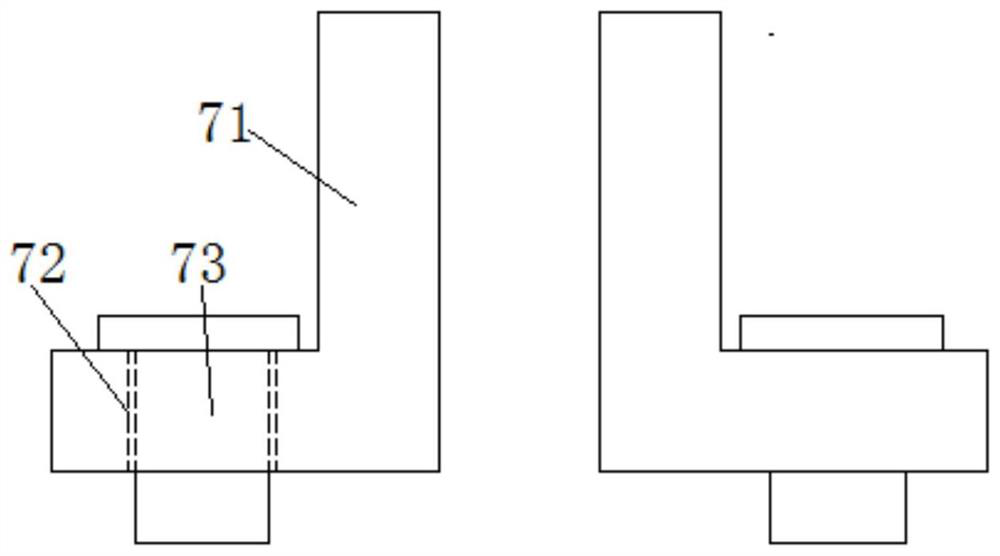

[0030] Such as Figure 7 As shown, the con...

Embodiment 2

[0038] Such as Figure 5 and Figure 7 As shown, a return spring 86 is provided between the bottom plate 6 and the bottom support 2 , and the return spring 86 is used to move the bottom plate 6 .

[0039]When the back-moving spring 86 played a supporting role, when the material was not taken, the controller controlled the electromagnet 84 to be energized, and the electromagnet 84 was energized to generate magnetism. The magnetic pole of the electromagnet 84 after energization was opposite to that of the permanent magnet 85. 1. Under the action of the fixing mechanism 7 and the weight of the logic board, the logic board is firmly placed in the storage compartment 10. At this time, the force of opposite sex attraction+the weight of each component>the resistance of the return spring 86+the frictional resistance received by the movement of the bottom plate 6; When the laser sensor 9 transmits the signal to the controller, the controller makes the counter count; after the counting...

Embodiment 3

[0041] On the basis of Embodiment 2, when the back-moving spring 86 plays a tensioning role, when the material is not taken, the back-moving spring 86 pulls the electromagnet 84 and the permanent magnet 85 together; when taking the material, the controller makes the electromagnet 84 energized Generate magnetism, the magnetic poles of the electromagnet 84 after electrification are the same as the magnetic poles of the permanent magnet 85; under the effect of the same-sex repulsion, the electromagnet 84 moves the permanent magnet 85 upwards, the return spring 86 expands, and the force of the same-sex repulsion > the corresponding component The self-weight + the frictional resistance received by the bottom plate 6 when moving + the resistance of the return spring 86, thereby making the logic board move and be easy to take out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com