Water-in-oil microemulsion printing ink cleaning agent and preparation method thereof

A water-in-oil type, microemulsion technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of high water content, slow volatilization and drying of cleaning agents, unfavorable drying of printing machine parts, etc., and achieve penetration ability Strong, excellent cleaning power, fast diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

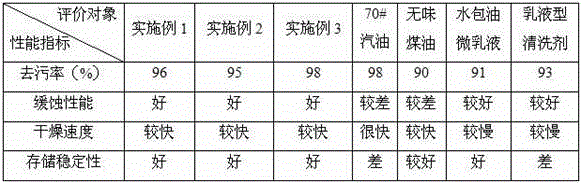

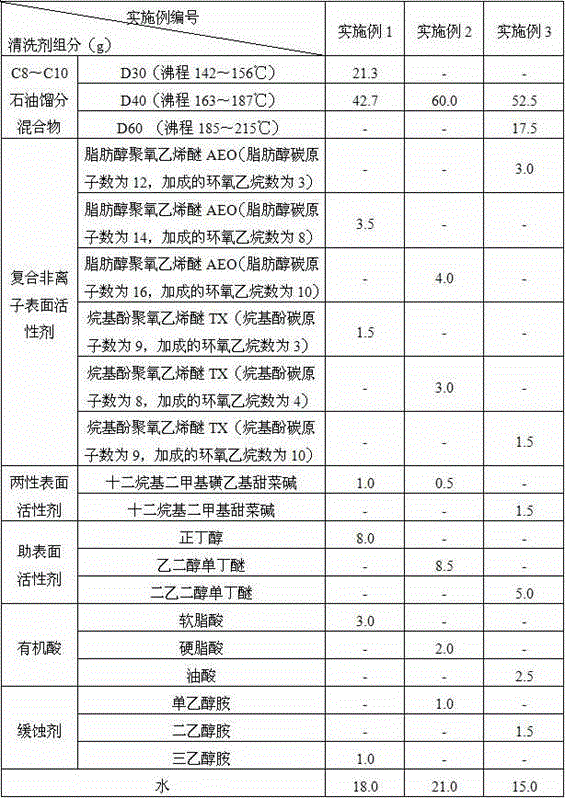

[0034] Water-in-oil type microemulsion ink cleaning agent embodiment 1~3

[0035] Examples 1-3 The components and contents of the water-in-oil microemulsion ink cleaning agent are shown in Table 1.

[0036] Table 1 The components and contents of the water-in-oil microemulsion ink cleaning agent of Examples 1-3

[0037]

[0038] Note: "-" in the table means not added.

[0039] The preparation method embodiment 1~3 of water-in-oil type microemulsion ink cleaning agent

[0040] According to the components and their contents of Examples 1 to 3 in Table 1, at room temperature, first add the C8 to C10 petroleum fraction mixture into the reaction kettle, and under stirring, add the composite nonionic surfactant, amphoteric surfactant agent and co-surfactant, after stirring for 30 minutes, then add the mixture of pre-mixed organic acid and corrosion inhibitor, and finally add water, and stir for 30 minutes until the mixed solution becomes clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com