Patents

Literature

40results about How to "Method steps are reasonable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel faulty line selection method in low current faulty grounding system

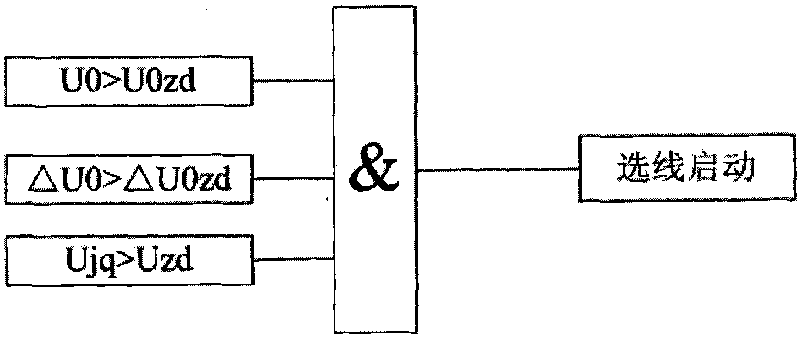

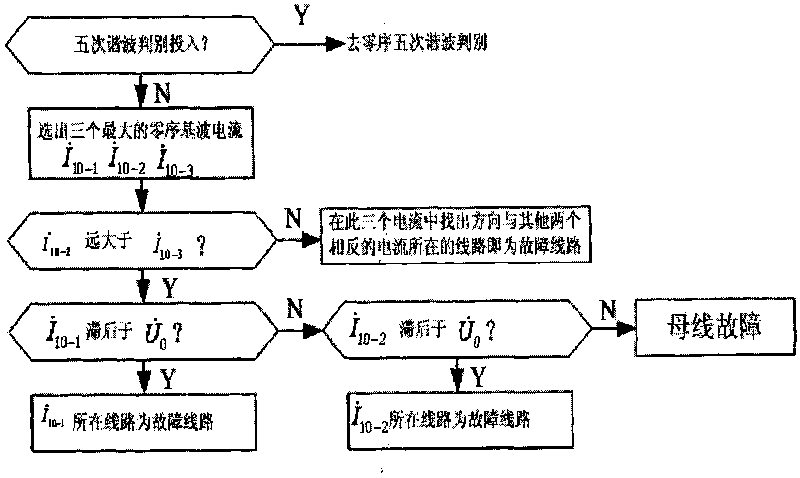

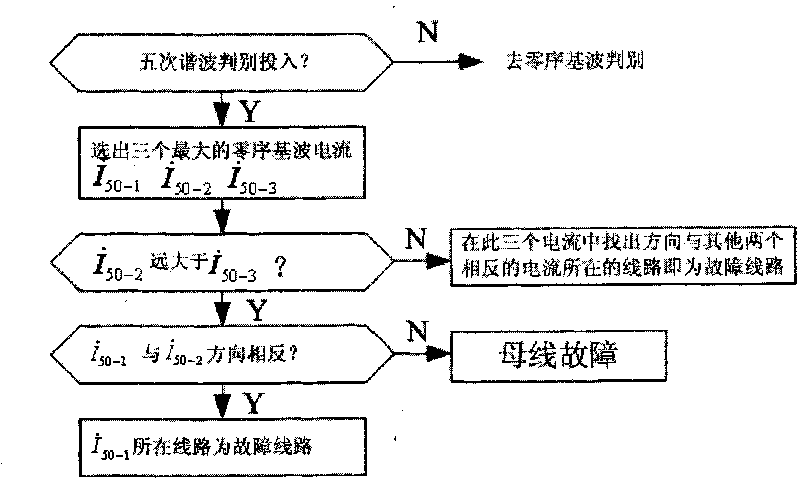

InactiveCN101701998ALine selection is accurateOvercome the problem of low accuracy of fault line selectionEmergency protective circuit arrangementsFault locationHarmonicSelection criterion

The invention discloses a novel faulty line selection method in a low current faulty grounding system, which judges whether a ground fault happens or not by detecting zero sequence voltage and phase voltage of a system bus, determines to judge grounded fault circuit adopting different faulty line selection methods according to the different characteristics of zero sequence fundamental wave and zero sequence quintuple harmonic current generated according to that arc suppression coil exists in a system when single-phase grounding fault happens on the premise that ground fault occurs, combines with some assistant line selection criteria to perform comprehensive judgment so as to select the circuit with a fault correctly, thus overcoming the problem of low accuracy of faulty line selection in a low current grounding system. The invention has the characteristics of reasonable method steps, high accuracy of faulty line selection and convenient operation and application.

Owner:山东泰开自动化有限公司

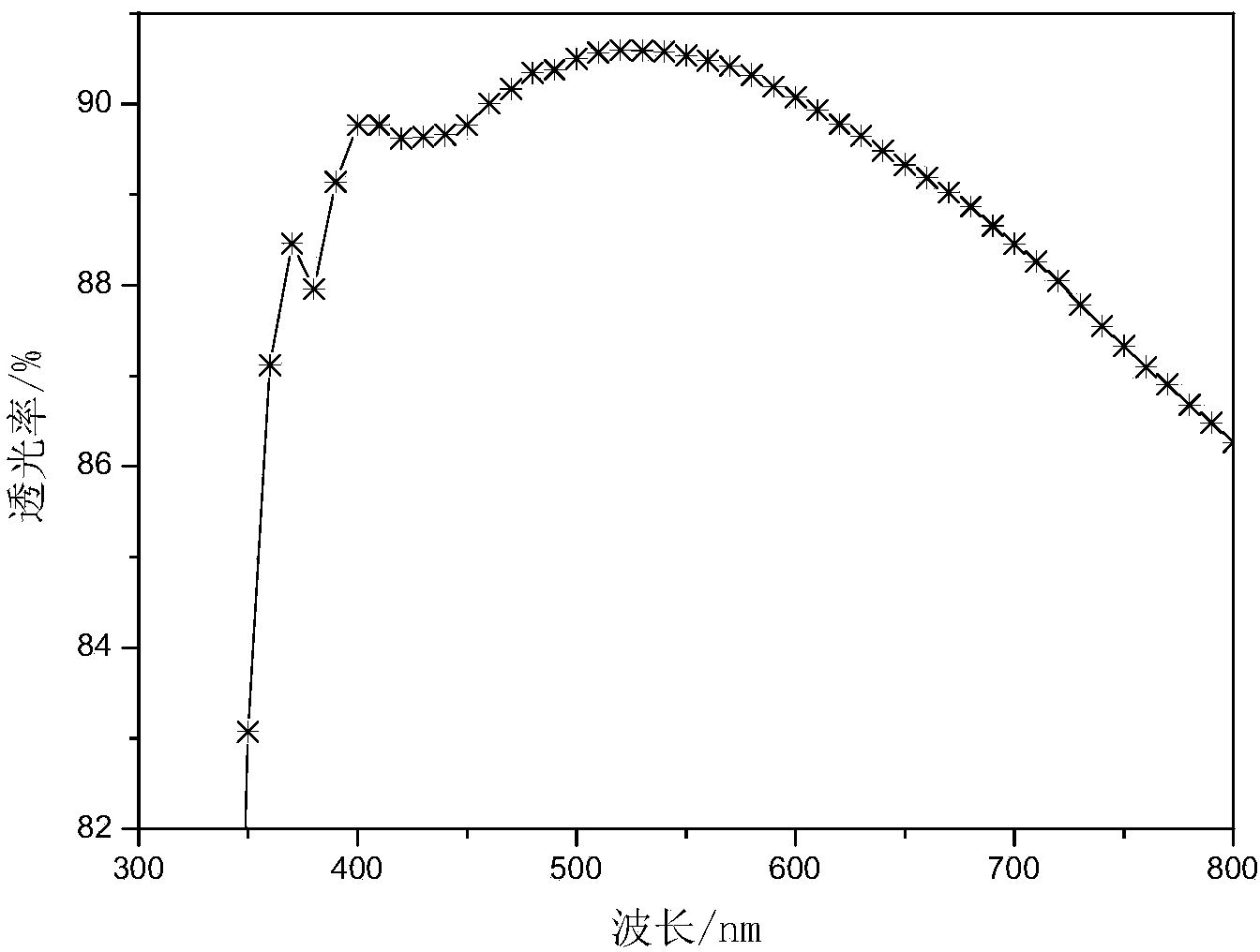

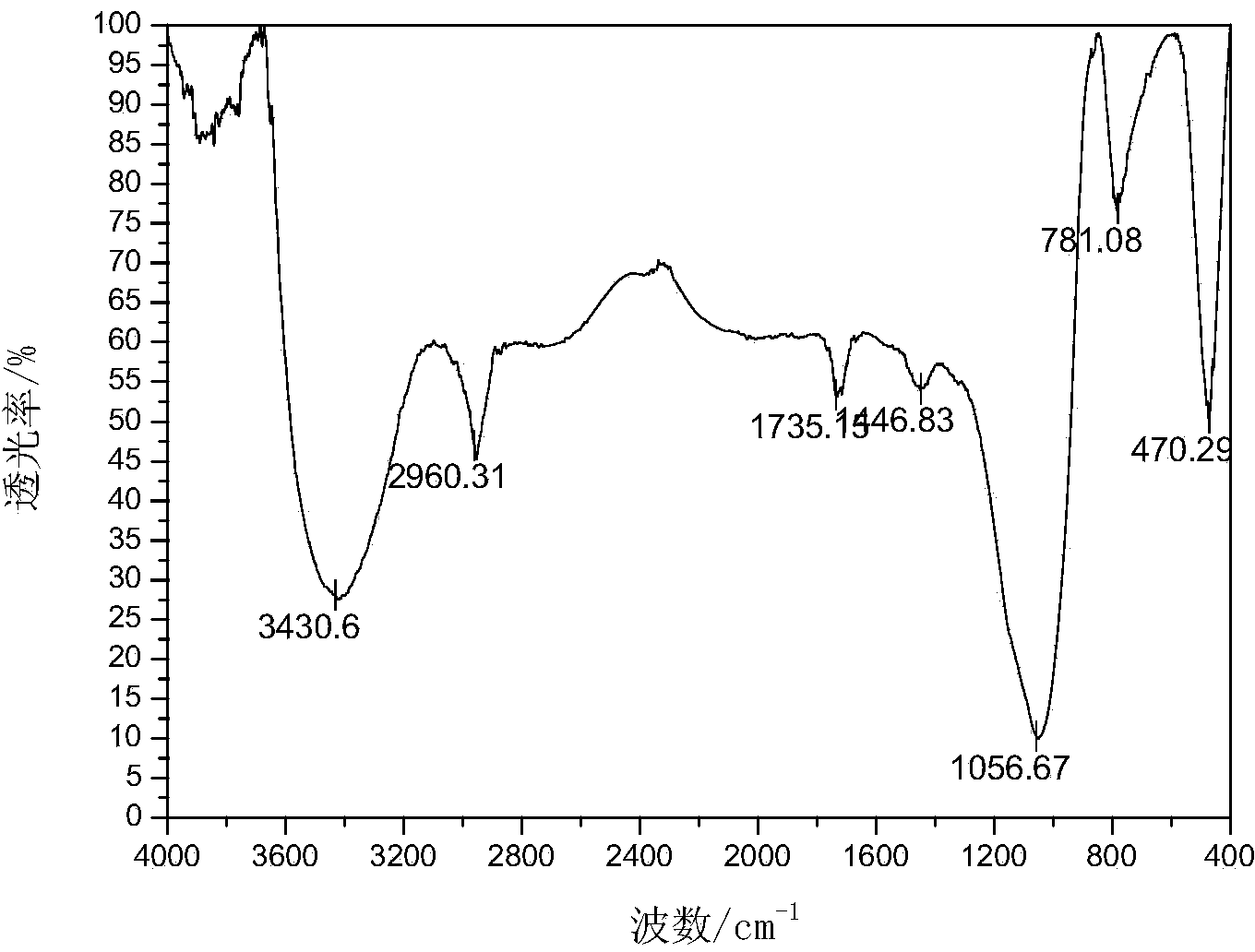

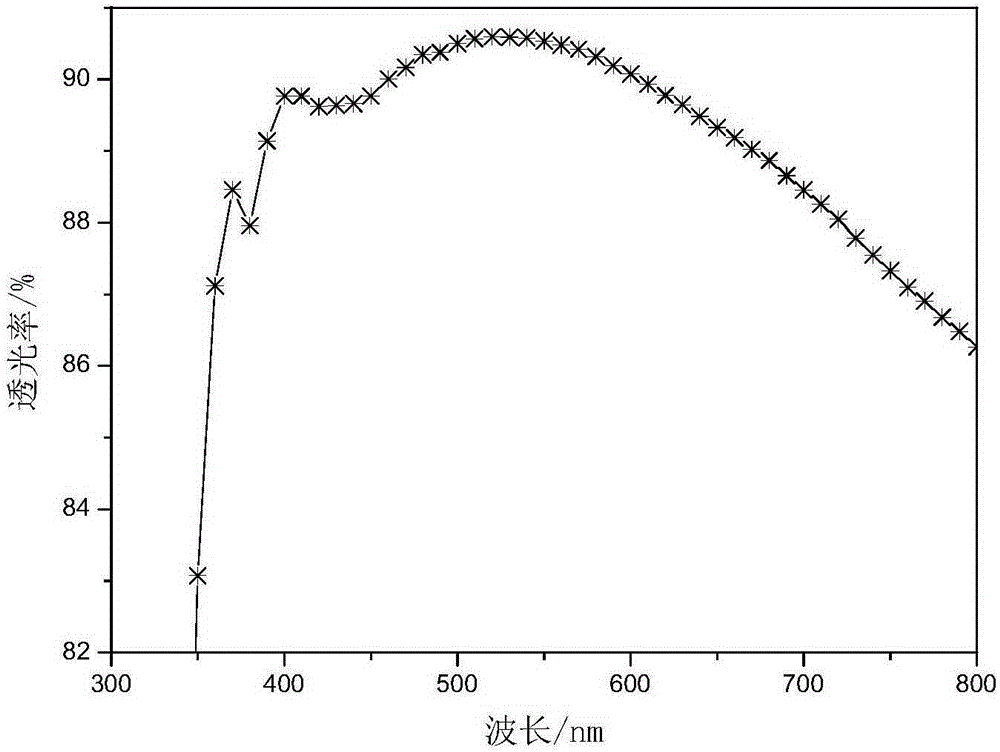

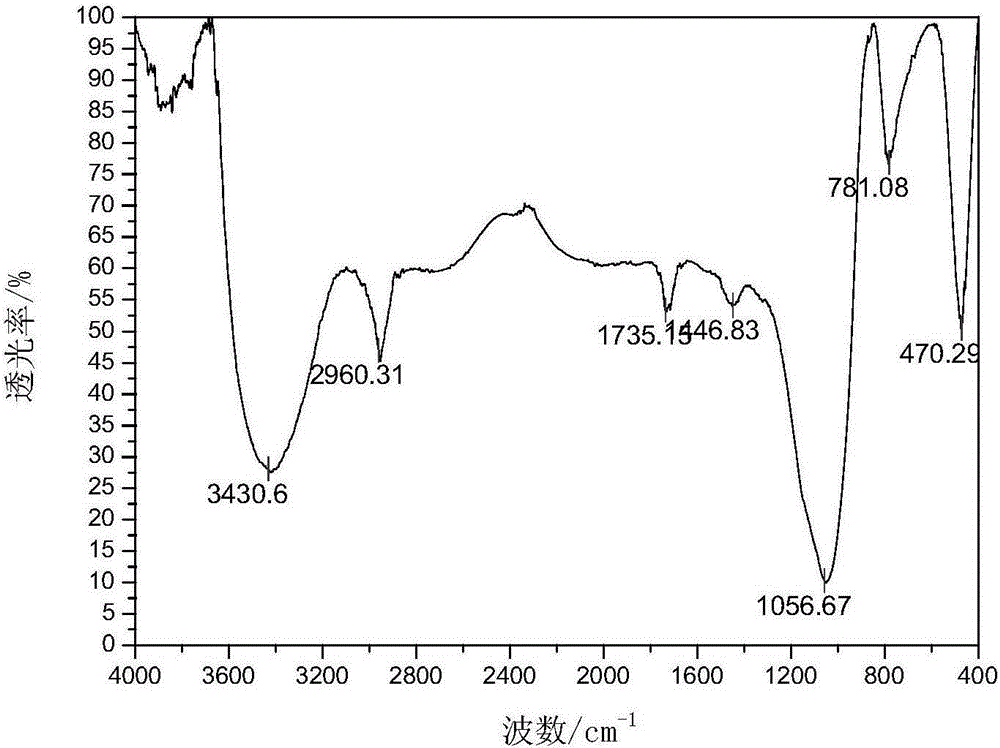

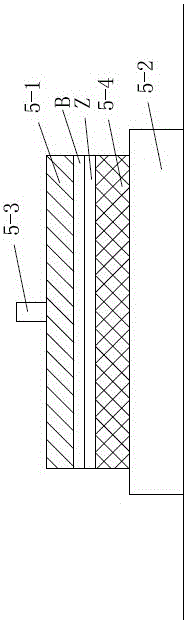

Antifogging coating, preparation method of antifogging coating and antifogging glass

InactiveCN103664004AImprove mechanical propertiesHas a hydrophilic functionSolubilityHeat resistance

The invention provides an antifogging coating, a preparation method of the antifogging coating and antifogging glass. The antifogging coating disclosed by the invention comprises at least one crosslinking layer and at least one antifogging layer, wherein the crosslinking layer and the antifogging layer are alternatively arranged to form the antifogging coating; the crosslinking layer plated on a base is arranged at one side of the antifogging coating; the antifogging layer is arranged at the other side. The antifogging coating has the advantages of being lasting in anti-fogging performance, and good in abrasive resistance, heat resistance and resistance to water solubility. The preparation method of the antifogging coating provided by the invention is scientific and reasonable in steps, simple and feasible in technology, low in cost and wide in application range. The antifogging glass provided by the invention has an excellent anti-fogging effect when the light transmittance is ensured.

Owner:DALIAN POLYTECHNIC UNIVERSITY

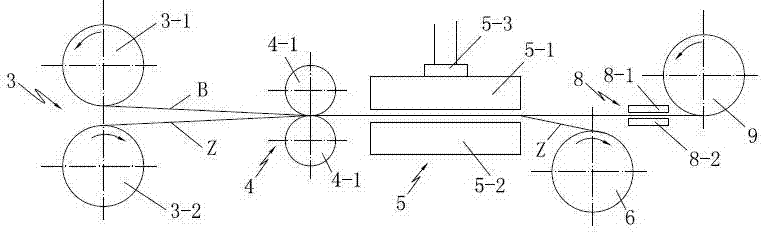

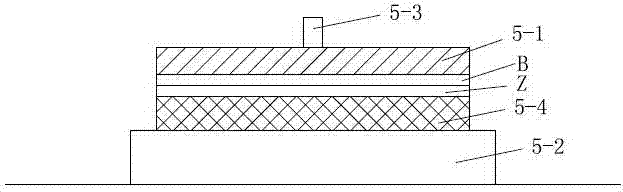

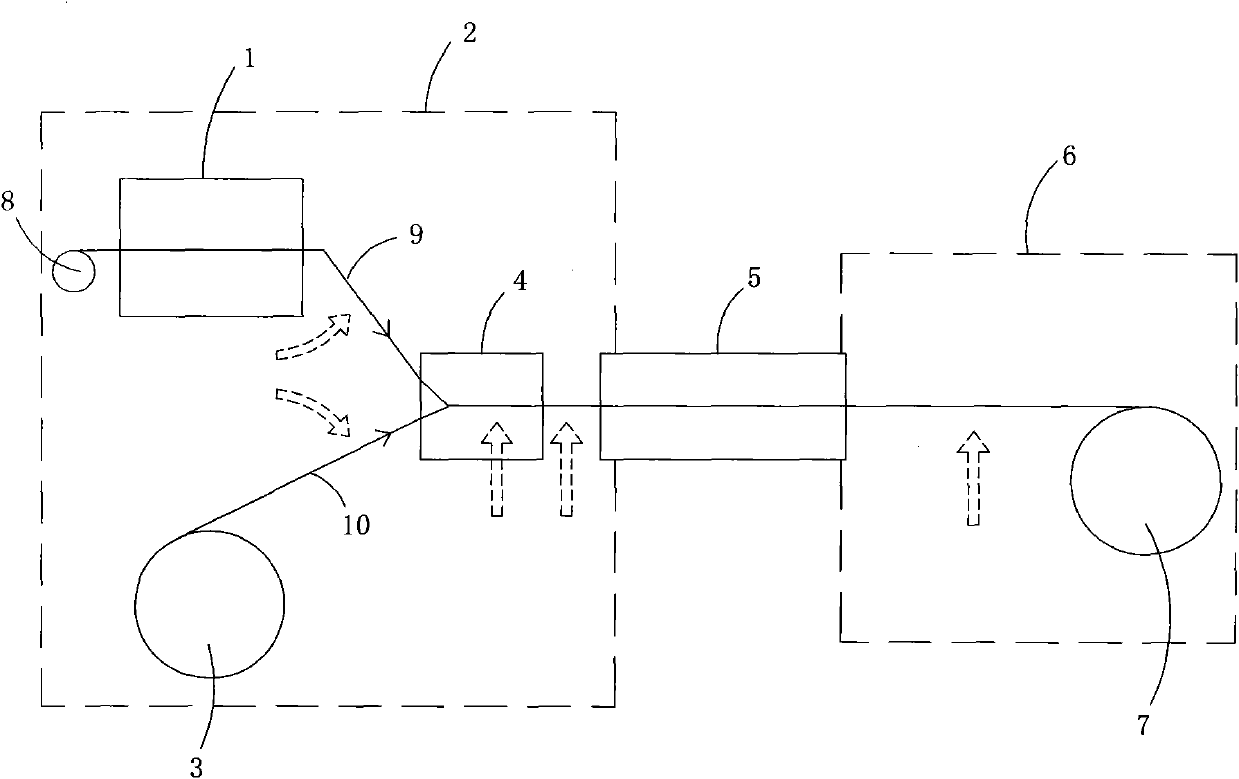

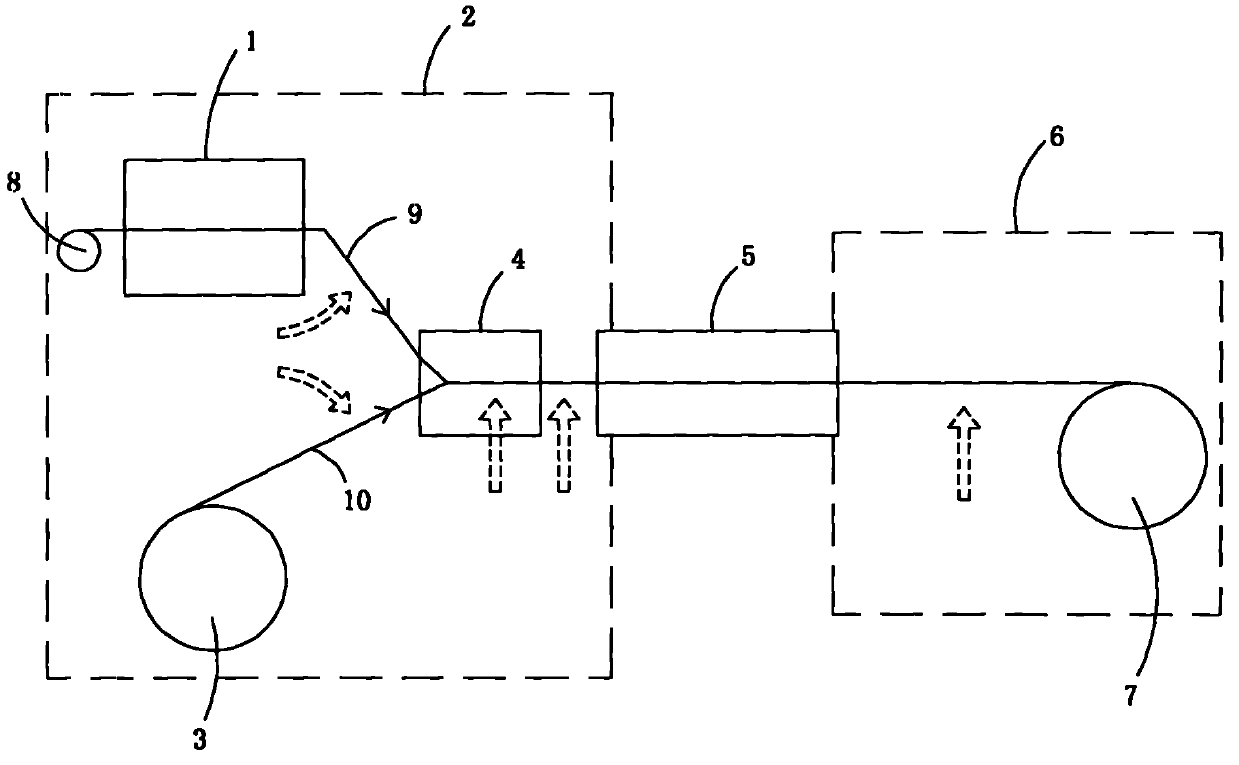

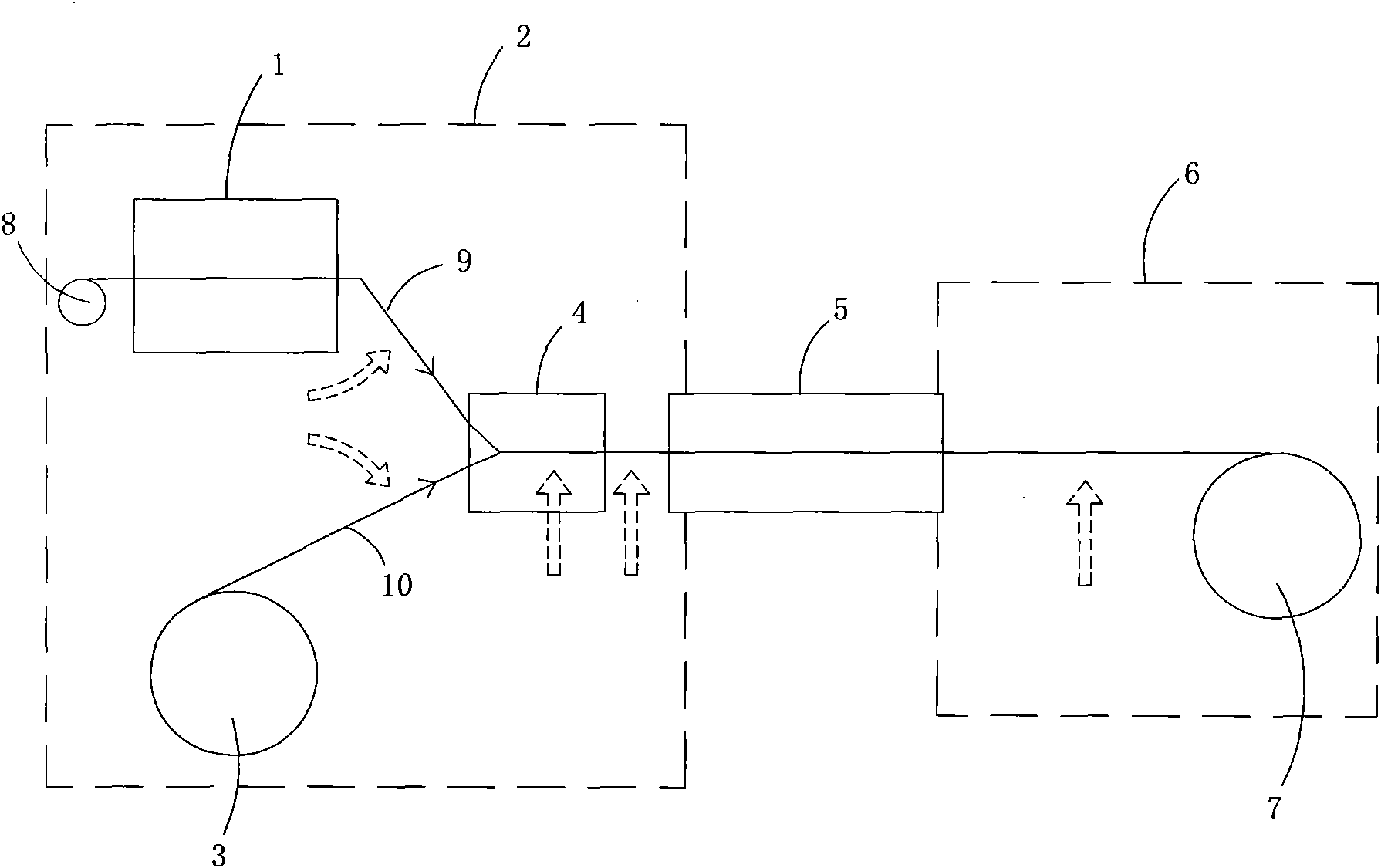

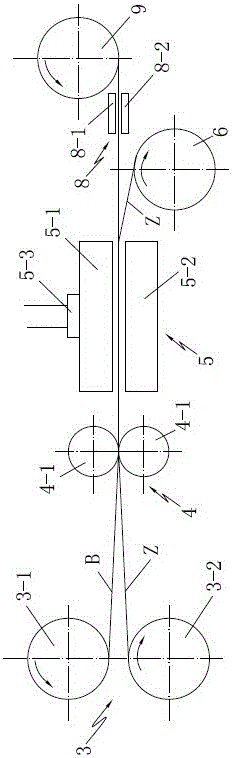

Concave and convex transfer printing chemical fiber fabrics and production process device and method thereof

InactiveCN104260545AGood quality guaranteedMethod steps are reasonableTransfer printingDyeing processCooking & bakingFiber

The invention discloses concave and convex transfer printing chemical fiber fabrics and a production process device and method thereof. The mechanical baking, the embossing process and the gas phase transfer printing process are combined together. The production process device is reasonable in structure. The production process method is simple and easy to control and the high quality concave and convex printing chemical fiber fabrics are produced. The existing blank key technology is filled and the technical support is provided for the gradually increased requirements for the concave and convex transfer printing chemical fiber fabrics.

Owner:陈立秋 +2

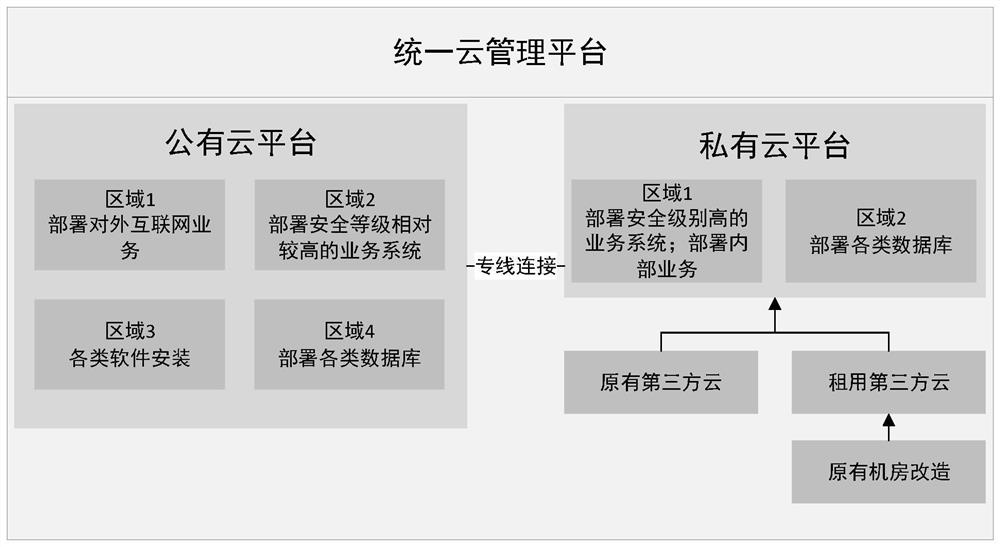

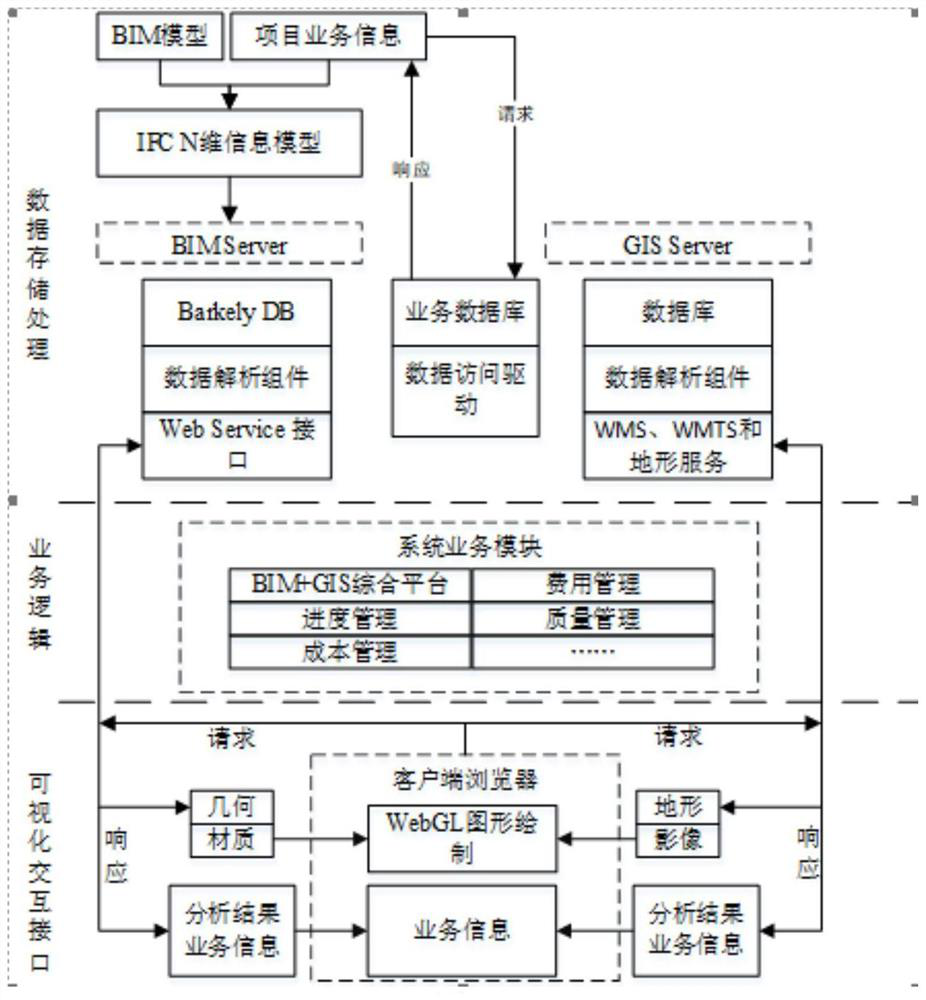

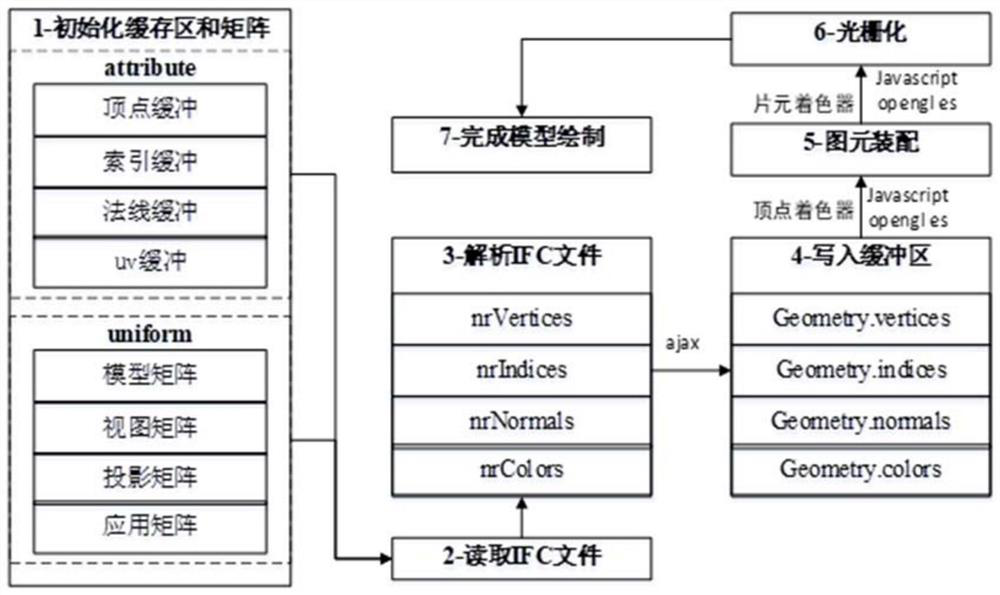

Building method and system for cloud platform based on BIM and GIS cooperative work

PendingCN111931278AImprove integration efficiencyImprove collaboration efficiencyGeometric CADCAD network environmentProcessingData store

The invention relates to a building method and system of a cloud platform based on BIM and GIS cooperative work. The invention belongs to the technical field of data processing, and is characterized in that the method comprises the steps: 1, building a cloud platform: enabling the cloud platform to comprise a public cloud platform, a private cloud platform, and a unified cloud management platformwhich carries out the data interaction with the public cloud platform and the private cloud platform; 2, establishing a hydropower engineering collaborative management framework based on BIM and GIS,wherein the hydropower engineering collaborative management framework comprises a data storage processing part, a business logic part and a visual interaction interface; and 3, performing remote cooperative work based on the BIM and the GIS. The invention aims at the defects of the traditional information exchange and management working mode. The invention provides a management method for realizing data sharing, convenient communication, tight cooperation, effective management and high visualization degree, the practicability is strong, the collaborative design efficiency is greatly improved,the management level and the design quality are improved, the cost is saved, and the requirements of all parties can be met.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

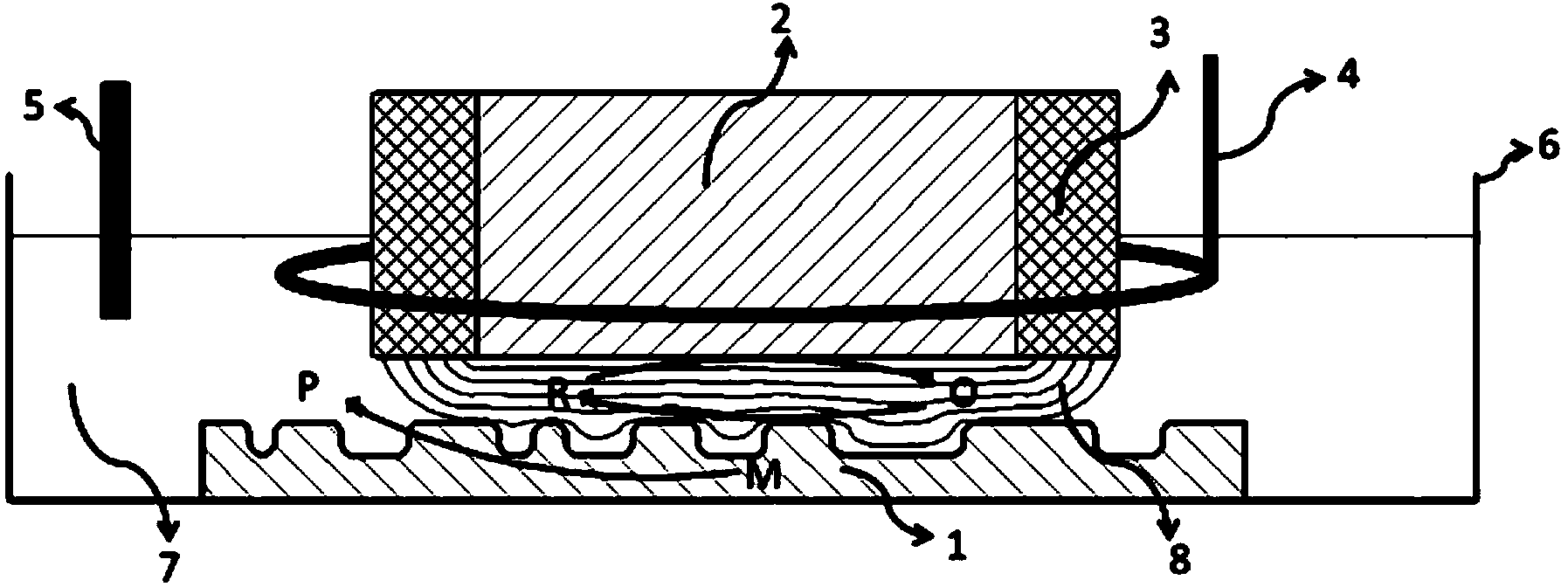

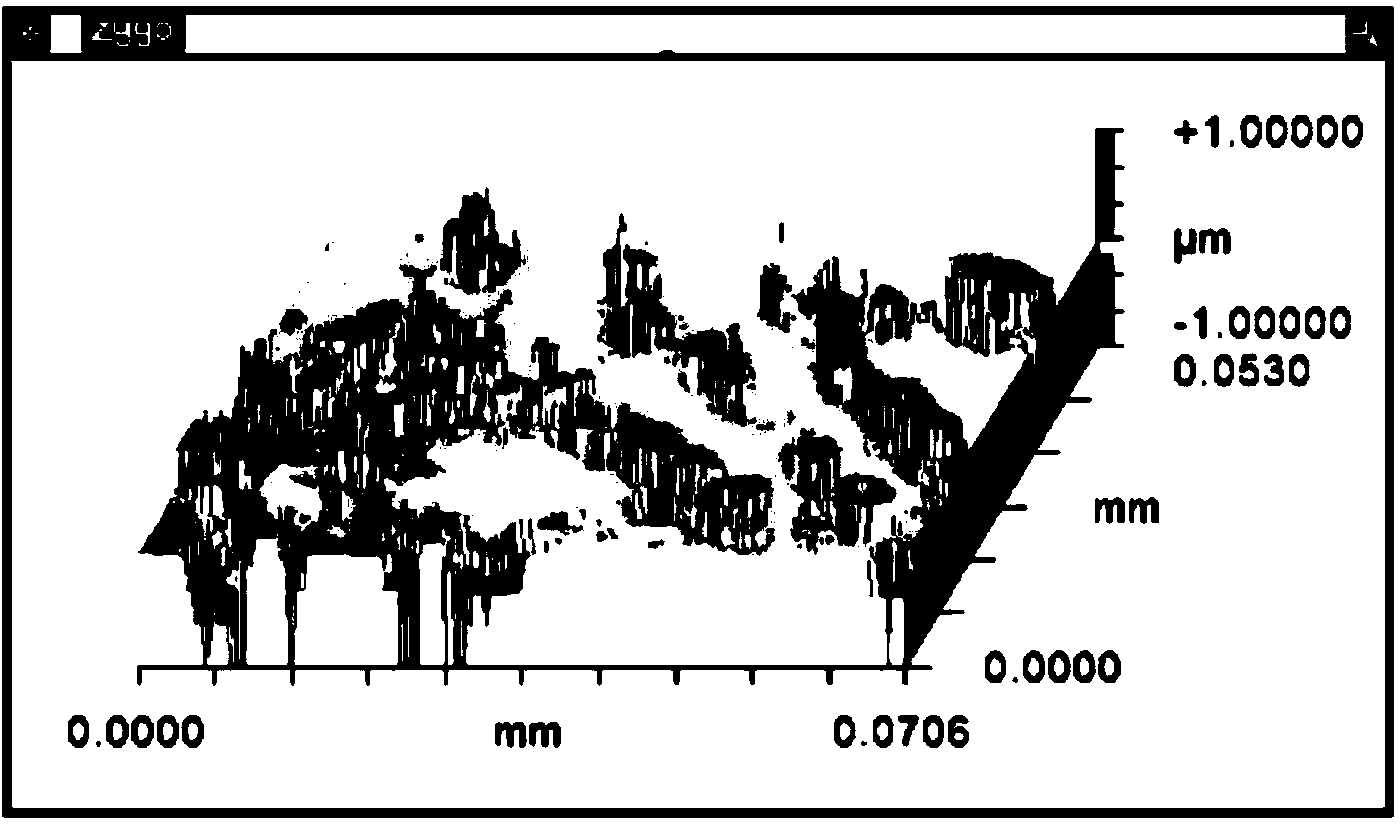

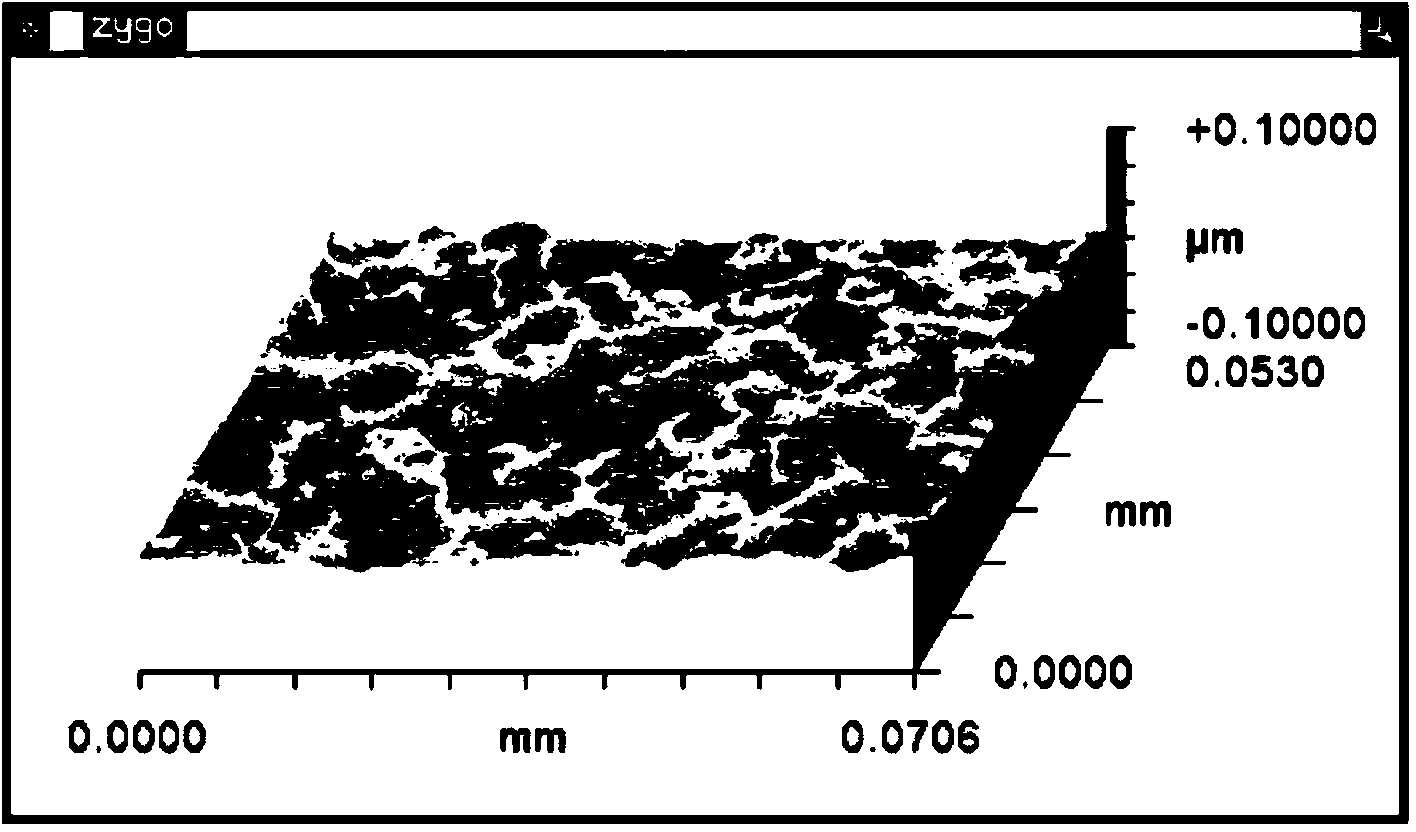

Electrogenerated chemical polishing method

ActiveCN103924287AAbility to selectively removeMethod steps scienceSemiconductor/solid-state device manufacturingMicro nanoElectrochemical response

The invention provides an electrogenerated chemical polishing method which comprises the following steps: preparing a working solution which contains an electroactive mediator, a pH regulating agent, a viscosity regulating agent and an inhibiting agent; parallelly and oppositely arranging the working surface of a working electrode and the surface of a workpiece, wherein the working surface of the working electrode has smoothness less than 1 micrometer; and immersing the working surface of the working electrode and the surface of the workpiece into the working solution, and regulating the spacing between the working surface of the working electrode and the surface of the workpiece to 0.05-20 micrometers through a micro-nano composite feeding mechanism. According to the method, a power supply is started to electrify the working electrode and an auxiliary electrode, the electroactive mediator near the working surface of the working electrode generates an etching agent through electrochemical reaction, and a local high point positioned on the surface of the workpiece is selectively etched in such a way that the etching agent is dispersed to the surface of the workpiece and generates diffusion controlled etching reaction, so that the unstressed polishing on the surface of the workpiece is realized.

Owner:DALIAN UNIV OF TECH +1

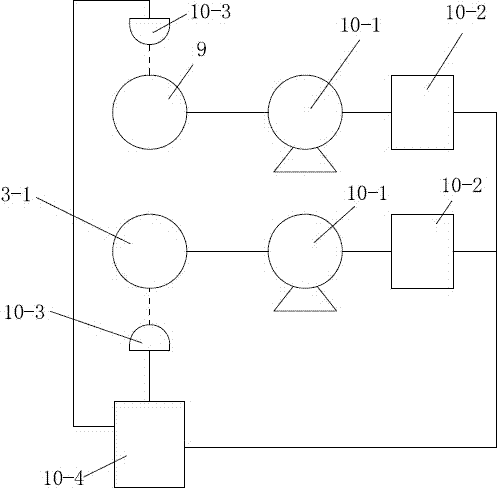

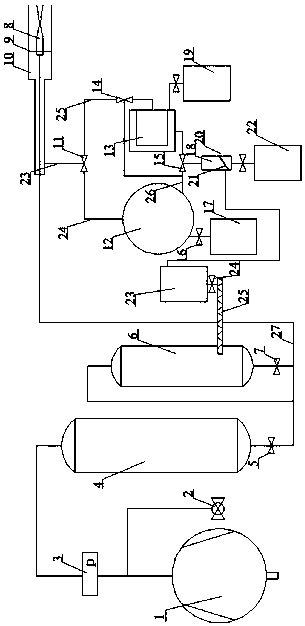

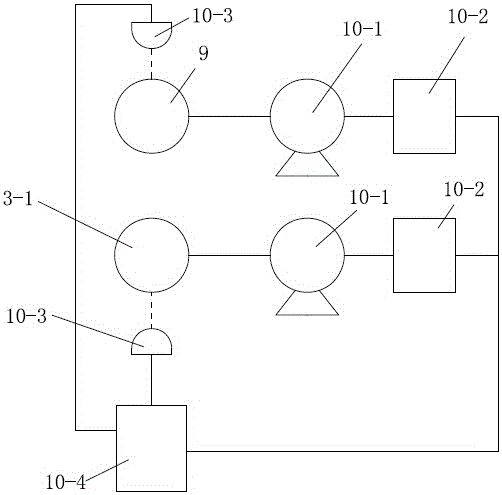

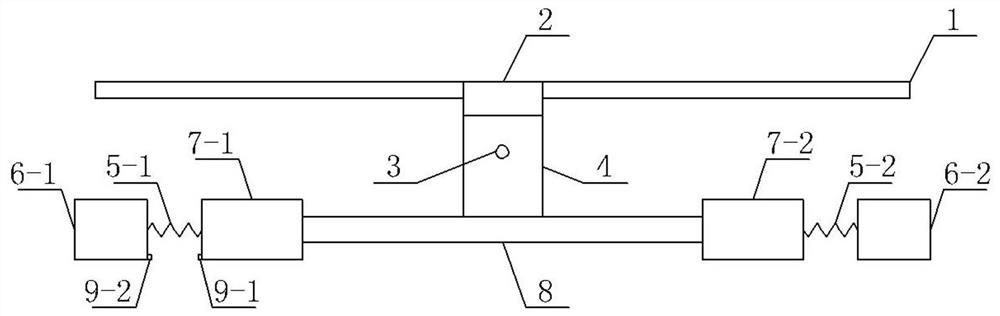

Device and method for recycling grinding material from grinding material gas jet

PendingCN107695898AIncrease profitAchieving processing powerAbrasive feedersAbrasive machine appurtenancesProcess engineeringAir compressor

The invention relates to a device and a method for recycling a grinding material from a grinding material gas jet. The device comprises an air compressor, a material storage tank, a nozzle, a magneticsorting machine, a gravity sorting machine and a grain size sorting machine; a grinding material recycling cover is arranged on a nozzle cover; a recycling pipe is connected with the grinding material recycling cover; the recycling pipe is respectively connected with a first conveying pipeline and a second conveying pipeline through a first three-way valve; the first conveying pipeline is connected with the magnetic sorting machine; a grinding material recycling port of the magnetic sorting machine is connected with a third conveying pipeline and the grain size sorting machine through a second three-way valve; the second conveying pipeline is connected with the third conveying pipeline and the gravity sorting machine through a third three-way valve; the grinding material recycling port ofthe gravity sorting machine is connected with the third conveying pipeline and the grain size sorting machine through the second three-way valve; the grinding material recycling port of the grain size sorting machine is connected with a grinding material recycling box; a discharging port of the grinding material recycling box is connected with a lateral feeding port of the material storage tank.The device and the method provided by the invention have the advantages that the grinding material use ratio of the grinding material gas jet is increased, the impurities and wastes in the jet operation are classified and treated, and the like.

Owner:HENAN POLYTECHNIC UNIV

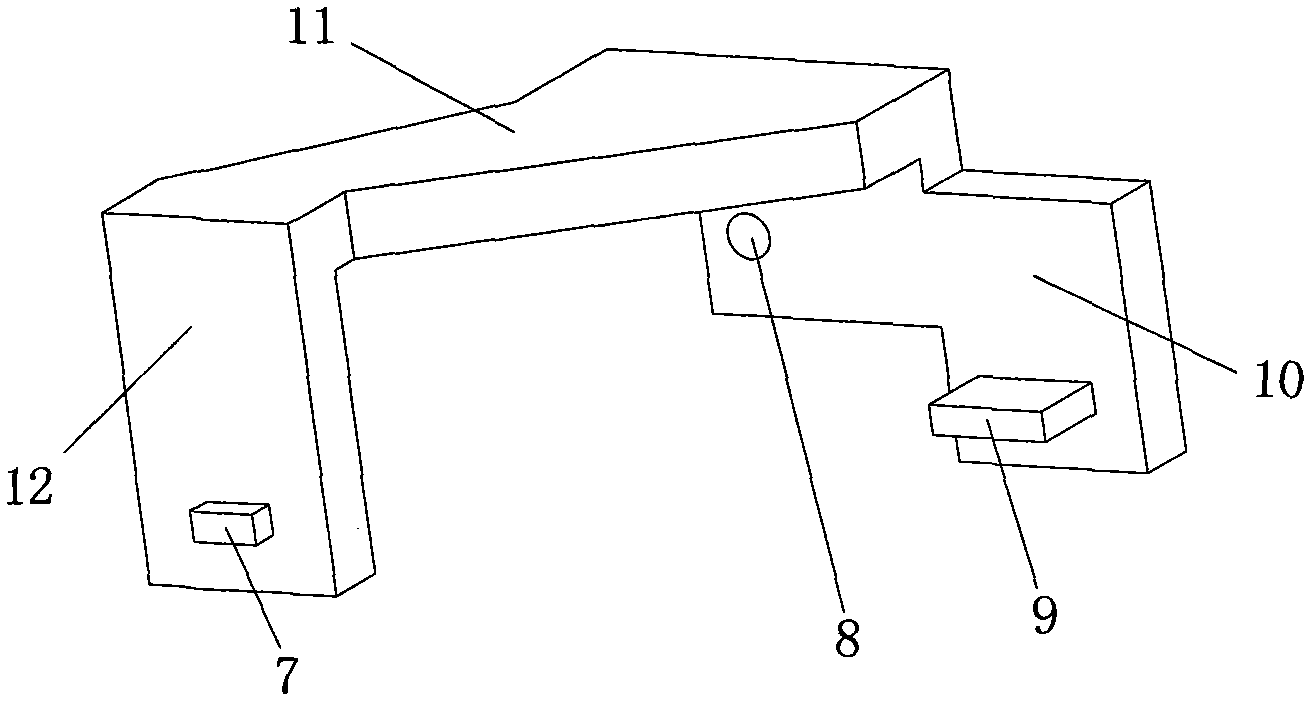

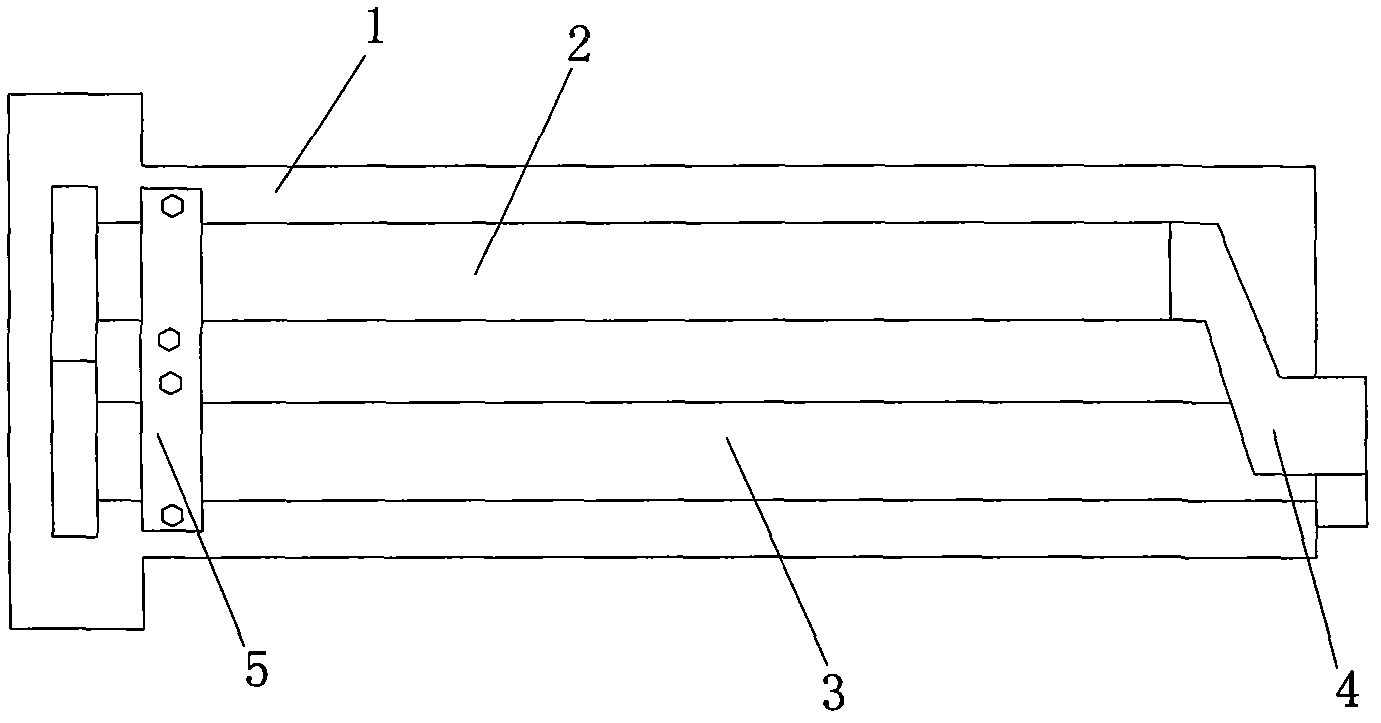

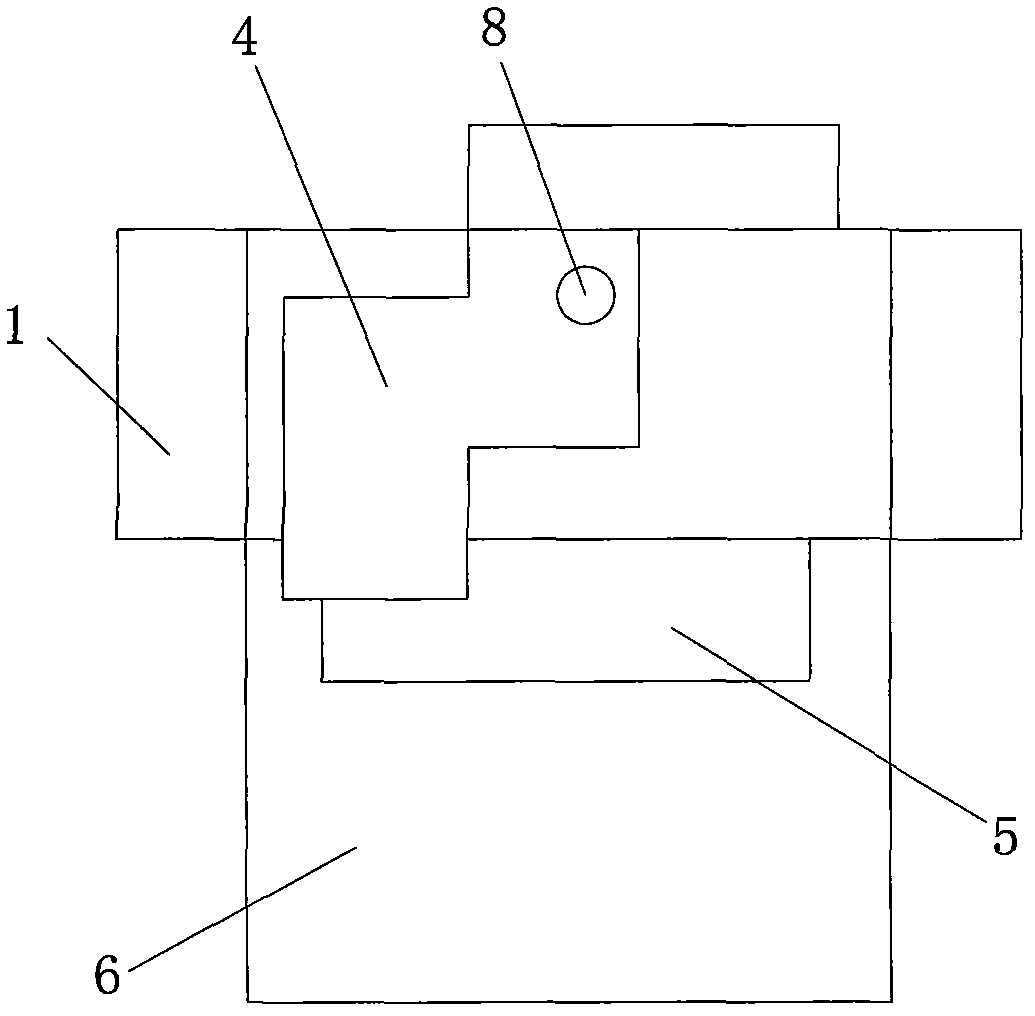

Method and tooling for installing camshafts

ActiveCN102059544ARealize subpackageMethod steps are reasonableMetal working apparatusEngineeringCamshaft

The invention discloses a tooling for installing camshafts, comprising a front arm, a rear arm and a connection arm, wherein the rear arm is provided with a bolt hole used for fixing the tooling on a framework, the front arm is provided with a first protruding key adaptive to a groove arranged on an air exhaust camshaft, the rear arm is provided with a second protruding key adaptive to a groove arranged on an air inlet camshaft, the front arm and the rear arm are parallel to each other, and when the camshafts are required to be separately assembled and fixed, the camshaft installing tooling can be used for carrying out separated assembly to satisfy the requirements of an assembling process on convenience and rapidness. The tooling has the advantages of simple structure, low cost and convenience in use.

Owner:CHERY AUTOMOBILE CO LTD

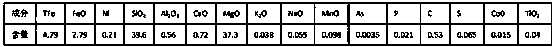

Technology of using asbestos tailings to produce silicon-calcium-magnesium-potassium fertilizer

ActiveCN109020629AReasonable stepsLittle environmental hazardMagnesium fertilisersPotassium fertilisersFertilizerCalcium magnesium

The invention discloses a technology of using asbestos tailings to produce a silicon-calcium-magnesium-potassium fertilizer. The technology comprises following steps: at first, grinding serpentine bya cone crusher to a size of 3 cm or so; then adding grinded serpentine into a ball milling machine, carrying out ball milling for 30 to 40 minutes, controlling the granularity of serpentine to be 250meshes or so; adding KCl particles into the ball milling machine, wherein the ratio of KCl particles to serpentine is 1:9, carrying out ball milling for 30 minutes, when the granularity of particles in the ball milling machine is greater than 300 meshes, discharging the powder to a winnowing machine, winnowing the powder under a pressure of 6 kg; after winnowing, directly packaging the powder, orusing the powder to product a fertilizer, discharging materials which are not winnowed from the rotating cylinder, and taking non-winnowed materials as a metallurgy raw material. The asbestos tailingsare processed harmlessly, the wastes are converted into valuable resources, and the environmental pollution is reduced.

Owner:北京璞域环保科技有限公司

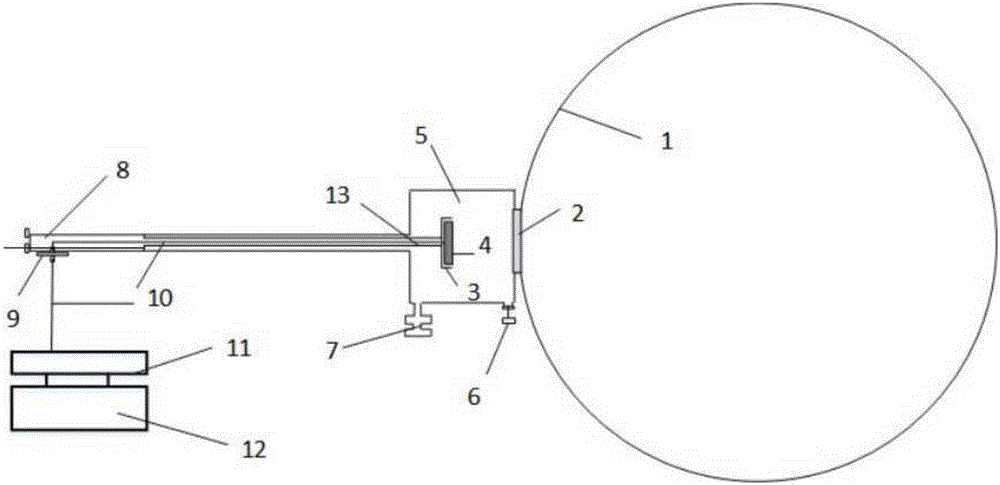

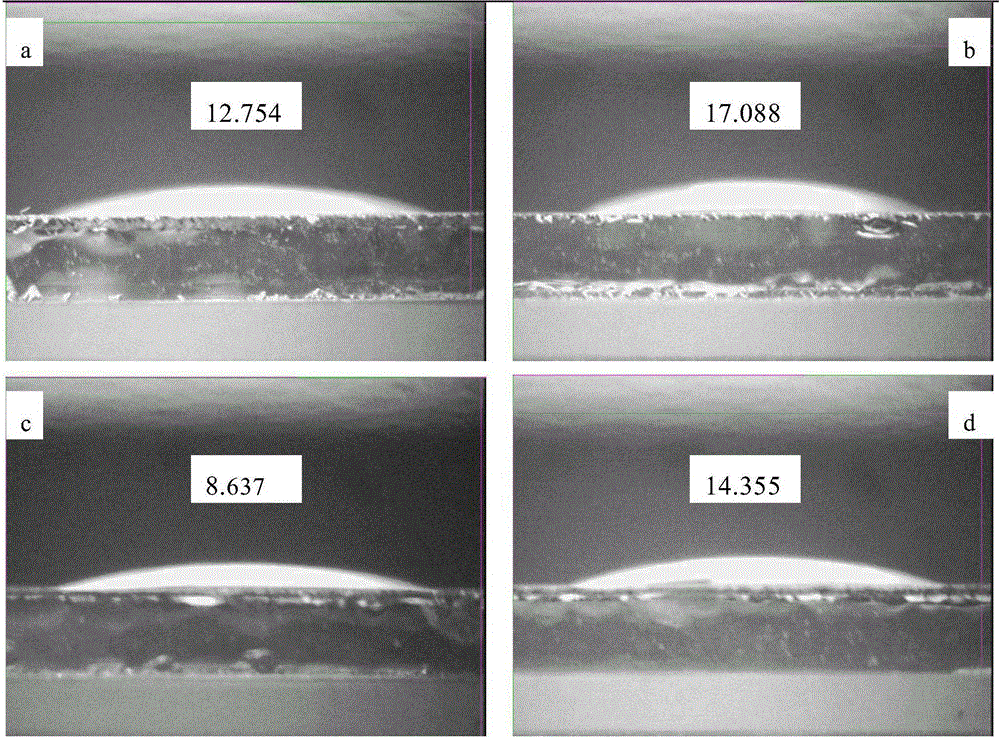

Method for cleaning first mirror in situ through radio frequency plasma

InactiveCN106064167AImprove sealingDoes not affect the vacuum environmentNuclear energy generationCleaning processes and apparatusSputteringCoaxial cable

The invention provides a method for cleaning a first mirror in situ through radio frequency plasma. The method is characterized in that a coaxial cable is adopted to introduce a radio-frequency power supply into a sample exchange chamber connected with a Tokamak device vacuum chamber, and the radio-frequency power supply is connected to the first mirror; the first mirror is pushed to the Tokamak device vacuum chamber through a sample conveying rod in the sample exchange chamber; the Tokamak device vacuum chamber is filled with a working gas, and the radio-frequency power supply is turned on to apply radio-frequency voltage to the first mirror; the radio-frequency power is gradually improved, a radio-frequency matcher is regulated to enable the radio-frequency reflection power to be zero, and the radio frequency plasma is generated on the surface of the first mirror; the self bias of the first mirror is regulated according to the category of surface deposition layers of the first mirror, and the surface deposition layers of the first mirror are cleaned through plasma sputtering; after cleaning for a certain time, the radio-frequency power supply is turned off and cleaning is stopped; and the first mirror sample is taken out through the sample exchange chamber and the sample conveying rod, and subsequent characterization is carried out.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Anti-fog coating, preparation method of anti-fog coating and anti-fog glass

InactiveCN103664004BImprove mechanical propertiesHas a hydrophilic functionSolubilityHeat resistance

Owner:DALIAN POLYTECHNIC UNIVERSITY

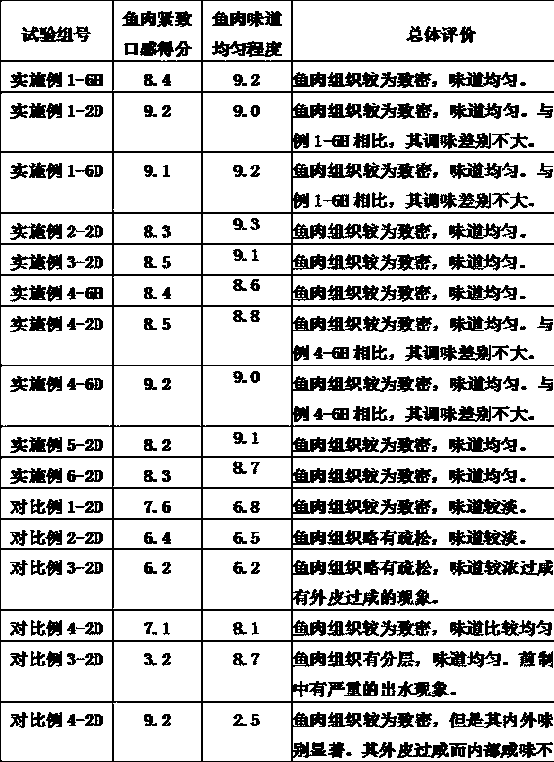

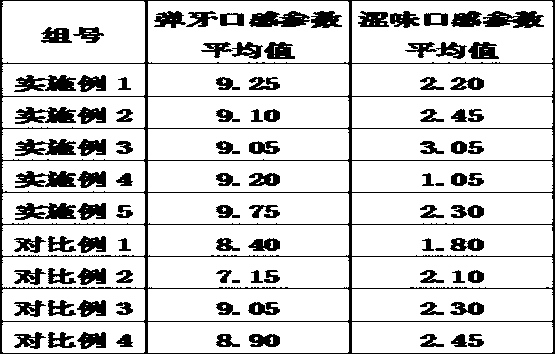

Preserving method of salmon meat

The invention discloses a preserving method of salmon meat. The preserving method comprises the following steps of (1) providing fresh salmon meat, cutting the fresh salmon meat into salmon meat slices, and performing beating; (2) washing the fresh salmon meat with clean water to remove bloodstain, and soaking the washed salmon meat with first pickling liquid; and (3) blowing the salmon meat obtained in step (2) with cold water to enable the surface of the salmon meat to be dry, and applying the surface of the dry salmon meat with second pickling liquid. The method is used for quickly picklingthe salmon meat, and the salmon meat being favorable in mouth feel is obtained. The method is reasonable in steps, feasible to operate, and high in pickling speed, and can be widely used in a pretreatment process of processing working procedures of salmon foods.

Owner:SHANDONG HOMEY AQUATIC DEV

Manufacture method and manufacture device of lapping isolated installation wire

ActiveCN102024529AImprove qualityBlack spot quality problem controlInsulating conductors/cablesDark spotEngineering

The invention discloses a manufacture method and a manufacture device of a lapping isolated installation wire. The method comprises the following steps: 1) according to a preset width, splitting a plastic film for later use; 2) cleaning and processing a wire in an alcohol pool; 3) wrapping and covering the split plastic film on the periphery of the wire by a covering machine in an anti-static device to obtain blank; 4) directly sending the blank from the outlet of the covering machine to a high-temperature sintering device, and sintering the blank at high temperature to obtain a semi-finishedproduct; and 5) sending the semi-finished product to an assistant dust-proof device, and cooling and processing the semi-finished product to obtain a finished product. The manufacture device comprises the covering machine, the high-temperature sintering device, the alcohol pool and the anti-static device, wherein the alcohol pool, the covering machine, the high-temperature sintering device and the anti-static device are integrally arranged on a frame shell. According to the invention, dark spots on the lapping installation wire of the finished product can be effectively avoided and the quality of the lapping installation wire of the finished product is improved.

Owner:浙江铁富隆线缆有限公司

Method for dyeing Shilin color on bobbin

InactiveCN108086016AReasonable stepsReasonable settingDyeing processLiquid/gas/vapor yarns/filaments treatmentColour fastnessYarn

The invention discloses a method for dyeing Shilin color on a bobbin. The method includes following steps: loosening the bobbin: loosening cheese; pretreating: using a pretreating aid to performing apretreating process conducive to dyeing on the cheese; dyeing: adding caustic soda into a dyeing vat at normal temperature, sucking prepared Shilin dye into the dyeing vat at normal temperature, enabling the dyeing vat to run for 16min, increasing temperature to 58 DEG C at a temperature increase rate of 1 DEG C / min, sucking in sodium hydrosulfite, and holding temperature for 40min; after-treating: discharging water in the dyeing vat, and performing aftertreatment processes like washing and softening on dyed cheese, wherein a weight ratio of the cheese, the pretreating agent, the caustic soda,the Shilin dye and sodium hydrosulfite is 440:225:200:4267:63. Chlorine bleach resistant color fastness of the cheese in the Shilin color obtained by using the method can reach Grade 4 (the testing standard is AATCC 188), and light fastness can reach Grade 4 of 20h.

Owner:佛山华丰纺织有限公司

Manufacture method and manufacture device of lapping isolated installation wire

ActiveCN102024529BImprove qualityBlack spot quality problem controlInsulating conductors/cablesAlcoholDark spot

The invention discloses a manufacture method and a manufacture device of a lapping isolated installation wire. The method comprises the following steps: 1) according to a preset width, splitting a plastic film for later use; 2) cleaning and processing a wire in an alcohol pool; 3) wrapping and covering the split plastic film on the periphery of the wire by a covering machine in an anti-static device to obtain blank; 4) directly sending the blank from the outlet of the covering machine to a high-temperature sintering device, and sintering the blank at high temperature to obtain a semi-finishedproduct; and 5) sending the semi-finished product to an assistant dust-proof device, and cooling and processing the semi-finished product to obtain a finished product. The manufacture device comprises the covering machine, the high-temperature sintering device, the alcohol pool and the anti-static device, wherein the alcohol pool, the covering machine, the high-temperature sintering device and the anti-static device are integrally arranged on a frame shell. According to the invention, dark spots on the lapping installation wire of the finished product can be effectively avoided and the quality of the lapping installation wire of the finished product is improved.

Owner:浙江铁富隆线缆有限公司

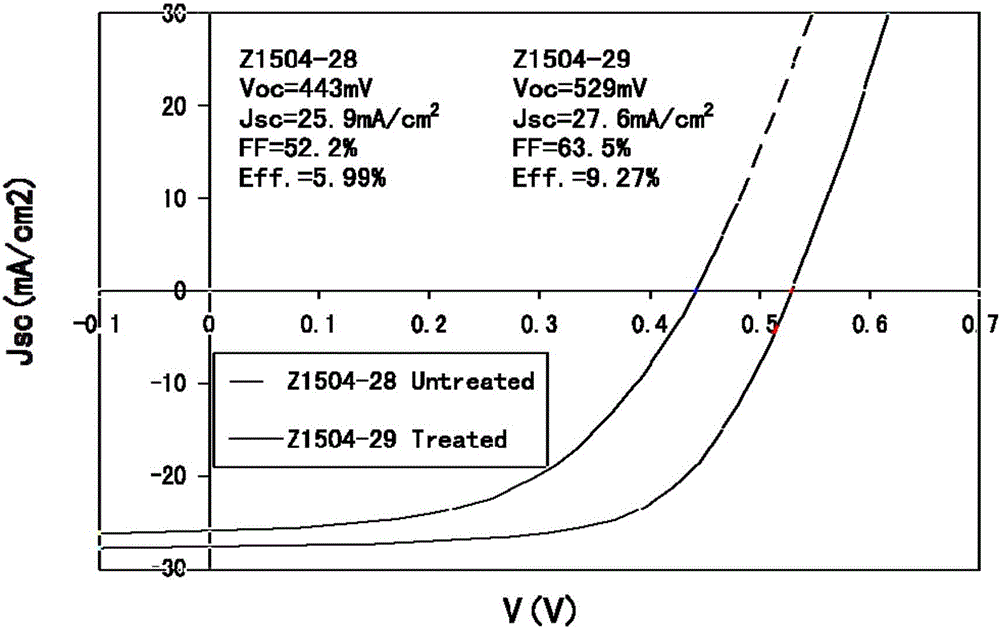

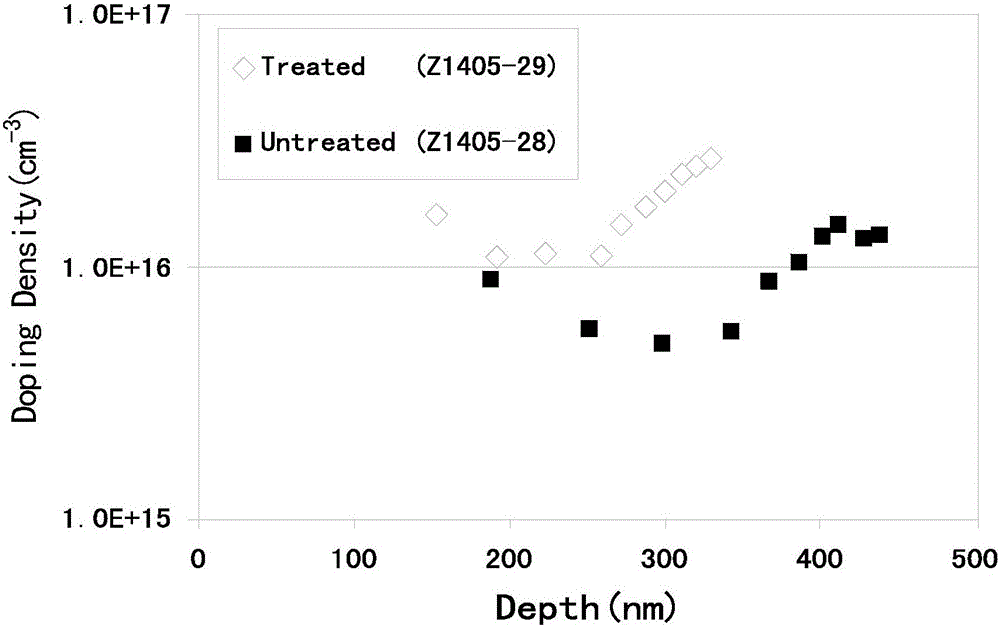

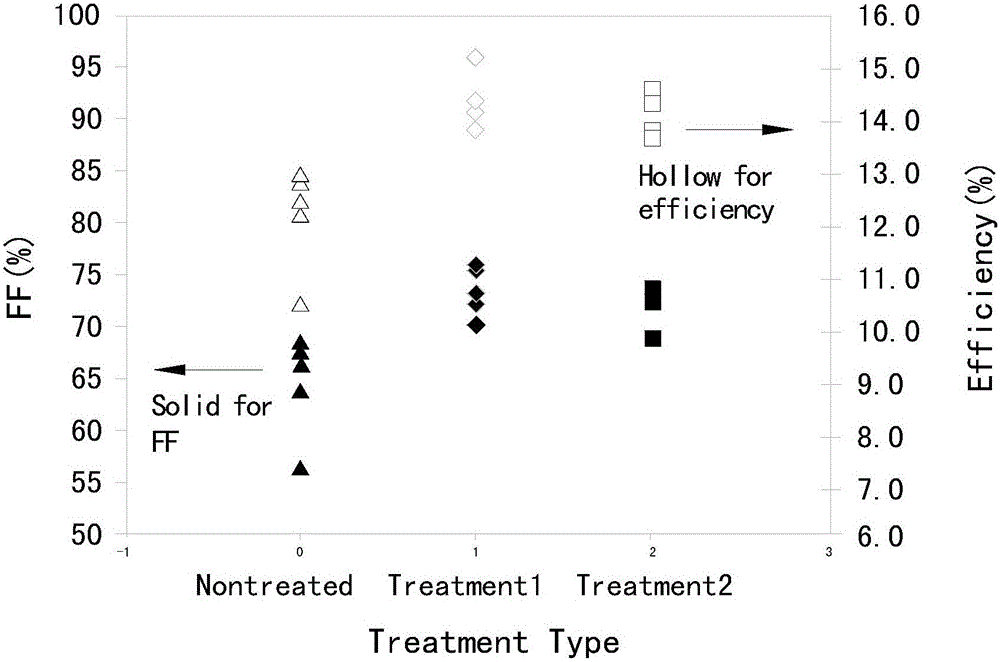

Treating agent after film formation of photoelectric absorption conversion layer of CIGS thin-film solar cell and use method thereof

ActiveCN105870000AEasy accessEasy to prepareFinal product manufactureSemiconductor/solid-state device manufacturingThioureaPotassium hydroxide

The invention provides a treating agent after film formation of a photoelectric absorption conversion layer of a CIGS thin-film solar cell. The treating agent is formed by mixing the following ingredients: water, sodium hydroxide, potassium hydroxide, ferric chloride, thiourea and ammonium hydroxide. The use method comprises the following steps: stirring and heating the treating agent to 40-90 DEG C; immersing a substrate with a solar cell CIGS photoelectric absorption conversion layer film into the treating agent for 20-60 minutes, and constantly swinging so as to enable the ingredients of the treating agent at the periphery of the thin film to be uniform; taking out the treated substrate, repeatedly flushing with deionized water until the resistance value of the deionized water is not less than 10 M ohm; removing residual water spots on the substrate by use of a mechanical spin-drying method, and baking for 10 minutes in an oven with the temperature of 150 DEG C . By virtue of utilizing the treating method and the use method which are provided by the invention to treat the photoelectric absorption conversion layer, precipitation of copper element in the thin film and reaction between surface copper element and oxygen are inhibited, so that the conversion efficiency is improved and an aging phenomenon of the thin film is avoided.

Owner:ANHUI HERZE CIGS TECH CO LTD

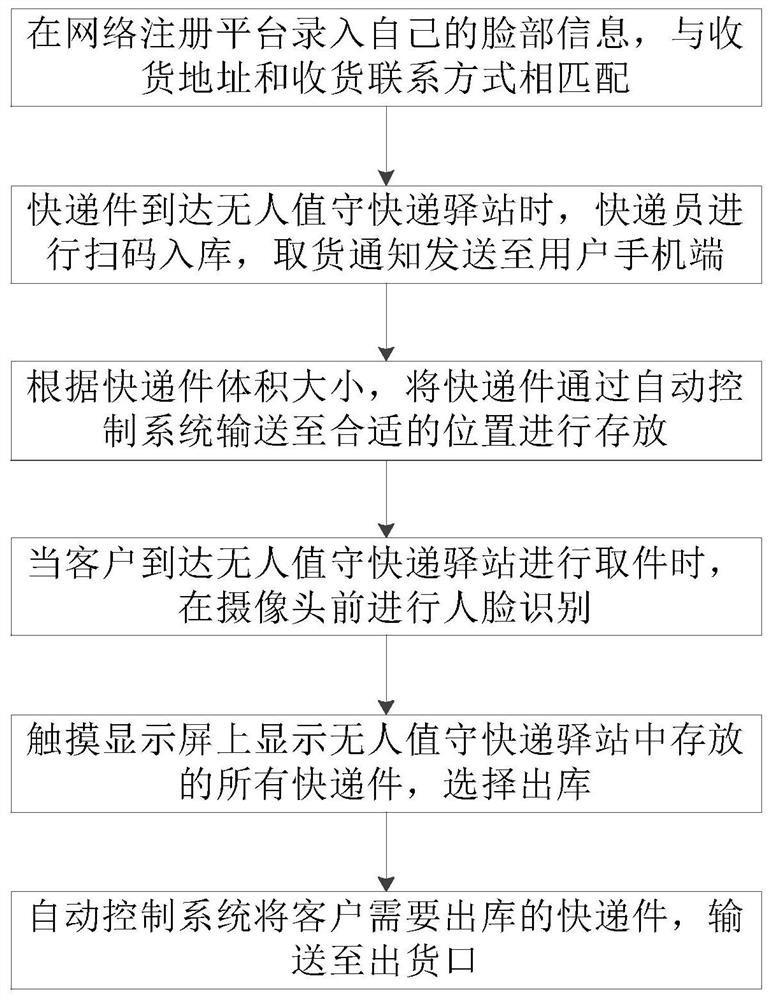

Express self-service pick-up method based on face recognition

PendingCN113011801AReasonable stepsEasy to implementCharacter and pattern recognitionLogisticsAutomatic controlReal-time computing

The invention discloses an express self-service pick-up method based on face recognition, and the method comprises the steps: 1, inputting the face information of a user in a network registration platform, and enabling the face information to be matched with a receiving address and a receiving contact way; 2, a courier scans a code for warehousing, and sends a pickup notice to a mobile phone terminal of a user; thirdly, automatic storage is carried out according to the size of the express; 4, performing face recognition in front of the camera during pick-up; 5, all the express items stored in the unattended express delivery station are displayed on the touch display screen, and the express items are selected to be delivered out of the warehouse; and sixthly, the automatic control system conveys the express parcels needing to be delivered out of the warehouse by the client to a goods outlet. The method is reasonable in step and convenient to implement, self-taking of the express in the unattended courier station is achieved through face recognition, convenience and rapidness are achieved, express logistics information can be inquired through face recognition, the use effect is good, and application and popularization are facilitated.

Owner:陈娅莉

Preparation method of pomfret instant food

The present invention discloses a preparation method of pomfret instant food and solves a problem that existing pomfrets are astringent and hard in taste in a direct cooking. The preparation method comprises the following steps: (1) fresh pomfrets are provided, the provided pomfrets are cut into blocks, the pomfret blocks are cooked, and fishbones are removed to obtain fish meat; (2) water is added to the pomfret meat obtained in the step 1 and papain is added to conduct an enzyme digestion; (3) corn starch, edible salt and whole egg liquid are added to enzymolysis slurry obtained in the step2, and the materials are mixed evenly to obtain fish meat slurry; and (4) the obtained fish meat slurry obtained in the step 3 is placed in a metal container to be steamed and molded, then the moldedfish meat slurry is cooled, the cooled molded fish meat slurry is de-molded, and the de-molded fish meat slurry is cut into a finished product. The method is reasonable in steps, advanced in technology, simple in preparation and feasible in operation. The prepared pomfret instant food by using the method is good in mouthfeel and taste, and has a wide application value.

Owner:SHANDONG HOMEY AQUATIC DEV

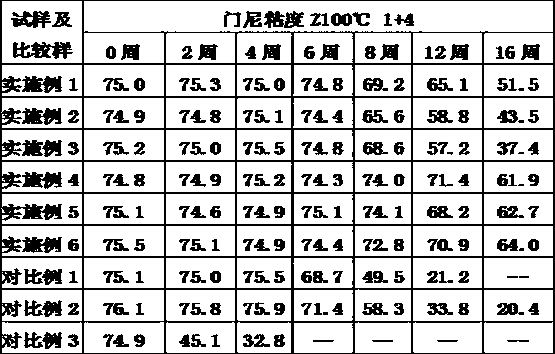

Antioxidant treatment method for isoprene rubber

InactiveCN107722306AImprove thermal stabilityImprove oxidation resistanceOxidation resistantThermal stability

The invention discloses an antioxidant treatment method for isoprene rubber. The antioxidant treatment method comprises the following steps: (I) mixing an antioxidant 1076, an antioxidant 412S, an antioxidant 1010 and an antioxidant 38, crushing and uniformly stirring to obtain a powdered compound antioxidant; granulating the powdered compound antioxidant in a granulator, and carrying out particlefinishing to obtain a columnar granular compound antioxidant; (II) dissolving the columnar granular compound antioxidant obtained in the step (I) in a solvent, adding into polyisoprene rubber latex,separating colloidal particles by adopting a hot water condensation method, and dehydrating the colloidal particles. The method disclosed by the invention has the advantages of reasonable steps, scientific antioxidant formula and feasible operation; the polyisoprene rubber obtained by the method disclosed by the invention has better thermal stability and longer-time oxidation resistance.

Owner:山东通泰橡胶股份有限公司

A method for extracting chondroitin sulfate from fish bones

The invention discloses a method for extracting chondroitin sulfate for fish bones. The method comprises the following steps: (1) fresh sea fish bones are used as raw materials, steaming and boiling are carried out, high pressure air is used for separation, in order to obtain fish flesh protein and fish bones; (2) fish bones obtained in the step (1) are cleaned and crushed, in order to obtain thefish bone powder; (3) fish bone powder obtained in the step (2) is added into enzymatic hydrolysate, heating and filtering are carried out, in order to obtain clear liquid; (4) ethanol is added into the clear liquid obtained in the step (3), and precipitates are collected; (5) precipitates obtained in the step (4) are leached and washed with a washing agent; (6) water is added into the precipitates obtained in the step (5) till dissolving, ethanol is added, and precipitates are collected and dried. Enzymatic hydrolysis and a washing method are combined in order to obtain chondroitin sulfate with lower anaphylaxis and other excellent characteristics. The method has reasonable steps, advanced technology, and feasible operation, and is suitable for extraction of chondroitin sulfate.

Owner:SHANDONG HOMEY AQUATIC DEV

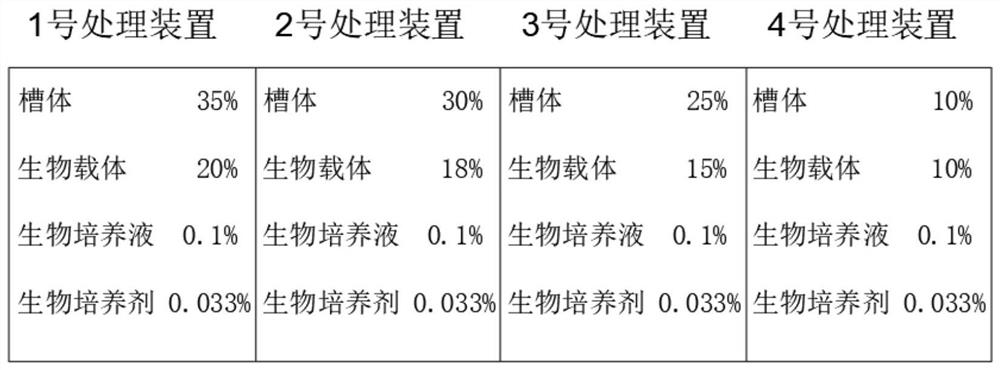

Construction method of microbial sewage treatment device

PendingCN112723556AMethod steps are reasonableImprove efficiencyBiological water/sewage treatmentSewage treatmentWater treatment

The invention discloses a construction method of a microbial sewage treatment device. The construction method comprises the following steps: constructing the device, arranging a wooden biological carrier in the treatment device, arranging a biological culture solution in the treatment device, and arranging a biological culture agent in the treatment device. Compared with the prior art, the method has the advantages that the steps are reasonable, through reasonable design of treatment device construction, the wooden biological carrier placement proportion, the culture solution placement proportion and the culture agent placement proportion, the microbial sewage treatment efficiency is greatly improved, the traditional construction cost is reduced, the construction efficiency is improved, the work load of personnel is reduced, the applicability is high, and popularization is convenient.

Owner:湖北汇农生物科技有限公司

A kind of method of using enteromorpha to prepare seaweed polysaccharide oral liquid

ActiveCN107874173BReduce heavy metal contentExtensive processingFood ingredient functionsFood extractionBiotechnologyMicrobiology

The invention discloses a method for preparing seaweed polysaccharide oral liquid by using Enteromorpha, which comprises the following steps: (1) providing fresh Enteromorpha, drying it, cutting it into sections, and soaking it in soaking liquid; (2) using Enteromorpha Wash with clean water and spin dry, add clean water to heat and stir, then filter, wash with clean water and spin dry; (3) Add NaOH aqueous solution to Enteromorpha enteromorpha, and extract three times, combine the three extracts; (4) combine The final extract was concentrated, and 95% ethanol was added to collect the precipitate; (5) water was added to the precipitate obtained in step 4 to dissolve, then 95% ethanol was added to collect the precipitate, and the precipitate was dried under reduced pressure, and Add water to dissolve to obtain seaweed polysaccharide oral liquid. The method of the invention can prepare the seaweed polysaccharide oral liquid with lower heavy metal content. The method has reasonable steps and advanced technology, and can be widely used in processing enteromorpha.

Owner:荣成海锐芯生物科技有限公司

A kind of preparation method of instant trotter product

The invention discloses a making method of a ready-to-eat pig's trotter food. The making method comprises the following steps of (1) removing hair and cutin from a fresh pig's trotter, and cutting thetreated pig's trotter into two parts long a line between two toes; (2) soaking pig's trotter blocks obtained in step (1) in a soaking composition, and transferring the pig's trotter blocks and a first soaking composition to a high-pressure reactor for heating; (3) draining the pig's trotter blocks obtained in step (2), coating the drained pig's trotter blocks with a first coloring composition andperforming baking; and (4) performing cooking on the pig's trotter blocks obtained in step (3), and performing vacuum packing. The ready-to-eat pig's trotter food obtained by the method disclosed bythe invention has low fat content, and has uniform and bright color. The color of the ready-to-eat pig's trotter food is independent of dye pigment, and the ready-to-eat pig's trotter food has good market acceptance degree. The method is reasonable in steps, and reliable to prepare, and can be widely applied to process pig's trotter foods and pork rind foods.

Owner:山东明鑫集团有限公司

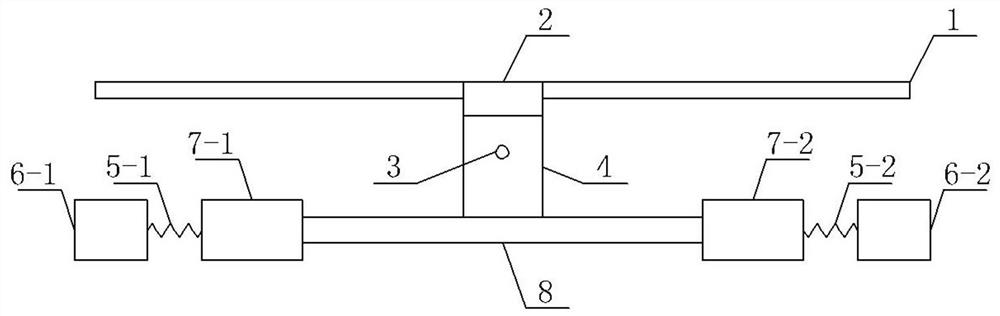

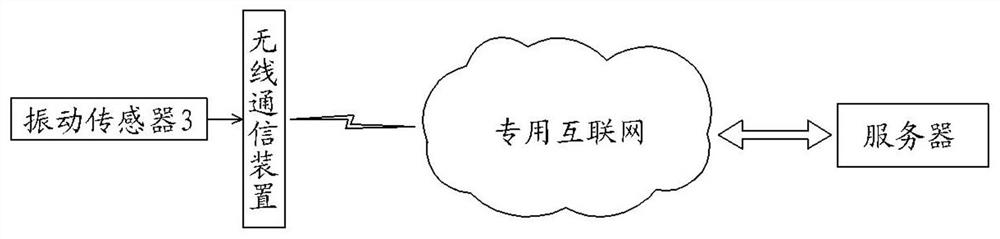

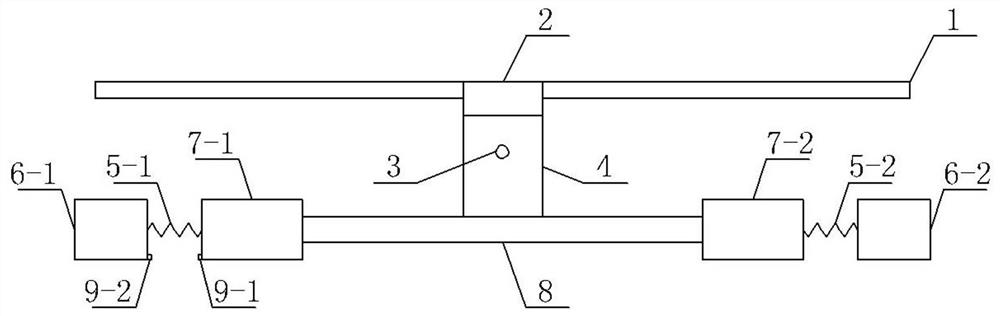

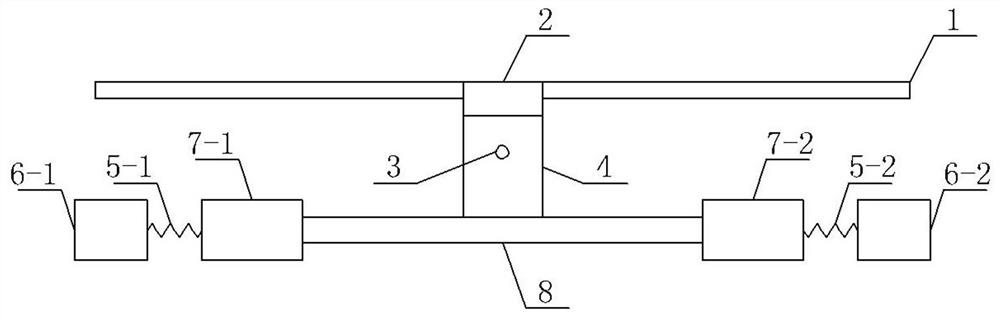

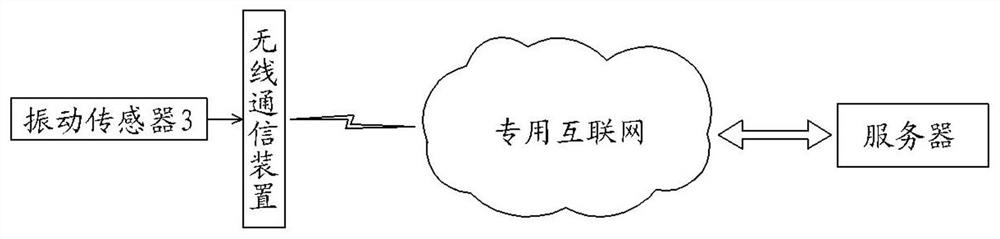

Self-adjusting damper with real-time monitoring function

ActiveCN112701643AImprove the anti-vibration effectStable structureDevices for damping mechanical oscillationsMeasurement devicesDamperSelf adjusting

The invention discloses a self-adjusting damper with a real-time monitoring function, and belongs to the technical field of breeze vibration prevention of power transmission wires. The self-adjusting damper comprises a connecting piece, amain hammer head and an auxiliary hammer;the connecting piece is used for being connected with a wire, and the main hammer head and the auxiliary hammer head are arranged on the connecting piece and used for preventing the wire from vibrating. Through the connecting piece, the main hammer head, the auxiliary hammer head and the like, the anti-vibration effect of the anti-vibration hammer is improved.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +1

Power transmission line external force damage intelligent identification method based on intelligent sensing terminal

InactiveCN112069855AImprove recognition rateMethod steps are reasonableImage enhancementImage analysisDevice CameraDigital camera

The invention discloses a power transmission line external force damage intelligent identification method based on an intelligent sensing terminal. The method is reasonable in step and convenient to operate stably. The sensing terminal is connected with a corresponding network data aggregation server, a plurality of network data aggregation nodes, a branch box monitoring unit, a meter box monitoring unit, a user power supply monitoring module box body, an internal storage battery, a power supply management board, an ARM image processing board, an infrared analog camera, a digital camera, a GPSmodule and a solar cell panel arranged outside the box body, a target recognition machine, a server and a mobile phone mobile terminal comprising a 4G module, the infrared analog camera is connectedwith the ARM image processing board and is used for acquiring image data of a power transmission line and sending the acquired image to the target recognition machine through the 4G module; The methodis reasonable in step and stable in effect, and the tedious step of manually selecting features is liberated; the method is high in dangerous operation target recognition rate, is high in recognitionrate, and can guarantee the real-time requirements.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

High-efficiency planting method of sesame

InactiveCN110506576AIncrease productionGuaranteed outputPlant cultivationCultivating equipmentsThinningAgronomy

The invention discloses a high-efficiency planting method of sesame. The method comprises the following steps of bedding and sowing, weeding, thinning, fertilization, insect control and harvesting. The method has reasonable steps and is convenient to operate, the yield of the sesame can be increased, and the quality is good; not only can the yield of the sesame be greatly increased, but also the quality of the sesame can be ensured, and the income of growers is increased.

Owner:XUZHOU CITY JIAWANG DISTRICT LUOZI AGRI TECH CO LTD

A kind of preparation method of reflective material

ActiveCN106363938BImprove structural stabilityIncrease reflectionOptical articlesTectorial membraneFree cooling

The invention discloses a preparation method for a novel reflective material. The preparation method comprises the steps that 1, elastic stretching resin and reflective glass beads are uniformly blended at the ratio of not less than 100:43, so that a first reflective mixture is formed and used for standby application; 2, a sheet is provided; 3, the first reflective mixture is printed on the surface of the sheet through a silk screen; 4, the sheet is subjected to constant temperature furnace roasting and natural cooling; 5, silver powder and elastic stretching resin are uniformly blended at the ratio of 100:400, so that a second reflective mixture is formed and printed on the backface of the sheet; 6, the sheet is subjected to constant temperature furnace roasting and natural cooling; 7, printing patterns are printed on the surface and the backface of the sheet; 8, the sheet is subjected to constant temperature furnace roasting and natural cooling; 9, the sheet is totally dried through drying equipment; 10, the sheet is roasted through an oven; 11, the sheet is molded through molding equipment; 12, machining and trim treatment are conducted; 13, integral molding is conducted through EPS molding equipment, foaming equipment and steaming equipment; 14, trim treatment is conducted again, an EPS material is poured into a mold, and then demolding is conducted after cooling; and 15, after demolding is completed, a protective film is pasted on the sheet.

Owner:岳阳市思博尔运动用品有限公司

Printed chemical fiber fabric with concave-convex transfer printing and its preparation process equipment and preparation method

InactiveCN104260545BGood quality guaranteedMethod steps are reasonableTransfer printingDyeing processProcess equipmentGas phase

Disclosed in the invention is a printed chemical fiber fabric with concave-convex transfer printing and its preparation process equipment and preparation method. The technical equipment with reasonable structure, and the specific method for preparing high-quality concave-convex printing chemical fiber fabrics, which are simple and easy to control, fill the key technology that is still in the blank, and provide technical support for meeting the growing needs of the society for concave-convex transfer printing chemical fiber fabrics.

Owner:陈立秋 +2

A self-adjusting anti-vibration hammer with real-time monitoring

ActiveCN112701643BImprove the anti-vibration effectStable structureDevices for damping mechanical oscillationsMeasurement devicesStructural engineeringControl theory

The invention discloses a self-adjusting anti-vibration hammer with real-time monitoring, and relates to the technical field of anti-vibration of power transmission wires; it includes a connecting piece used to connect with the wire, and a main hammer head arranged on the connecting piece to prevent the wire from vibrating And the auxiliary hammer head; it improves the anti-vibration effect of the anti-vibration hammer through the connecting piece, the main hammer head and the auxiliary hammer head.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +1

A kind of preparation method of kelp fermentation liquid

ActiveCN107594515BGreat tasteHigh in polysaccharidesMilk preparationFood scienceBiotechnologyCellulose

The invention discloses a preparation method of fermentation broth of Laminaria japonica. The method comprises the following steps: (1) fresh Laminaria japonica is selected, silt on the surface is cleaned and removed, and Laminaria japonica is cut into particles; (II) Laminaria japonica particles obtained in the step I are immersed in immersion liquid, after immersion is finished, the materials are fished out, and clear water is used for flushing and water is drained; (III) after immersion is finished, Laminaria japonica is beaten into pulp form, and water is added for dilution; (IV) milk powder, sucrose and carboxymethyl cellulose are added into Laminaria japonica normal juice, and heating and disinfection as well as cooling are carried out; (V) Kluyveromyces marxianus yeast and Streptococcus thermophilus are inoculated to a Laminaria japonica juice medium, and heating and inactivation are carried out; (VI) fermentation pulp is filtered in order to obtain clear liquid, and a final product is obtained. The method can be used in order to obtain nonallergenic Laminaria japonica fermentation broth with good mouthfeel and high polysaccharide content. The method has the advantages of reasonable steps, advanced technology, and feasible operation, and can be widely applied to deep processing of Laminaria japonica.

Owner:SHANDONG HOMEY AQUATIC DEV

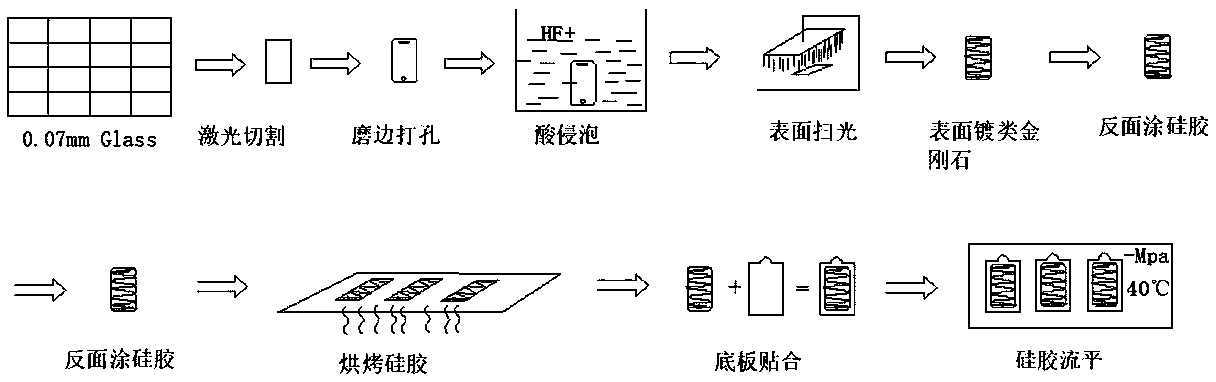

Manufacturing method of curved screen glass protective film

InactiveCN110868483AMethod steps are reasonableSuper scratch resistanceCoatingsTelephone set constructionsThin membraneSmart phone

The invention discloses a manufacturing method of a curved screen glass protective film. The manufacturing method comprises the following specific steps: step 1, cutting glass and edging the glass into any mobile phone screen size required by people; 2, putting the edged glass into an acid solution, and soaking the glass for 10-15 minutes; 3, polishing the surface of the soaked glass; 4, electroplating a layer of film on the front surface of the polished glass to obtain coated glass; 5, uniformly smearing silica gel on the reverse side of the coated glass, and then performing drying at low temperature to obtain a semi-finished product; and step 6, pasting a bottom plate on the surface, coated with the silica gel, of the semi-finished product, and then carrying out silica gel defoaming andleveling treatment to obtain a finished product. The method is reasonable in step, the prepared finished product can be attached together along with use of the smart phone, the finished product can bebent and folded at will, the surface of the glass protective film has super-strong scratch resistance, the effect of protecting the flexible screen is perfectly achieved, and wide use prospects are achieved.

Owner:SHENZHEN GOBELIKE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com