Device and method for quickly removing occluded foreign substances in molten steel

A technology for inclusions and molten steel, which is used in the rapid removal device for inclusions in molten steel and in the field of high-quality steel production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

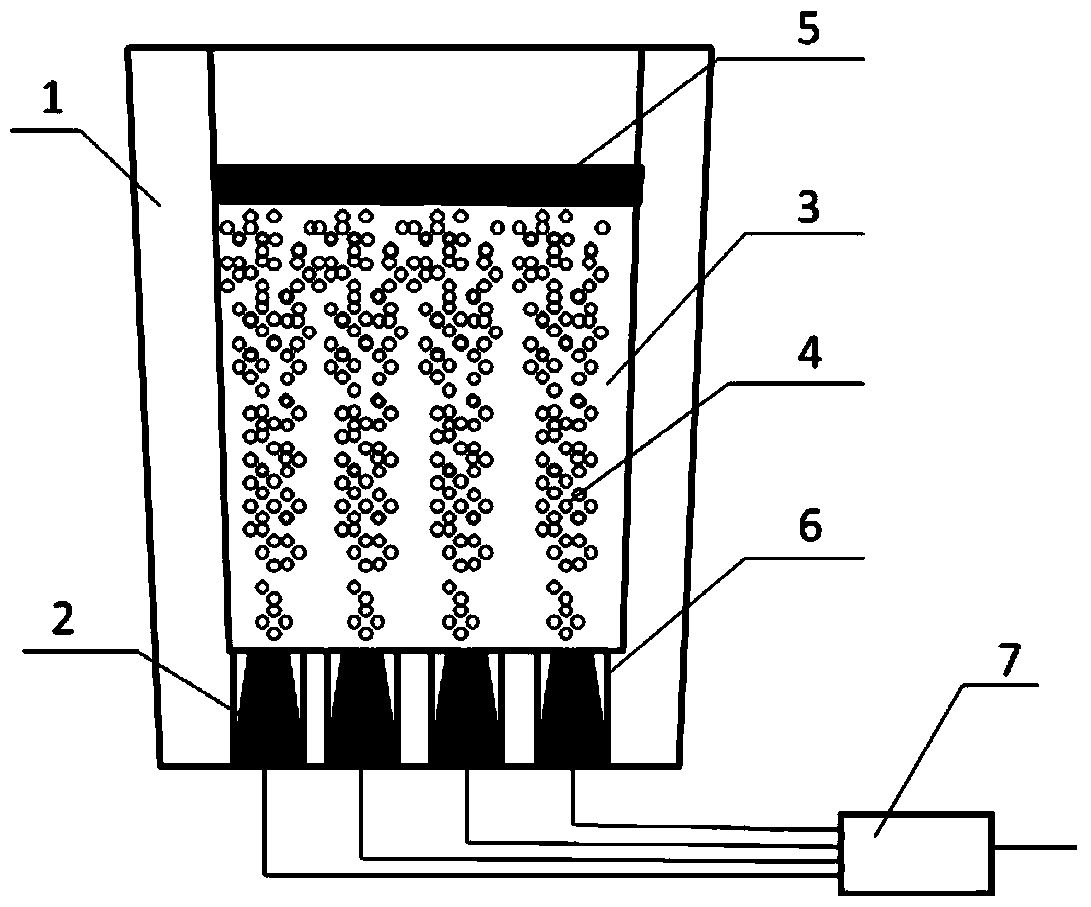

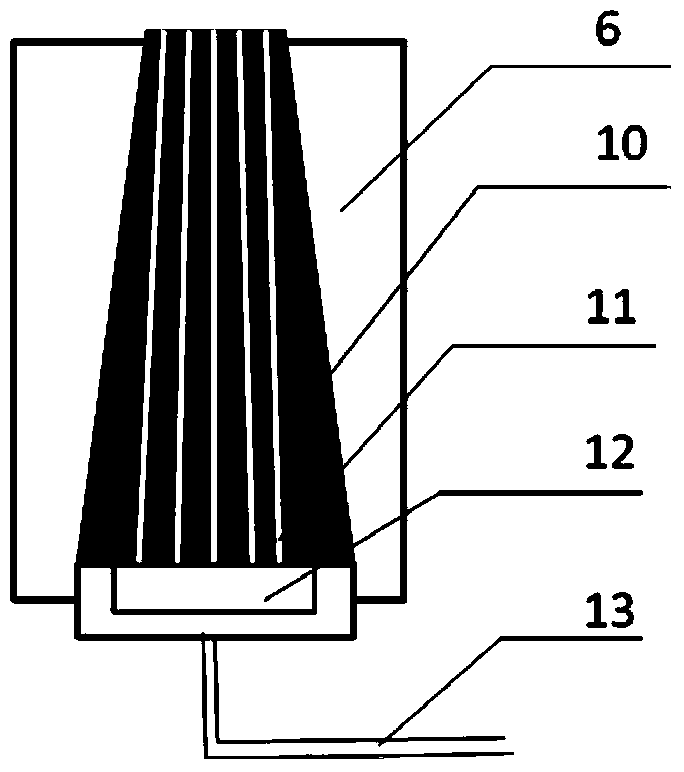

[0017] The device of the present invention includes: a molten steel container 1, a specific gas supply element 2, a protective brick 6, a bottom blowing gas adjustment system 7, and the like. A specific gas supply element 2 is installed at the bottom of the molten steel container 1 to generate a wide range of dispersed microbubbles 4 in the molten steel 3 to be treated by bottom blowing inert gas, and the inclusions are captured to the greatest extent by a large number of microbubbles distributed in the molten steel It promotes its floating to the top slag 5 to be removed to purify the molten steel; a protective brick 6 is installed outside the specific gas supply element 2, and the bottom blowing gas adjustment system 7 is connected to the specific gas supply element 2 through a pipe 13 to control the flow rate of the bottom blowing gas .

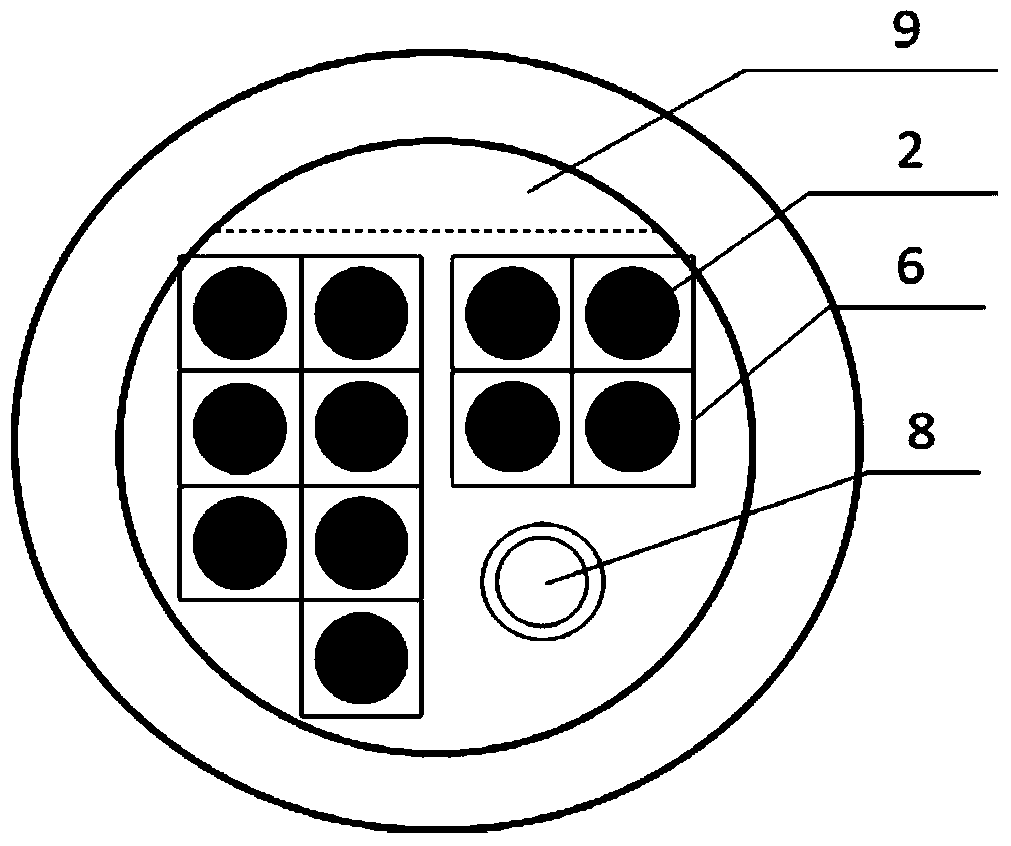

[0018] At the bottom of the ladle, while avoiding the nozzle 8 area and the molten steel impact area 9, 11 special air supply elements 2 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com