Polishing layer of chemical-mechanical polishing pad and application of polishing layer

A chemical mechanical and polishing layer technology, applied in the field of polishing layer, can solve the problems of polishing pad hardness, uneven density distribution, uneven distribution of polishing pad, resistance to hydrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Isocyanate prepolymer component: Take 35 parts of TDI-100 (2,4-toluene diisocyanate), 60 parts of PlaccelT2205T (polyether ester polyol), 7 parts of DEG (diethylene glycol), react at 75 ° C for 2 hours Afterwards, the reactants were subjected to vacuum defoaming treatment to obtain prepolymer A1 with an NCO% of 8.0%.

[0053]Weigh 3g functional filler (expanded polymer hollow microspheres) 551DE40d42 and add it to the above-mentioned 100g isocyanate prepolymer A1, then add 43g curing agent Duracure C3LF, the stoichiometric ratio of NH2:NCO is 90%, at a mixing temperature of 55°C 1. Mix the mixture evenly at a rotating speed of 3500r / min, and pour it into a mold at 80°C, gel at room temperature for 15 minutes, then release the mold, and then perform secondary vulcanization at 100°C for 16 hours to obtain the polyurethane polishing layer N1.

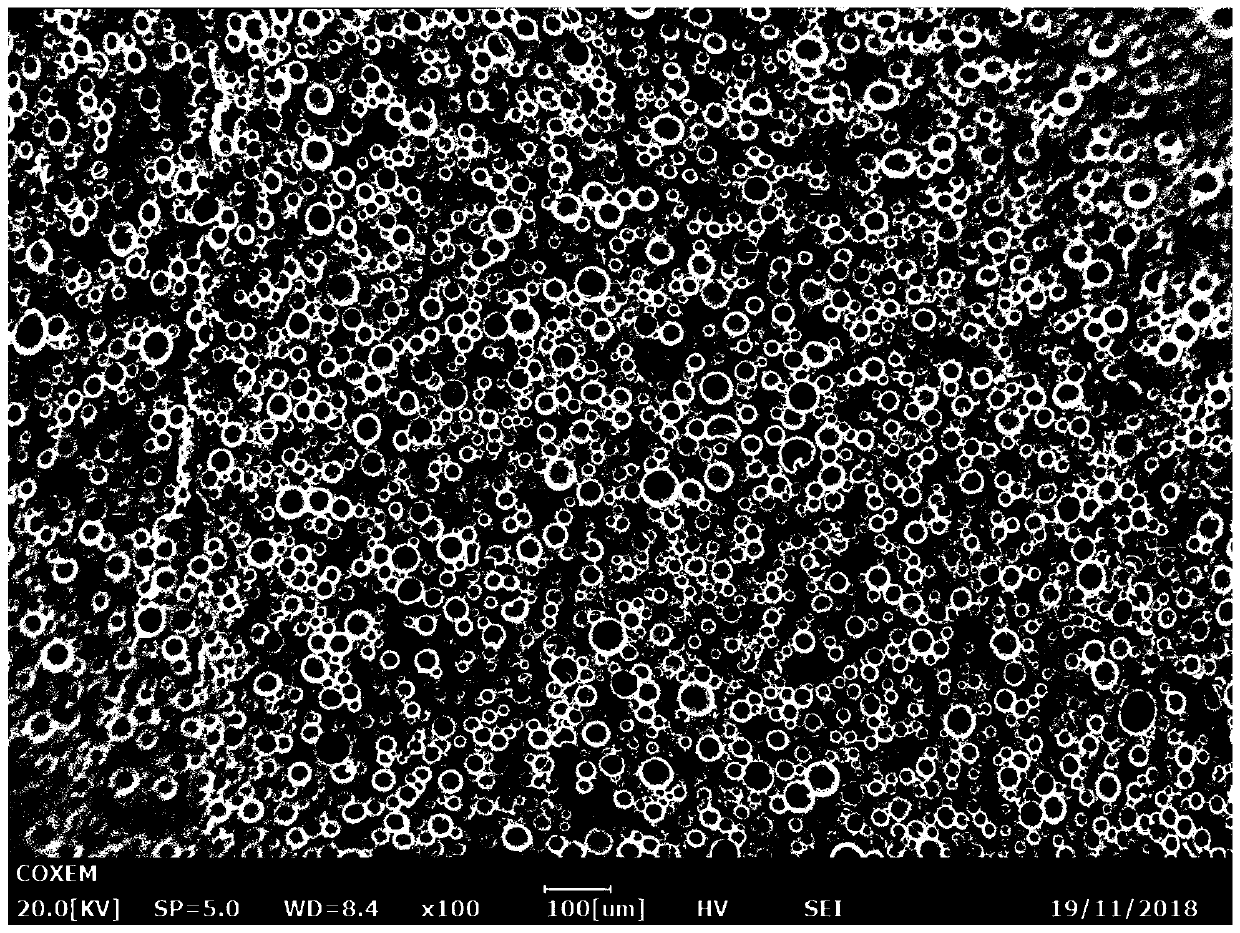

[0054] figure 1 It is the scanning electron micrograph of the polished layer obtained in Example 1. It can be seen from the figu...

Embodiment 2

[0055] Embodiment 2 (compared with embodiment 1, change functional filler)

[0056] Isocyanate prepolymer component: Take 35 parts of TDI-100 (2,4-toluene diisocyanate), 60 parts of PlaccelT2205T (polyether ester polyol), 7 parts of DEG (diethylene glycol), react at 75 ° C for 2 hours Afterwards, the reactants were subjected to vacuum defoaming treatment to obtain prepolymer A1 with an NCO% of 8.0%.

[0057] Weigh 1.8g functional filler (expanded polymer hollow microspheres) 461DET40d25 and add it to the above-mentioned 100g isocyanate prepolymer A1, then add 43g curing agent Duracure C3LF, NH2: The stoichiometric ratio of NCO is 90%, at a mixing temperature of 55 Mix the mixture evenly at 3500r / min at a speed of 3500°C, and pour it into a mold at 80°C, gel at room temperature for 15 minutes and demould, and then perform secondary vulcanization at 100°C for 16 hours to obtain a polyurethane polishing layer N2.

Embodiment 3

[0059] Isocyanate prepolymer component: Take 35 parts of TDI-100 (2,4-toluene diisocyanate), 50 parts of PlaccelT2205T (polyether ester polyol), 8 parts of DEG (diethylene glycol), react at 75 ° C for 2 hours Afterwards, the reactants were subjected to vacuum defoaming treatment to obtain prepolymer A2 with an NCO% of 9.0%.

[0060] Weigh 3.7g functional filler (expanded polymer hollow microspheres) 551DE40d42 and add it to the above-mentioned 100g isocyanate prepolymer A2, then add 48g curing agent Duracure C3LF, NH2: The stoichiometric ratio of NCO is 90%, at a mixing temperature of 55 Mix the mixture evenly at 3500r / min at a speed of 3500°C, and pour it into a mold at 80°C, gel at room temperature for 15 minutes and demould, and then perform secondary vulcanization at 100°C for 16 hours to obtain the polyurethane polishing layer N3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com