Magnetorheological polishing device and method

A technology of magnetorheological polishing and magnetorheological fluid, which is applied in the field of polishing equipment and technology, can solve the problems of poor uniformity of microscopic texture on the polished surface, affect the quality of polishing, and poor adaptability, so as to improve the uniformity of microscopic texture , Improve the polishing quality and remove the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

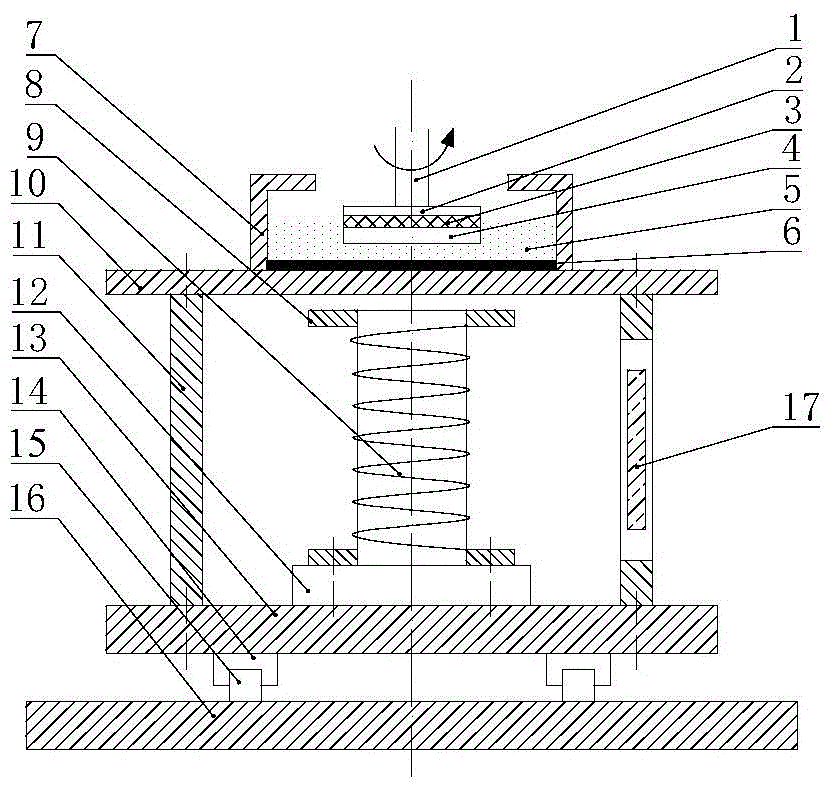

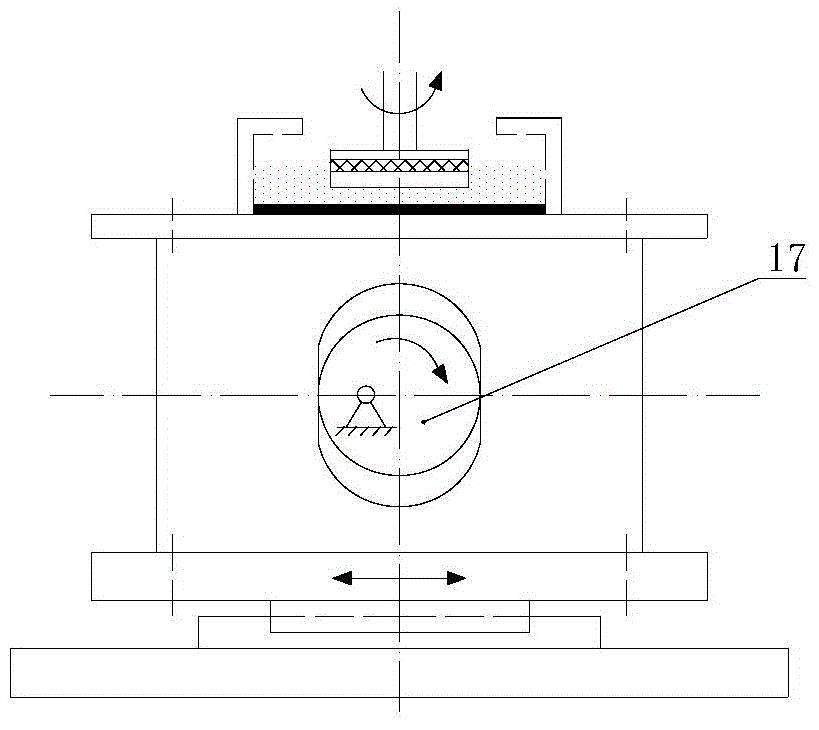

[0036] In this embodiment, the above-mentioned magnetorheological polishing device is used to polish the surface of K9 optical glass (hereinafter referred to as the workpiece) whose length and width are 100 mm × 60 mm and the pre-processed surface roughness Ra = 67 nm. The following steps are carried out:

[0037] (1) Install the workpiece under the non-magnetic fixture, adjust the upper and lower positions of the platform, so that the workpiece is immersed in the magnetorheological fluid in the liquid-carrying tank; adjust the thickness of the non-magnetic backing plate to make the distance between the electromagnet and the workpiece 15mm;

[0038] (2) Turn on the driving motor of the workpiece shaft, so that the workpiece shaft drives the soft magnetic plate, the non-magnetic fixture and the workpiece to rotate synchronously;

[0039] (3) Adjust the electromagnet coil current to DC 3A so that the magnetic flux density of the electromagnet is 0.25T;

[0040] (4) Adjust the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com