Lignin removing pulping agent and plant fiber lignin removing pulping method

A plant fiber and lignin technology, applied in the field of plant fiber pulping, can solve the problems of high efficiency and high quality of the paper industry, and slow lignin action, so as to shorten the pulping cycle, reduce lignin residues, and speed up The effect of removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

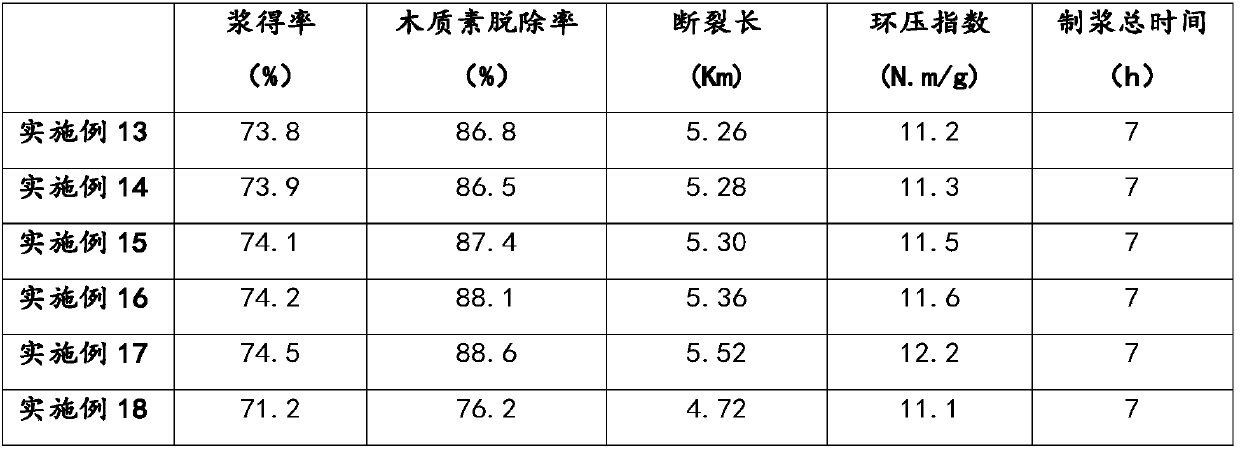

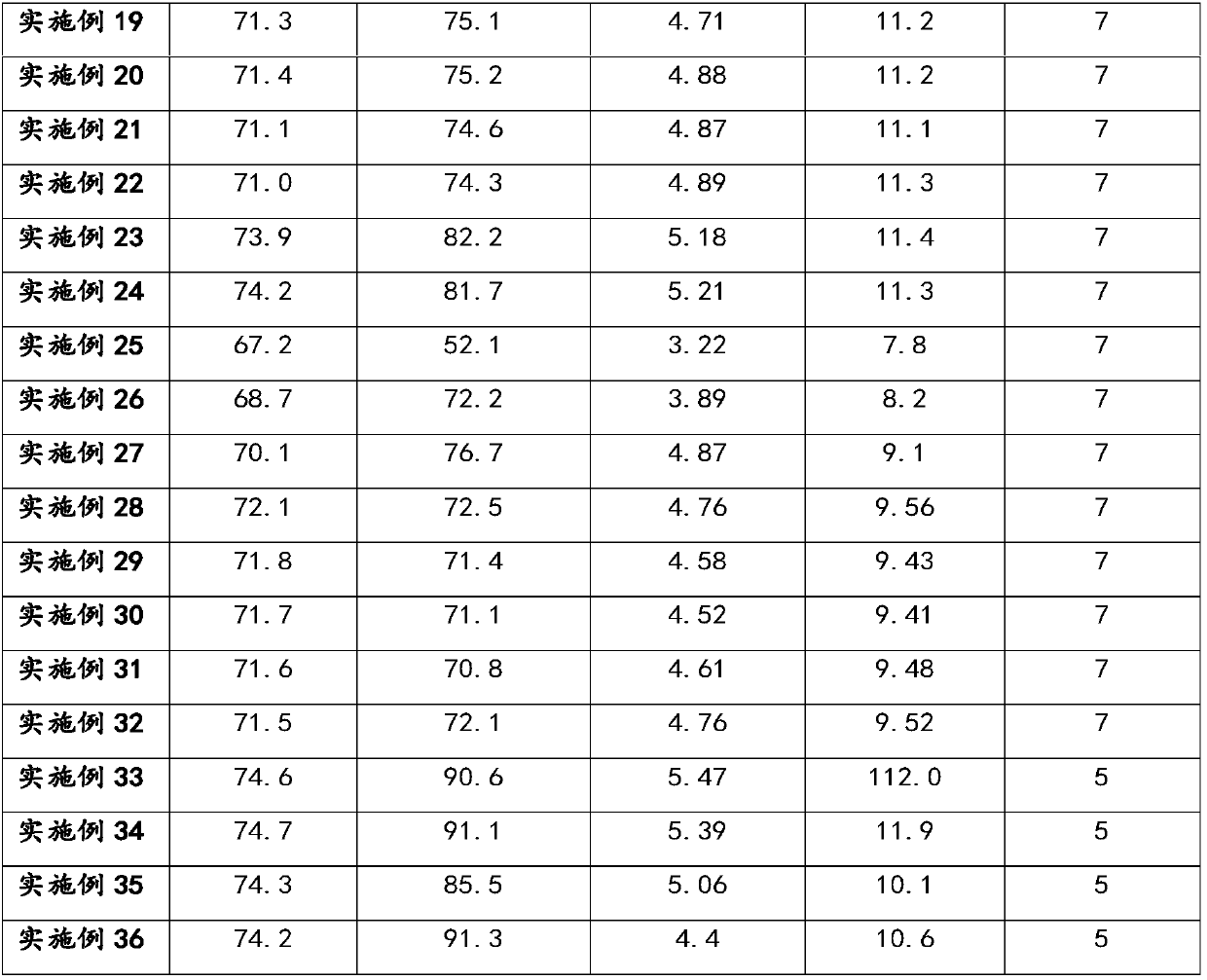

Examples

Embodiment 1

[0066] The present embodiment provides a kind of lignin removal agent, comprises composite biological enzyme agent, composite microbial bacterial agent and chemical auxiliary agent, and the mass ratio of the three is 4:3:3, and wherein composite biological bacterial agent comprises laccase, Composed of ligninase, hemicellulase, xylanase, glucosidase, lipoxygenase and coenzyme, and the mass ratio of the seven is: 5:2:1:1:1:1:2; compound microorganism The bacterial agent is composed of white rot fungi, ascomycetes, Trichoderma konii and Trichoderma viride, and the mass ratio of the four is 3:3:2:2; the chemical auxiliary agent is composed of diammonium phosphate, polyoxyethylene sorbitan mono-oil acid ester, sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether, and the mass ratio of the four is 5:5:2:1.

Embodiment 2

[0068] The present embodiment provides a kind of lignin removing agent, comprises composite biological enzyme agent, composite microbial bacterial agent and chemical auxiliary agent, and the mass ratio of the three is 3:1:1, and wherein composite biological bacterial agent comprises laccase, Composed of ligninase, hemicellulase, xylanase, glucosidase, lipoxygenase and coenzyme, and the mass ratio of the seven is: 3:2:2:2:2:2:1; composite microorganism The bacterial agent is composed of white rot fungi, ascomycetes, Trichoderma konii and Trichoderma viride, and the mass ratio of the four is 1:1:1:1; the chemical auxiliary is composed of diammonium phosphate, polyoxyethylene sorbitan mono-oil acid ester, sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether, and the mass ratio of the four is 1:1:1:1.

Embodiment 3

[0070] The present embodiment provides a kind of lignin removing agent, comprises composite biological enzyme agent, composite microbial bacterial agent and chemical auxiliary agent, and the mass ratio of the three is 2:1:1, and wherein composite biological bacterial agent comprises laccase, Composed of ligninase, hemicellulase, xylanase, glucosidase, lipoxygenase and coenzyme, and the mass ratio of the seven is: 3:3:2:2:2:2:2; compound microorganism The bacterial agent is composed of white rot fungus, ascomycete, Trichoderma konii and Trichoderma viride, and the mass ratio of the four is 3:2:2:2; the chemical auxiliary agent is composed of diammonium phosphate, polyoxyethylene sorbitan mono-oil acid ester, sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether, and the mass ratio of the four is 3:3:2:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com