Electrogenerated chemical polishing method

An electrochemical and chemical reaction technology, applied in the field of polishing, can solve the problems of difficulty in etching the leveling agent liquid layer, difficulty in replenishing the scavenger, and decreased selective removal ability of materials, etc., and achieves the effect of scientific steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

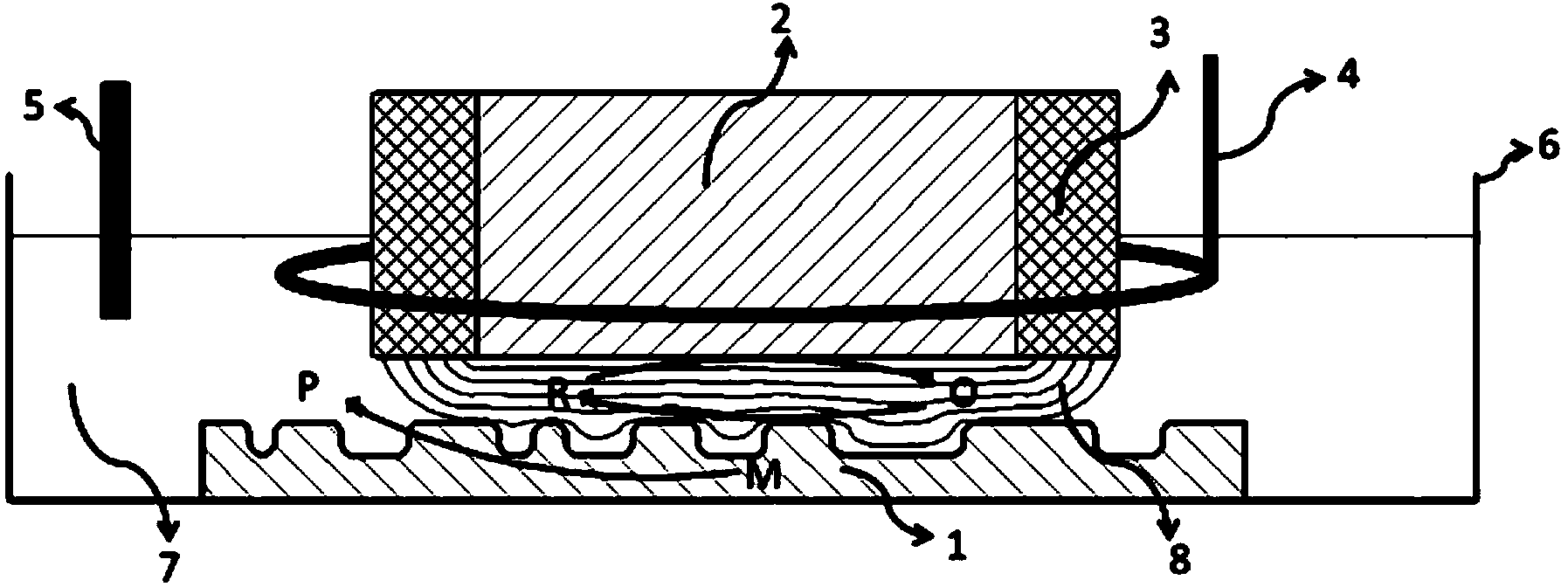

[0039] This embodiment discloses a method of electrochemical polishing, the method adopts the attached figure 1 The reaction device shown, the reaction device includes a container 6, a working electrode 2, a reference electrode 5 and an auxiliary electrode 4, the working electrode 2 is a glassy carbon electrode, the working surface of the working electrode 2 has a flatness of less than 1 μm, and the working electrode 2. The surface except the working surface is covered with an insulating layer 3. The working electrode 2 , the reference electrode 5 and the auxiliary electrode 4 are all arranged directly above the workpiece 1 . In this embodiment, the workpiece 1 to be polished is a copper workpiece.

[0040] The working fluid used in this example contains an electroactive mediator of 0.05mol / L FeSO 4 , pH regulator 0.2mol / L H 2 SO 4 And the inhibitor 1mmol / L BTA (benzotriazole); its temperature is kept at 23±0.5°C during the whole etching and leveling process.

[0041] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com