Full-automatic diamond abrading and polishing machine

A fully automatic, stone grinding technology, applied in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, grinding machines, etc., can solve problems that affect product use, low work efficiency, and complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

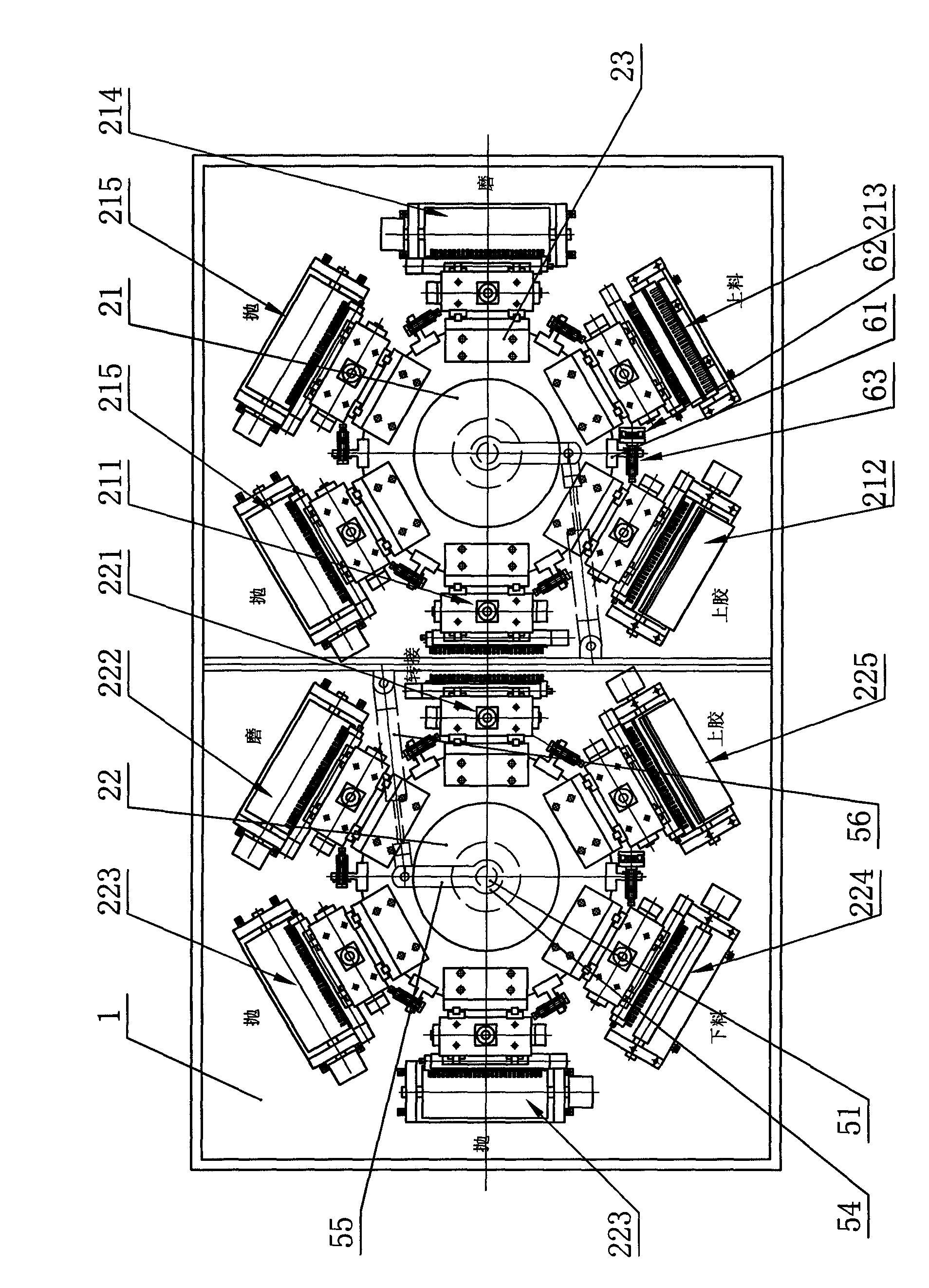

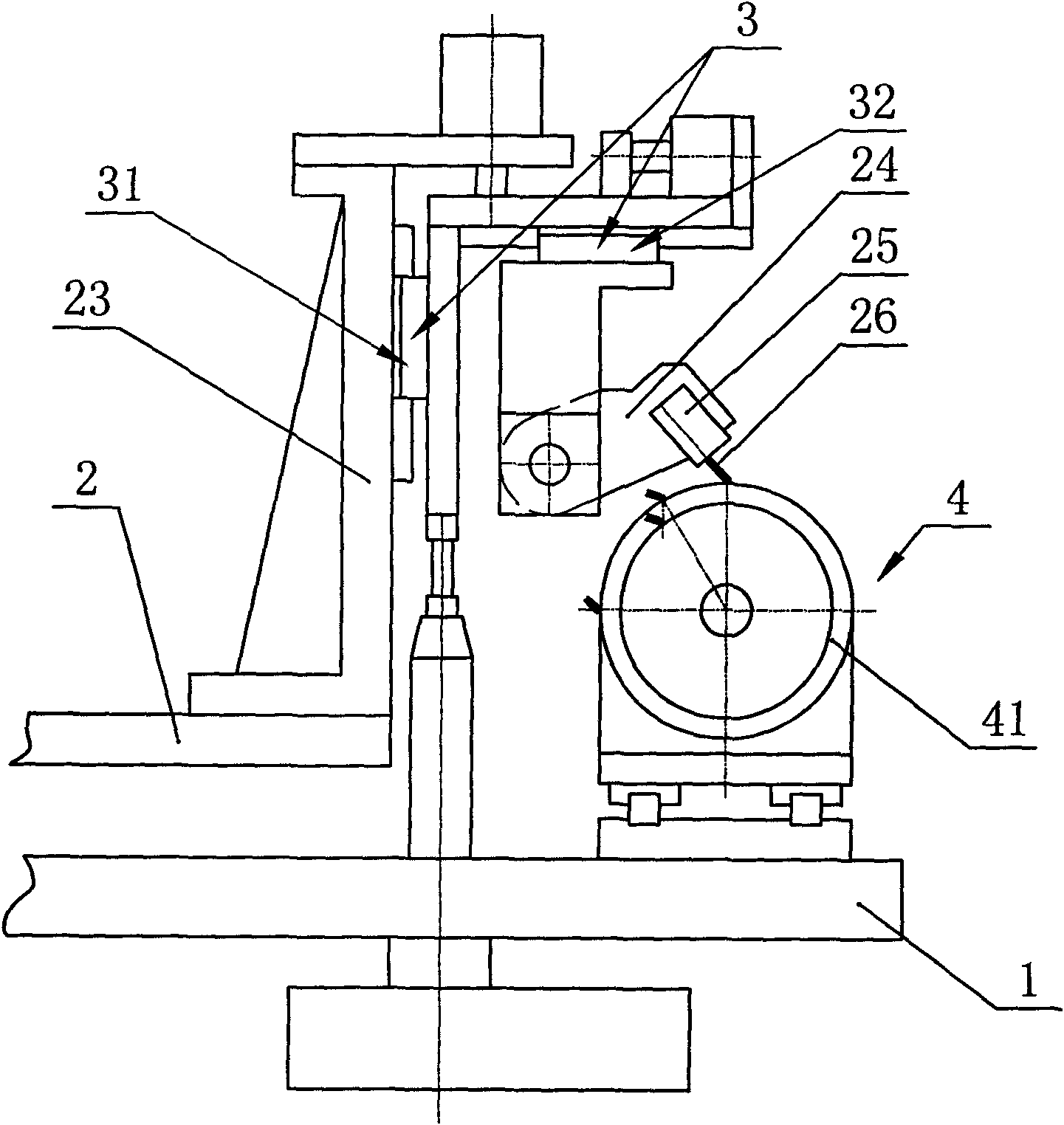

[0023] Such as figure 1 , 2 The specific embodiment 1 of the present invention shown in , 4, 5, 6, and 7 includes a frame 1 and a turntable 2, and the turntable 2 includes two seats, which are respectively a first turntable 21 and a second turntable 22, It also includes a turntable rotation mechanism. The two turntables 2 are arranged to rotate synchronously and in the same direction through the turntable rotation mechanism. The first turntable 21 is provided with transfer stations 211 and upper The glue station 212, the blank station 213, the grinding station 214 and at least one polishing station 215, the second turntable 22 is arranged on the side of the first turntable 21, and the second turntable 22 turns and The switching station 221, the grinding station 222, at least one polishing station 223, the blanking station 224, the gluing station 225 whose interval is equal to the interval between the adjacent stations of the first turntable 21, and the two turntables The tra...

specific Embodiment approach 2

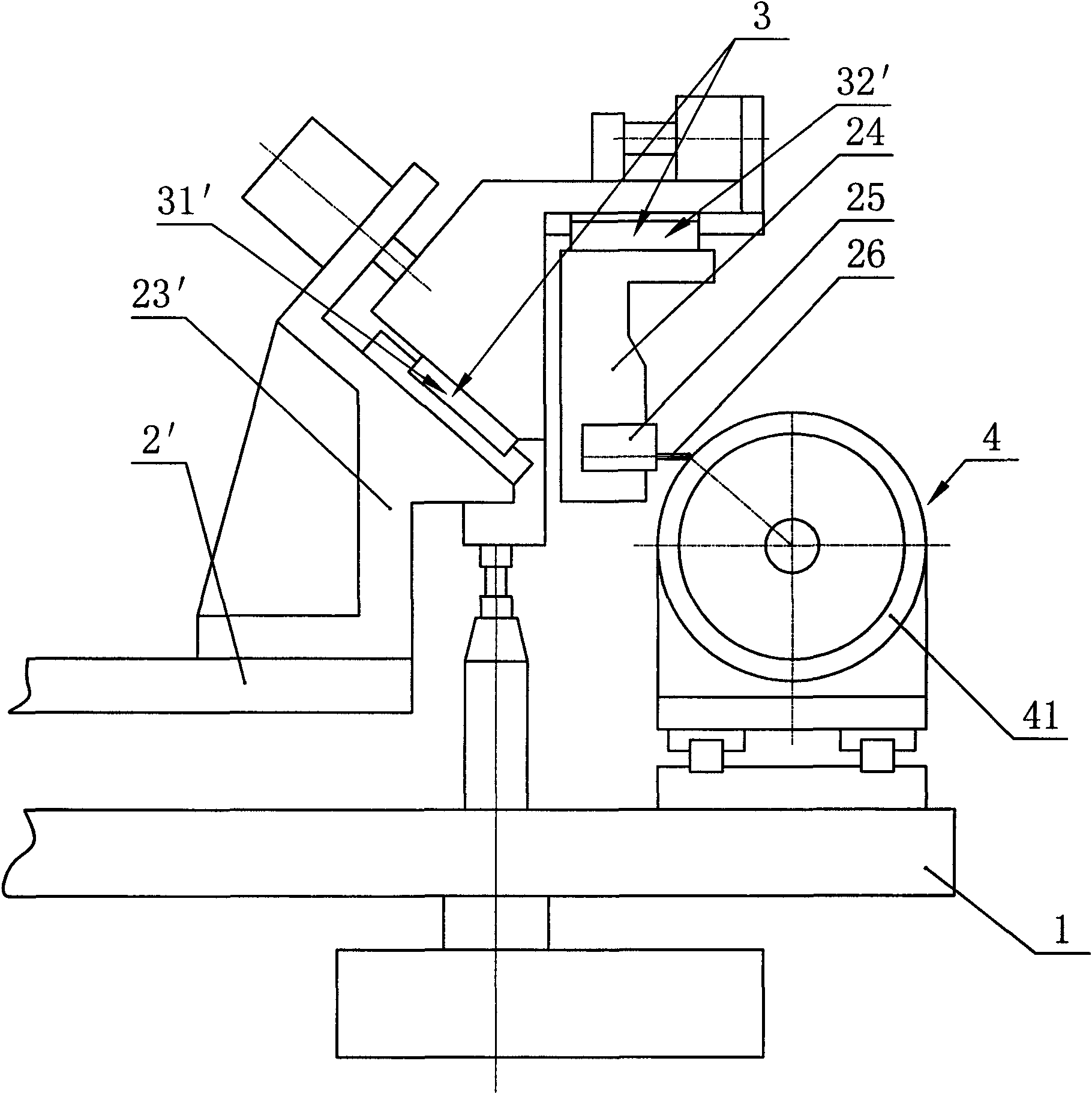

[0031] Such as figure 1 , 3 , 4, 5, 6, 7, and 8 show the specific embodiment 2 of the present invention. The difference between this embodiment 2 and embodiment 1 is that the described grinding and polishing mechanism includes a clamp movement adjustment device 3 and a grinding The throwing wheel device 4, the said frame 23 is an obliquely pushed frame 23', and the described fixture movement adjusting device 3 includes a diagonally moving device 31' and a laterally moving device 32', the obliquely moving device and laterally moving The device can be realized by using a cylinder with an inclined line rail or a horizontal line rail. The grinding and polishing wheel 41 of the grinding and polishing wheel device 4 is a drum type grinding and polishing wheel, and the blank on the clamp 25 is adjusted with the movement of the clamp. The control of the device 4 forms the grinding and polishing cooperation with the drum type grinding and polishing wheel 41 . In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com