Treatment and reutilization method of organic and inorganic compound polluted loess leaching liquid

An inorganic composite and eluent technology, which is applied in the fields of adsorption water/sewage treatment, water/sludge/sewage treatment, inorganic chemistry, etc. Pollution and other problems, to achieve excellent removal effect, fast coagulation and hardening, convenient extraction and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

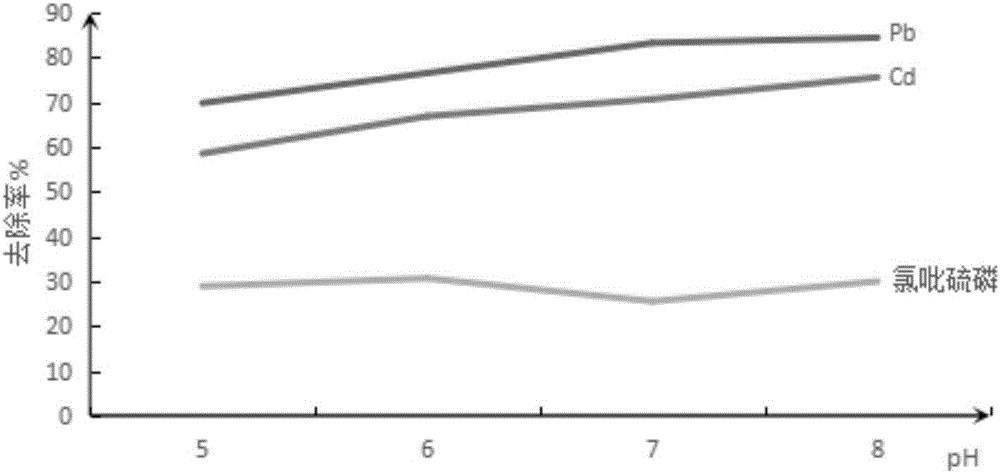

[0053] see figure 1 , at a temperature of 25°C, the concentration ratio of the three pollutants Pb / Cd / pyridion in the eluent is 5 / 5 / 10mL / g, and the eluate and the prepared adsorbent are separated into liquid-solid The ratio is 25 and placed in four 500ml beakers respectively, the pHs are 5, 6, 7, and 8 respectively, and stirring is carried out at a speed of 20-80 rpm to make the adsorbent fully contact with the solution. After it reacted for 4 hours, measure the amount of three kinds of pollutants in four beakers and obtain the removal rate, the obtained data are as follows: figure 1 The removal rates of Pb and Cd showed an upward trend with the increase of pH. When pH=8, the removal rate of Pb was 84.43%, and the removal rate of Cd was 75.59%. The formula fluctuation reaches the maximum at pH=6, which is 30.64, and the adsorption effect is the best when the removal rate is the maximum.

Embodiment 2

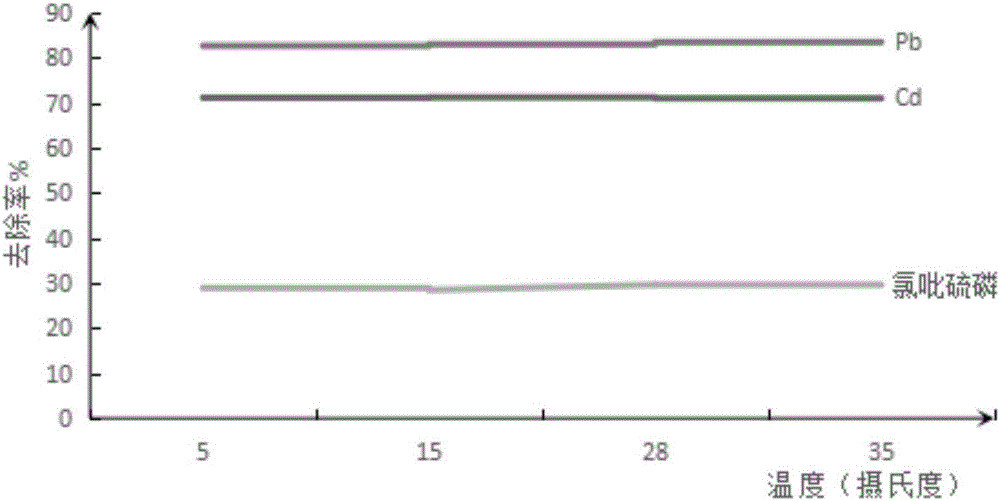

[0055] see figure 2 , the concentration ratio of the three kinds of pollutants Pb / Cd / pyridion in the eluate is 5 / 5 / 10mL / g at pH=7, the concentration ratio of the eluate and the adsorbent made in the liquid-solid ratio Place 25 in four 500ml beakers respectively, heat the four beakers in a water bath at 5°C, 15°C, 25°C, and 35°C, and stir at a rate of 20-80rpm to make the adsorbent fully contact with the solution. After it reacted for 4 hours, measure the amount of three kinds of pollutants in four beakers and obtain the removal rate, the obtained data are as follows: figure 2 As the temperature rises, the removal rate of Pb increases but the trend tends to be flat. When the temperature is 35°C, the removal rate of Pb reaches a maximum of 83.59%. The removal rate of Cd decreases slightly with the increase of temperature and reaches 15°C The maximum is 71.25%. The removal rate of pyrithione increases slowly with the increase of temperature. The maximum removal rate is 30.01% ...

Embodiment 3

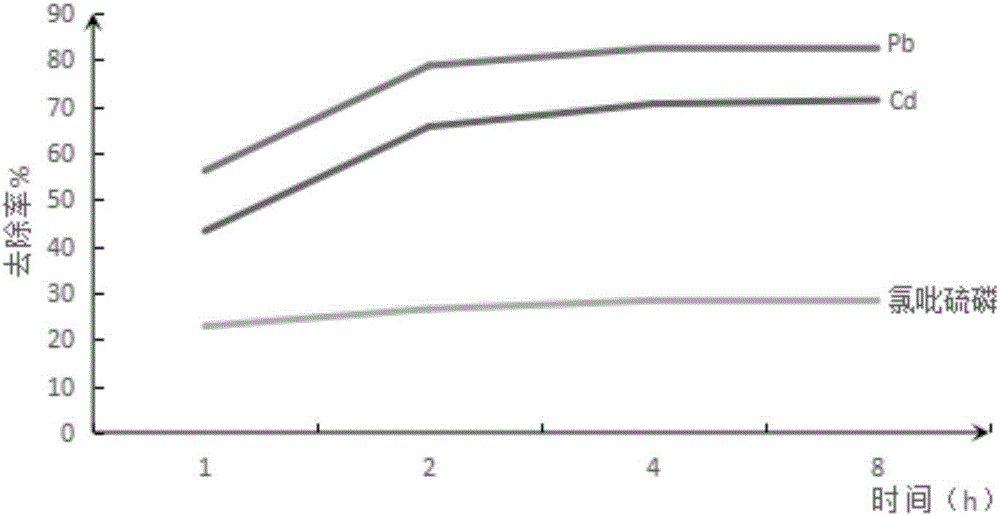

[0057] see image 3 , at a temperature of 25°C, pH=7, and the concentration ratio of the three pollutants Pb / Cd / pyridion in the eluate being 5 / 5 / 10mL / g, the eluent and the prepared adsorption The agent was placed in four 500ml beakers with a liquid-solid ratio of 25, and stirred at a speed of 20-80rpm so that the adsorbent fully contacted with the solution. After 1h, 2h, 4h, and 8h, respectively, measure the amount of pollutants in the eluent after adsorption and obtain the removal rate, such as image 3 It is shown that with the increase of time, the Pb removal rate increases greatly between 1h and 2h, the upward trend of the curve between 2h and 4h is slightly slow, and the trend between 4h and 8h is flat and basically unchanged. The removal rate reached a maximum of 82.68% at 8h; the Cd removal rate increased with the increase of time, and the Cd removal rate increased greatly between 1h and 2h, and the upward trend of the curve between 2h and 8h was slightly slow, reachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com