Installing method of dry quenching fire automatic alarm system

A technology for automatic fire alarm and system installation, which is used in furnace safety devices, coke ovens, and coke cooling. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

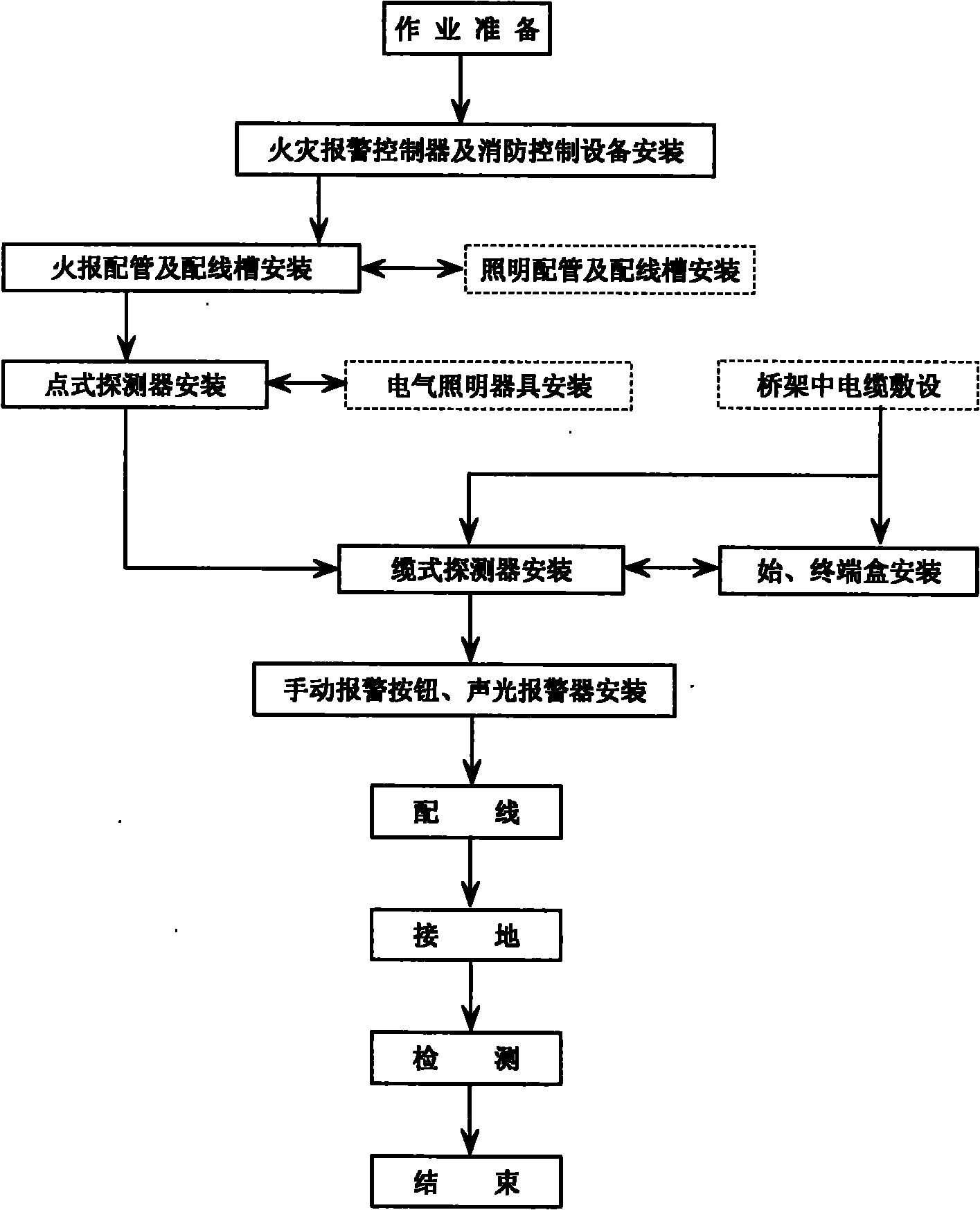

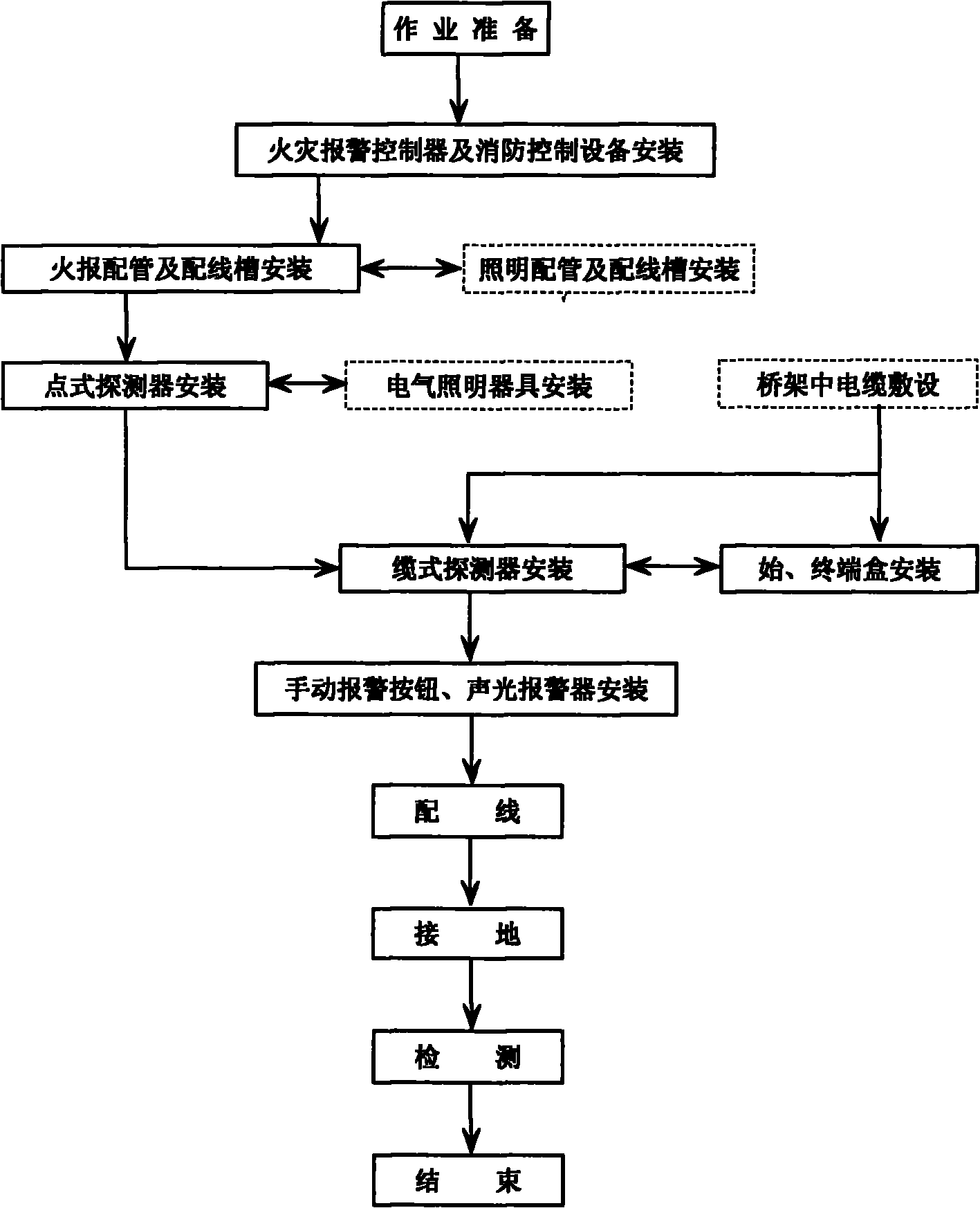

[0018] Now it is necessary to install an automatic fire alarm system in the CDQ equipment. The installation consists of job preparation, installation of fire alarm controller, installation of fire control equipment, installation of fire alarm piping and wiring trough, installation of lighting piping and wiring trough, installation of point type Detectors, installation of electrical lighting equipment, laying cables in the bridge, installation of cable detectors, installation of start-end boxes and end-boxes, installation of manual alarm buttons and sound and light alarms, wiring, grounding and monitoring are carried out in sequence. The specific operation process is as figure 1 shown.

[0019] When preparing for work, the type and specification of insulated wires and cables meet the design requirements, the materials and specifications of metal pipes and pipeline parts meet the design requirements, and non-metallic pipes, closed trunking and accessories are made of non-combust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com