Manufacturing method of curved screen glass protective film

A glass protective film and a production method technology, which are applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems that the tempered glass protective film cannot be freely pasted, freely bent and folded, and achieve super scratch resistance, The method and steps are reasonable and the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

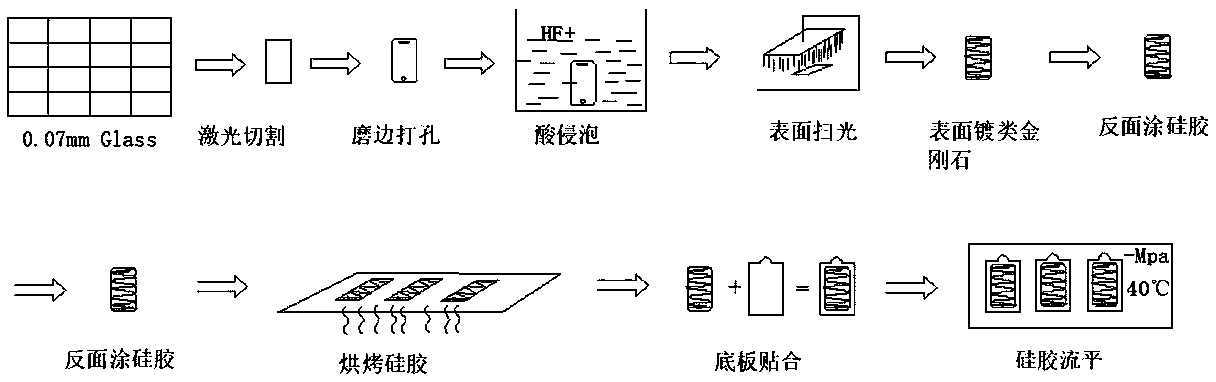

[0024] A method for manufacturing a curved screen glass protective film, the specific steps are as follows:

[0025] Step 1: Cut and edge the 0.07mm thick glass into any mobile phone screen size we need;

[0026] Step 2, soaking the glass after edging in an acidic solution for 10 minutes, the acidic solution is a mixture of 12% hydrofluoric acid solution and 16% nitric acid solution with a mass fraction of 1:2.7;

[0027] Step 3, sweeping the surface of the soaked glass;

[0028] Step 4, electroplating a layer of thin film on the front of the glass after sweeping to obtain coated glass;

[0029] Step five, evenly apply silica gel on the reverse side of the coated glass (that is, the side without the coating film), and then dry it at low temperature to obtain a semi-finished product;

[0030] Step 6: Paste the bottom plate on the side of the semi-finished product coated with silica gel, and then perform degassing and leveling treatment of the silica gel to obtain the finished...

Embodiment 2

[0032] A method for manufacturing a curved screen glass protective film, the specific steps are as follows:

[0033] Step 1: Laser cut and edge the glass into any mobile phone screen size we need, and then punch holes;

[0034] Step 2, putting the glass after edging and drilling into an acidic solution and soaking for 10 minutes, the acidic solution is a mixture of hydrofluoric acid solution with a mass fraction of 13% and a nitric acid solution with a mass fraction of 18% in a mass ratio of 1:3.2 mixture;

[0035] Step 3, sweeping the surface of the soaked glass with a polishing carpet;

[0036] Step 4, electroplating a layer of thin film on the front of the glass after sweeping to obtain coated glass;

[0037] Step five, evenly apply silica gel on the reverse side of the coated glass (that is, the side without the coating film), and then dry it at low temperature to obtain a semi-finished product;

[0038] Step 6: Paste the bottom plate on the side of the semi-finished pr...

Embodiment 3

[0040] A method for manufacturing a curved screen glass protective film, the specific steps are as follows:

[0041] Step 1: Cut and edge the 0.07mm thick glass into any mobile phone screen size we need;

[0042] Step 2, soaking the glass after edging in an acidic solution for 15 minutes, the acidic solution is a mixture of 14% hydrofluoric acid solution and 20% nitric acid solution with a mass fraction of 1:3.6;

[0043] Step 3, sweeping the surface of the soaked glass;

[0044] Step 4, electroplating a layer of diamond-like carbon film on the front of the glass after sweeping, the thickness of the film is 0.03mm, to obtain coated glass;

[0045] Step 5: Apply silica gel evenly on the reverse side of the coated glass (that is, the side without the coating film), and then dry it at low temperature to obtain a semi-finished product, the thickness of which should not exceed 1mm;

[0046] Step 6: Paste the bottom plate on the side of the semi-finished product coated with silica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com