Technology of using asbestos tailings to produce silicon-calcium-magnesium-potassium fertilizer

A technology of silicon calcium magnesium potassium fertilizer and asbestos tailings, applied in the direction of magnesium fertilizer, potassium fertilizer, application, etc., to achieve reasonable steps and reduce environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

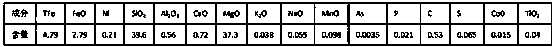

Image

Examples

Embodiment Construction

[0018] Take the actual production in Yitunbulak Town, Ruoqiang County, Xinjiang as an example:

[0019] A kind of technology that utilizes asbestos tailings to produce silicon-calcium-magnesium-potassium fertilizer:

[0020] 1) First use a cone crusher to crush the serpentine raw material to about 3 cm, and then add it to a ball mill for ball milling. The ball milling time is 30-40 minutes, and the particle size of the serpentine is controlled at about 250 mesh;

[0021] 2) Add KCl particles into the ball mill, the addition amount is one-ninth of the serpentine mass, and continue the ball milling operation for 30 minutes;

[0022] 3) When the particle size of the material in the ball mill is greater than 300 mesh, start to discharge the material, and discharge the material to the winnowing machine;

[0023] 4) The winnowing machine adopts 6kg pressure to winnow the powder;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com