A self-adjusting anti-vibration hammer with real-time monitoring

A real-time monitoring and self-adjusting technology, applied in measuring devices, mechanical vibration damping devices, instruments, etc., can solve the problems of poor anti-vibration effect of anti-vibration hammer, and achieve the effect of improving the anti-vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

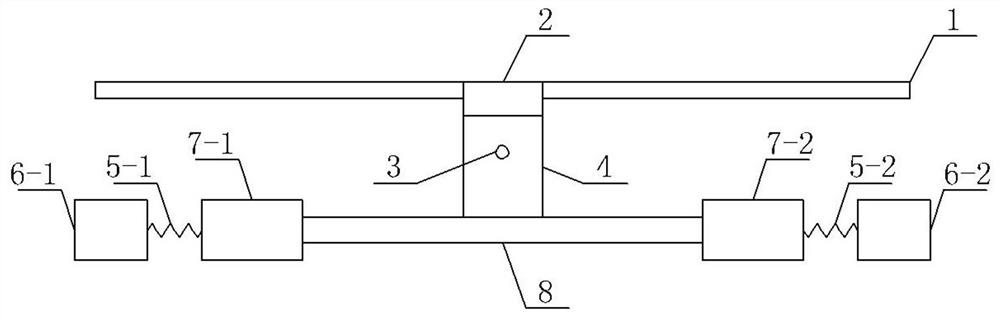

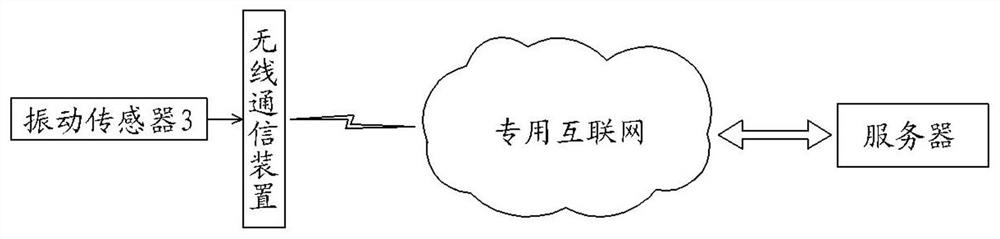

[0043] Such as figure 1 and figure 2 As shown, the present invention discloses a self-adjusting anti-vibration hammer with real-time monitoring, which includes a connecting piece used to connect with the wire 1, a main hammer head used to prevent the wire 1 from vibrating, and an auxiliary hammer head used to prevent the wire 1 from vibrating , a telescopic piece for connecting the main hammer head and the auxiliary hammer head, a vibration sensor 3 and a wireless communication device for obtaining the vibration information of the wire 1, the connecting piece includes a line clamp 2, a connecting body 4 and a steel strand connected in sequence 8. The main hammer head includes a structurally symmetrical first main hammer head 7-1 and a second main hammer head 7-2, and the auxiliary hammer head includes a structurally symmetrical first auxiliary hammer head 6-1 and a second auxiliary hammer head The hammer head 6-2, the telescopic member includes a first spring 5-1 and a secon...

Embodiment 2

[0051] Embodiment 2 is different from Embodiment 1 in that it also includes a controller, a motion sensor for obtaining the motion of the auxiliary hammerhead relative to the main hammerhead, and an acquisition module running on the controller. The motion sensor and the controller Connect and communicate with the collection module, which is used by the motion sensor to obtain the motion information of the position change of the auxiliary hammer head relative to the main hammer head and send it to the controller. The controller receives the motion information from the motion sensor and forwards it to the vibration sensor. The vibration sensor After receiving the motion information from the controller, measuring and obtaining the vibration information of the conductor, the vibration sensor sends the vibration information of the conductor to the communication device.

[0052] Such as Figure 3 ~ Figure 5 As shown, the present invention discloses a self-adjusting anti-vibration ha...

Embodiment 3

[0062] Embodiment 3 is different from Embodiment 2 in that the motion sensor is an infrared proximity switch.

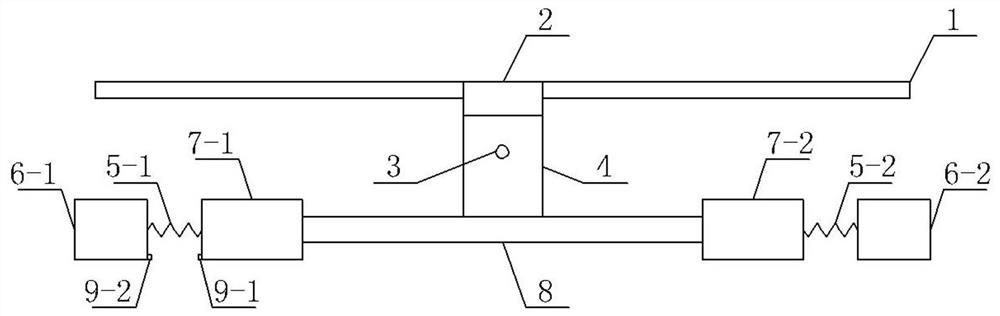

[0063] Such as Figure 6 and Figure 7 As shown, the present invention discloses a self-adjusting anti-vibration hammer with real-time monitoring, which includes a connecting piece used to connect with the wire 1, a main hammer head used to prevent the wire 1 from vibrating, and an auxiliary hammer head used to prevent the wire 1 from vibrating , a telescopic part for connecting the main hammer head and the auxiliary hammer head, a controller, a motion sensor for obtaining the movement of the auxiliary hammer head relative to the main hammer head, a vibration sensor 3 and a wireless communication device for obtaining vibration information of the wire 1, and The acquisition module running on the controller, the connecting part includes the wire clip 2, the connecting body 4 and the steel strand 8 connected in sequence, and the main hammer head includes the first main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com