Polishing solution for A orientation sapphire polishing, and preparation method thereof

A polishing liquid and sapphire technology, applied in the field of sapphire polishing, can solve the problems of excessive loss of auxiliary materials, high wafer surface roughness, and low polishing efficiency, and achieve the effects of saving production costs, improving polishing efficiency and polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Formula (percentage by weight):

[0026] 92-97 parts of silica sol, 0.01-1 part of active dispersant, 0.01-1 part of wetting agent, 0.01-2 parts of polishing aid, 0.01-1 part of oxidizing agent, 0.01-2 parts of pH regulator, and the balance for deionized water.

[0027] During preparation, it is completed by the following process steps:

[0028] A. Use a 500-mesh screen filter system to remove impurity particles in the silica sol raw material;

[0029] B. Stir the above-mentioned filtered 35-55 wt% silica sol at a speed of 60-120 rpm, and then add active dispersant, wetting agent and polishing aid at a flow rate of 0.5-2.0 L / min;

[0030] C. Continue to add the oxidizing agent and the pH regulator at a flow rate of 0.5-2.0 L / min, and adjust the pH value to 9.5-11, and obtain the finished polishing solution after purification.

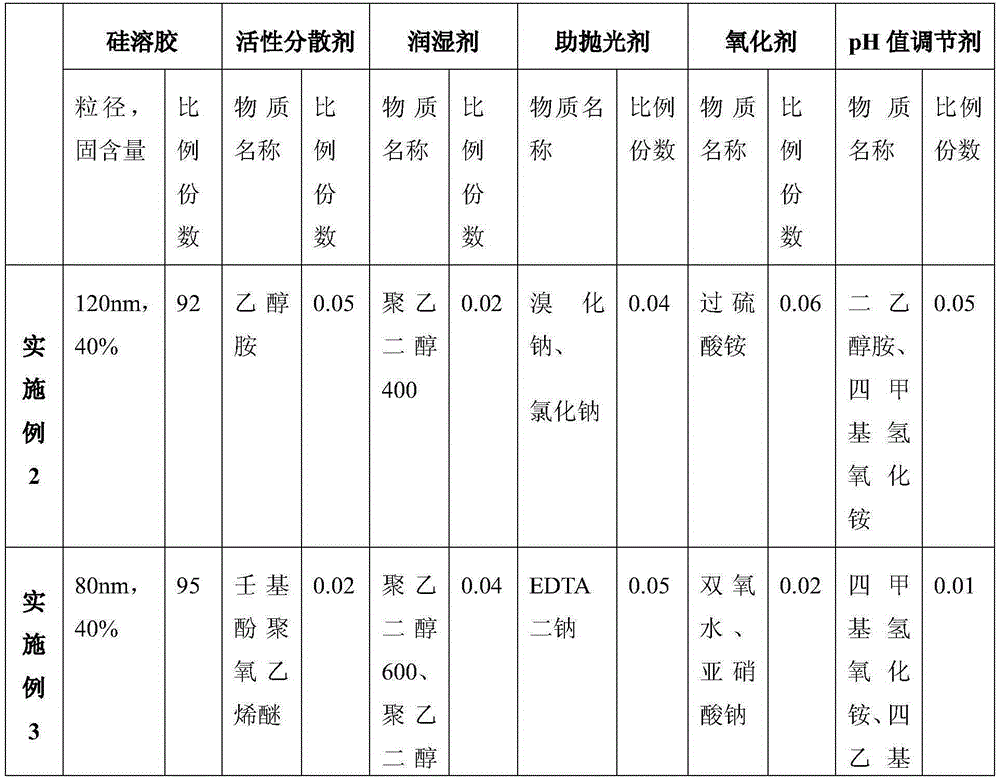

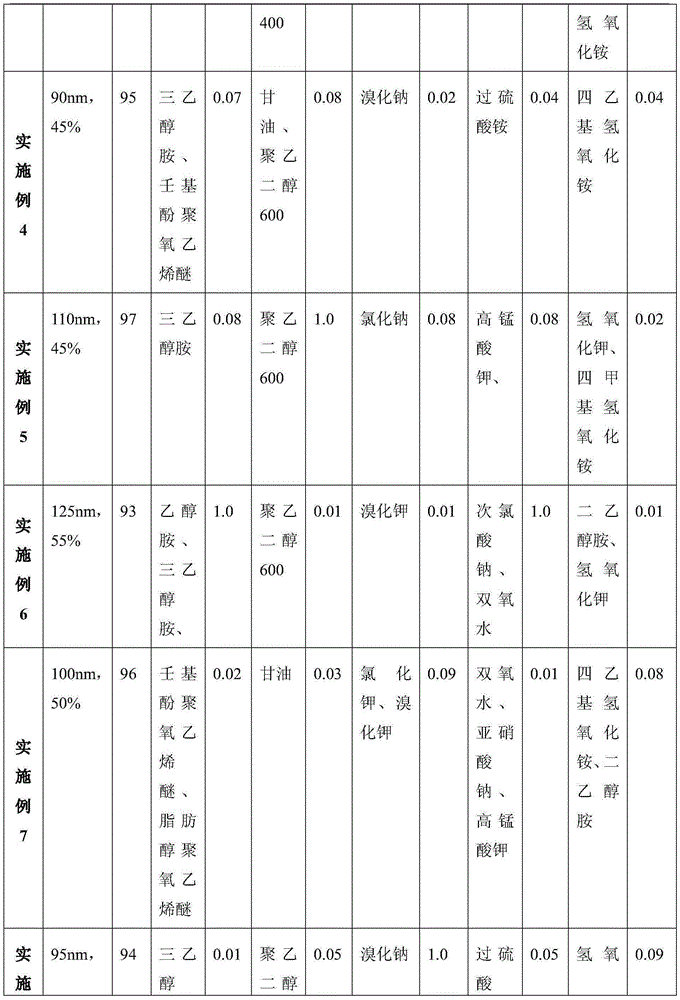

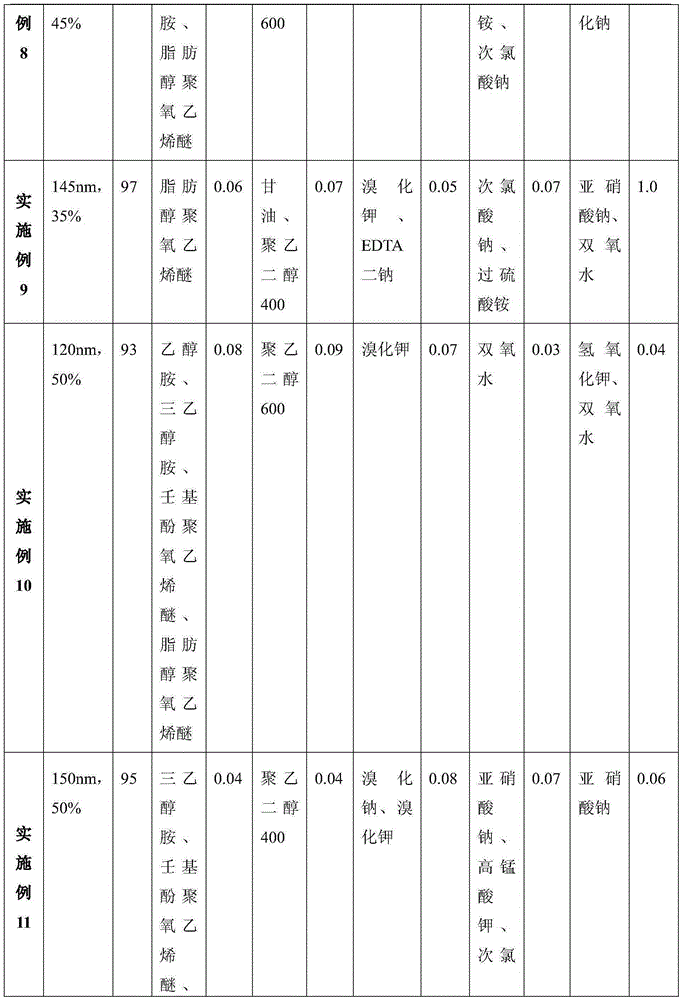

[0031] The following examples adopt the same preparation method as Example 1, and the specific substances and weight percentages used in its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com