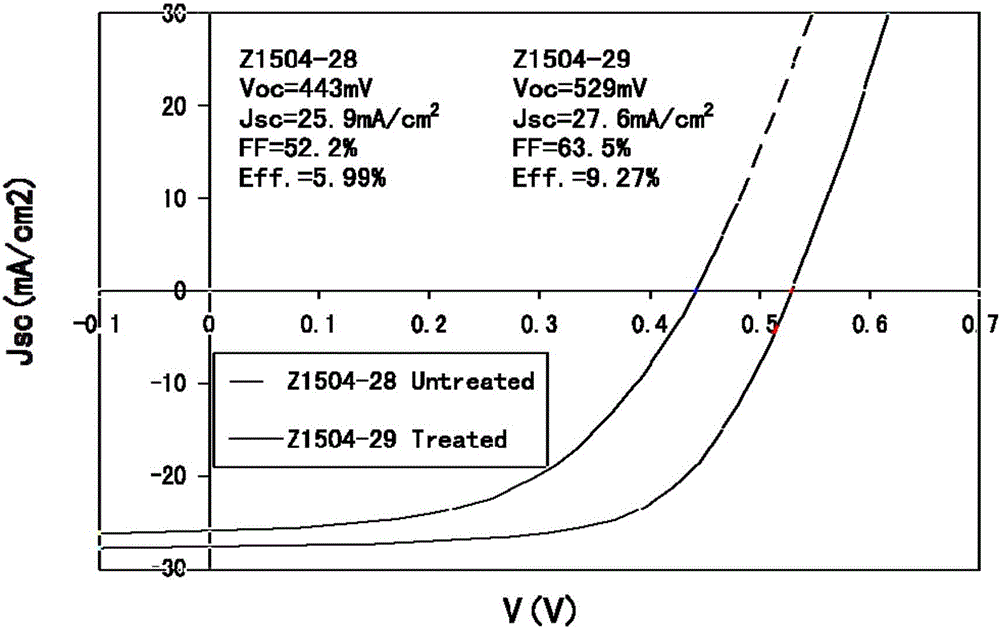

Treating agent after film formation of photoelectric absorption conversion layer of CIGS thin-film solar cell and use method thereof

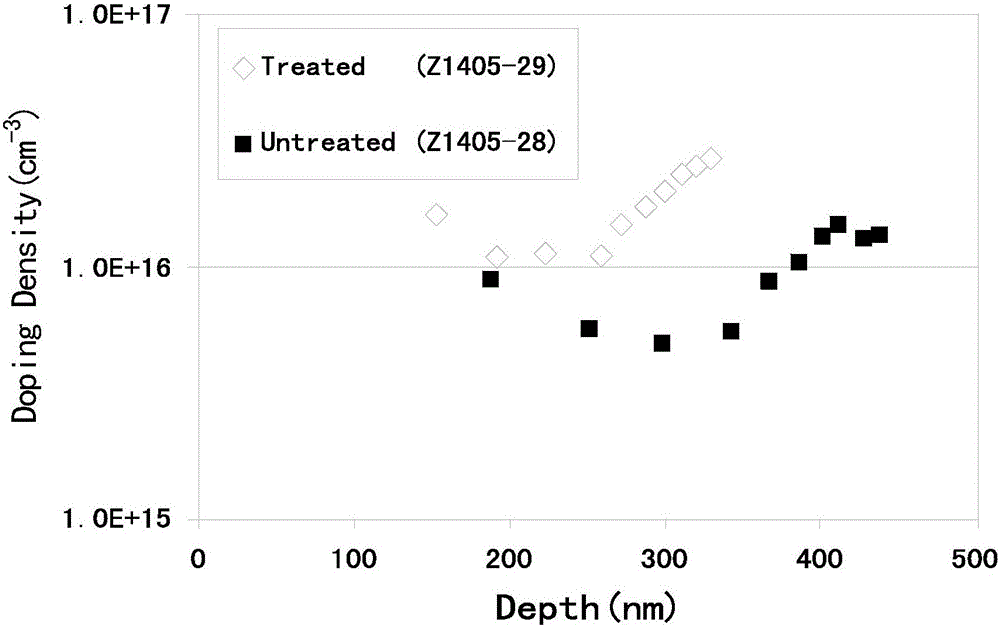

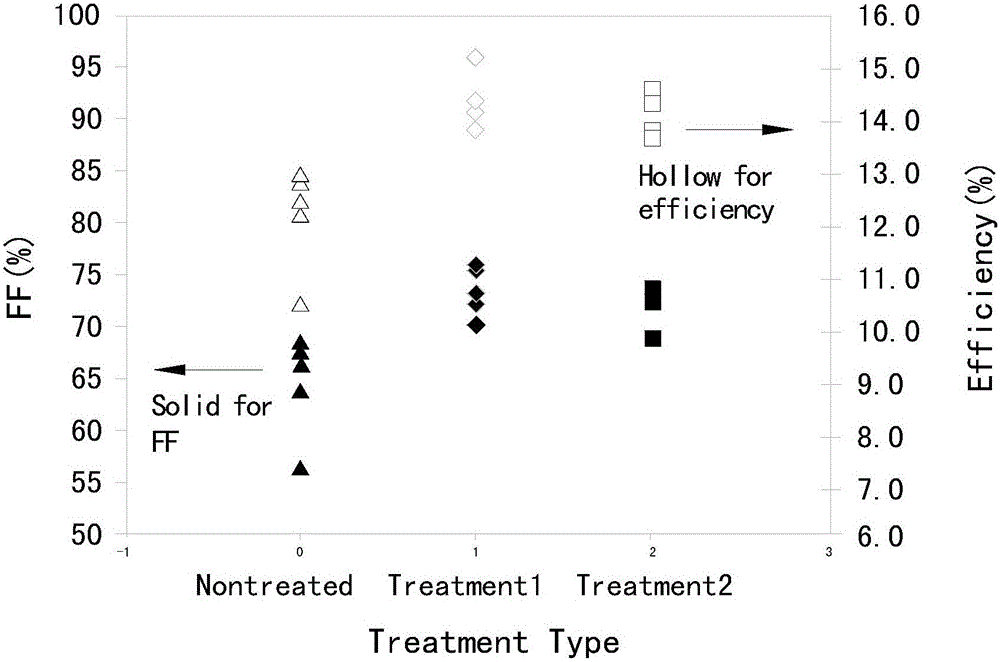

A solar cell, copper indium gallium selenide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems affecting the photoelectric conversion efficiency of solar cells, the difficulty of industrialized production of semiconductor thin films, and the aging of thin films, and achieve photoelectric absorption conversion conversion rate. High, easy to obtain, strong anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0012] The treatment agent for the photoelectric absorption conversion layer of the copper indium gallium selenide thin film solar cell provided in this embodiment is composed of the following components: water, sodium hydroxide, potassium hydroxide, ferric chloride, thiourea, ammonium hydroxide , The molar ratio of each component in the treatment agent per liter is: sodium hydroxide 0.5M, potassium hydroxide 0.35M, ferric chloride 0.35M, thiourea 0.75M, ammonium hydroxide 1.2M, and the rest is water. The preparation process of the treatment agent is as follows: uniformly mix the raw materials of the above components.

[0013] Treat the film-formed copper indium gallium selenide photoelectric absorption conversion layer of the solar cell with the above treatment agent, and the specific steps are as follows:

[0014] 1. Stir and heat the treatment agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com