Compound chemical leaching method for efficient remediation of heavy metal contaminated soil

A contaminated soil and chemical leaching technology, applied in the field of soil remediation, can solve the problems of large-scale promotion and application of large treatment costs, difficulty in obtaining large-scale promotion, and easy to produce secondary pollution, etc., to achieve rapid and efficient leaching repair, Wide application value and market promotion prospect, fast removal effect by leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) First, weigh 0.9g of citric acid, 0.3g of glacial acetic acid, 4.1g of ferric chloride and 6.1g of ferric nitrate and add them to 100ml of deionized water, stir and dissolve, and obtain a standby compound eluent for repairing heavy metal-contaminated soil;

[0028] 2) Grinding the soil polluted by heavy metals through a 10-mesh sieve to remove coarse debris in the soil;

[0029] 3) Weigh 2g of the contaminated soil obtained in step 2) into a 100ml centrifuge tube, add 20ml of the compound eluent obtained in step 1) at a solid-to-liquid ratio of 1:10, and place it in a shaker at room temperature for 180r min -1 Shake for 90min, and then use a centrifuge at 2500r·min -1 Centrifuge for 10 minutes to separate the mud and water.

[0030] 4) Filter the waste liquid after rinsing, and then regenerate it with iron-manganese double metal oxide modified porous adsorption material for 15 minutes.

[0031] 5) Other steps remain unchanged, and the soil leaching test is carried ...

Embodiment 2

[0033] 1) First weigh 1.3g of citric acid, 0.5g of glacial acetic acid, 5.4g of ferric chloride and 7.3g of ferric nitrate and add them to 100ml of deionized water, stir and dissolve to obtain a standby compound eluent for repairing heavy metal-contaminated soil;

[0034] 2) Grinding the soil polluted by heavy metals through a 10-mesh sieve to remove coarse debris in the soil;

[0035] 3) Weigh 2g of the contaminated soil obtained in step 2) into a 100ml centrifuge tube, add 30ml of the compound eluent obtained in step 1) at a solid-to-liquid ratio of 1:15, and place it in a shaker at room temperature for 180r min -1 Shake for 150min, then centrifuge at 2500r min -1 Centrifuge for 10 minutes to separate mud and water;

[0036] 4) The waste liquid after rinsing is regenerated through the recycled material.

Embodiment 3

[0038] 1) First weigh 1.7g of citric acid, 0.3g of glacial acetic acid, 6.8g of ferric chloride and 8.2g of ferric nitrate and add them to 100ml of deionized water, stir and dissolve to obtain a standby compound eluent for repairing heavy metal-contaminated soil;

[0039] 2) Grinding the soil polluted by heavy metals through a 10-mesh sieve to remove coarse debris in the soil;

[0040] 3) Weigh 2g of the contaminated soil obtained in step 2) and add it to a 100ml centrifuge tube, add 10ml of the compound eluent obtained in step 1) at a solid-to-liquid ratio of 1:5, and place it in a shaker at room temperature for 180r min -1 Shake for 120min, then centrifuge at 2500r min -1 Centrifuge for 10 minutes to separate mud and water;

[0041] 4) The waste liquid after rinsing is regenerated through the recycled material.

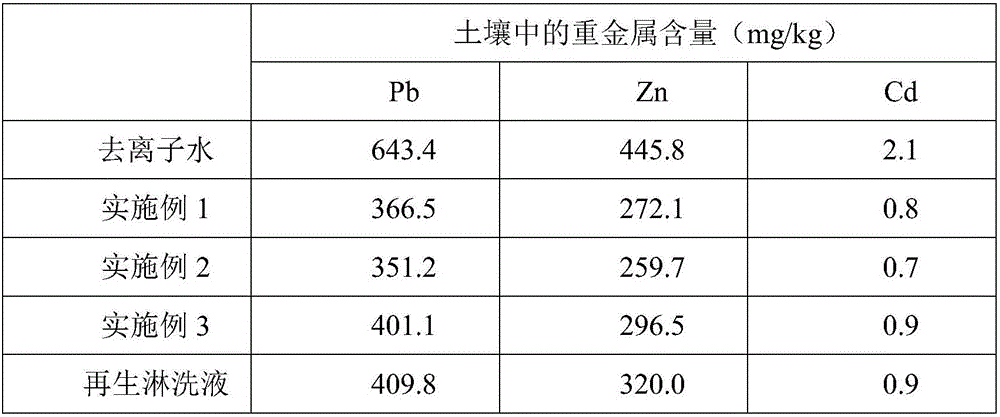

[0042] Table 2 shows the heavy metal content in the soil after the repair treatment of the present invention.

[0043] Table 2 Heavy metal content in soil after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com