Method for cleaning first mirror in situ through radio frequency plasma

A technology of radio frequency plasma and in-situ cleaning, which is applied in cleaning methods and appliances, chemical instruments and methods, and reduction of greenhouse gases, etc., can solve problems such as tokamak ultra-high vacuum that have not yet been realized, and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

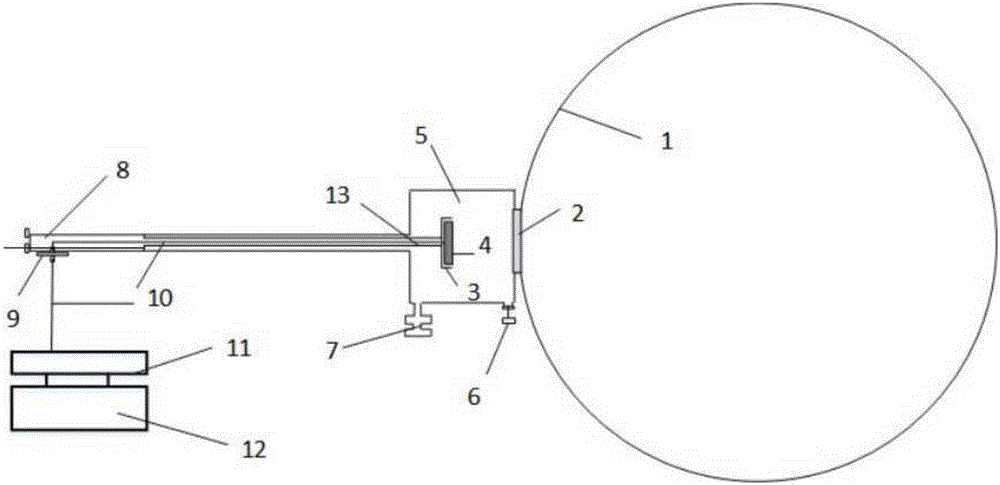

[0027] A method for cleaning the first mirror in situ with radio frequency plasma, characterized in that it comprises the following steps:

[0028] Step A: Install the first mirror sample to be cleaned on the movable structure in the sample exchange chamber, and the shielding end is connected to it. At the same time, the first mirror sample to be cleaned and the shielding end connected to it are connected to the sample exchange chamber through a coaxial cable. An outdoor radio frequency power supply, the radio frequency power supply is also connected with a radio frequency matching device;

[0029] Step B: The sample exchange chamber is connected to the vacuum chamber of the tokamak device through a valve, and an independent vacuum pump group composed of a molecular pump and a mechanical pump and a flange are also arranged on it;

[0030] Step C: Vacuum the sample exchange chamber to 5×10 with a vacuum pump group -5 Below Pa, open the valve, push the first mirror sample to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com