Solid amine adsorbent, preparation method thereof, and CO2 adsorption assembly containing same

A technology of adsorbent and solid amine, which is applied in the field of gas purification, can solve the problems of reducing the porosity of macroporous materials, low density of carbon nanotubes, and affecting the adsorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

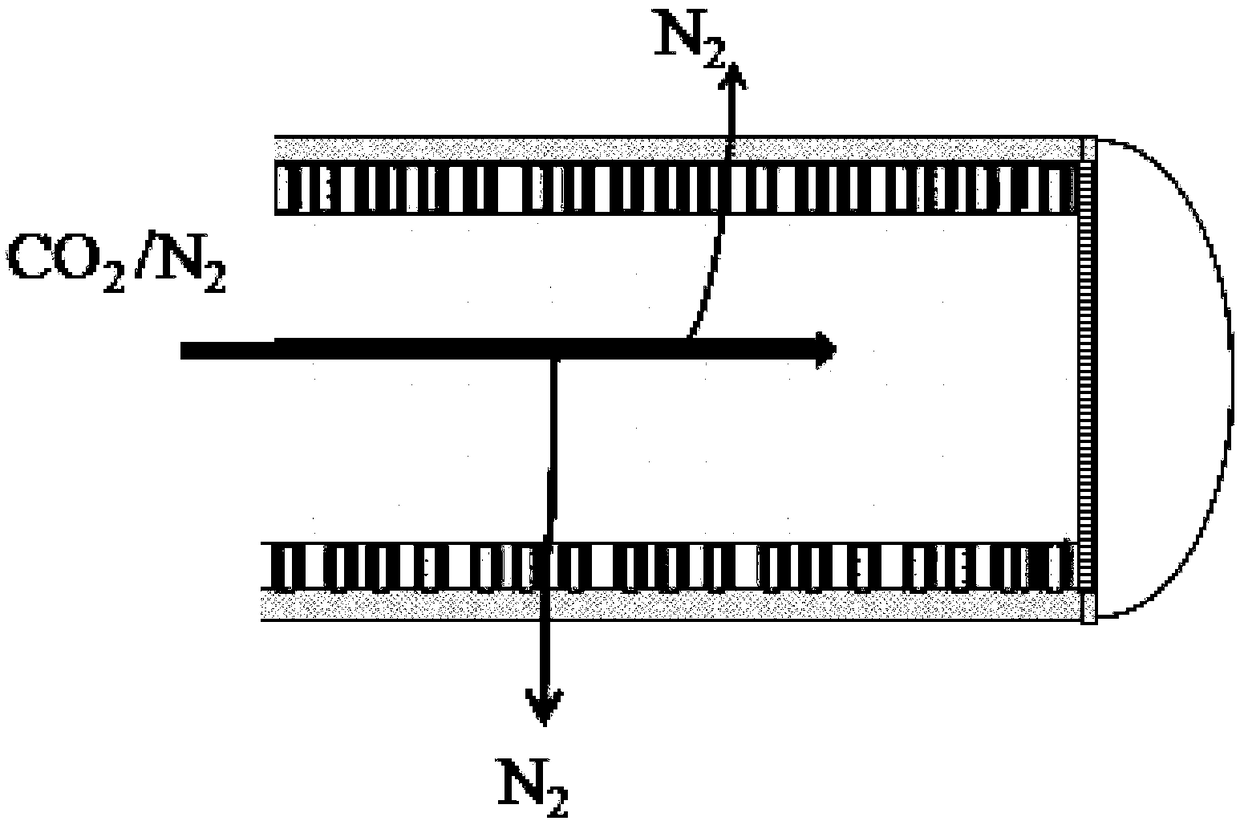

[0051] a CO 2 Adsorption components, the preparation method is as follows:

[0052] (1) Preparation of polysulfone (PSF) hollow fiber: PSF, N-methyl-2-pyrrolidone (NMP), and diethylene glycol (DEG) are PSF:NMP:DEG=1:4 in weight ratio : The ratio of 1.25 is fully stirred to obtain a uniform and stable solution. The solution was degassed in a 0.2MPa vacuum box for 1h, and then moved to the spinning equipment tank. Under the nitrogen pressure of 0.3MPa, the mixed solution of 99% NMP and 1% ethanol was used as the core fluid, deionized water was used as the external coagulant, and the air gap was 2cm for spinning. After fully curing, PSF hollow fibers were obtained.

[0053] (2) Prepare an ethanol solution containing 25% tetraethylenepentamine (TEPA) in mass percentage concentration, immerse three 15cm-long hollow fibers in the solution and keep at room temperature for 5 hours, then dry the ethanol with hot air at 50°C for 1 hour to obtain Solid amine adsorbent;

[0054] (3) T...

Embodiment 2

[0057] The only difference with embodiment 1 is that in this embodiment, step (1) and step (2) are as follows:

[0058] (1) Preparation of yttrium-stabilized zirconia (YSZ) hollow fiber: fully stir PSF, NMP, and YSZ at a weight ratio of PSF:NMP:YSZ=1:4:5.2 to obtain a uniform and stable solution. The solution was degassed in a 0.2MPa vacuum box for 1h, and then moved to the spinning equipment tank. Under 0.3MPa nitrogen pressure, use a mixed solution of 99% NMP and 1% ethanol as the core liquid, and use deionized water as the external coagulant for spinning. After fully solidified, the YSZ hollow fiber precursor is obtained. Sintered for 4h to get YSZ hollow fiber.

[0059] (2) Prepare an ethanol solution containing 20% tetraethylenepentamine (TEPA) in mass percent concentration, immerse three 15 cm long hollow fibers in the solution and keep at room temperature for 5 hours, then dry the ethanol with hot air at 40° C. for 2 hours to obtain Solid amine adsorbent.

Embodiment 3

[0061] The only difference with embodiment 1 is that in this embodiment, step (1) and step (2) are as follows:

[0062] (1) Preparation of alumina (Al 2 o 3 ) Hollow fiber: PSF, NMP, Al 2 o 3 PSF:NMP:Al by weight ratio 2 o 3 = The ratio of 1:4:4.6 is fully stirred to obtain a uniform and stable solution. The solution was degassed in a 0.2MPa vacuum box for 1h, and then moved to the spinning equipment tank. Under 0.3MPa nitrogen pressure, use a mixed solution of 99% NMP and 1% ethanol as the core fluid, and use deionized water as the external coagulant. After fully curing, Al 2 o 3 Hollow fiber precursor, the precursor was sintered at 1400°C for 4 hours to obtain Al 2 o 3 hollow fiber.

[0063] (2) Prepare a methanol solution containing 30% by mass of γ-aminopropyltriethoxysilane (APTS), immerse three 15cm-long hollow fibers in the solution and keep it at room temperature for 5 hours, dry it with hot air at 60°C for 2 hours to remove methanol, A solid amine adsorbent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com