Novel Krah pipe and preparation process thereof

A preparation process and carat tube technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of poor continuity of production process, harsh working environment and high processing cost, achieve light weight, speed up acceptance, and improve resistance to external pressure. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

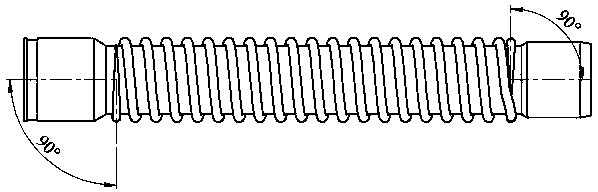

[0028] A new type of carat tube, including a body, wherein the peripheral winding rib structure of the body is wound at a vertical 90-degree angle at the first and last ends, and the first and last ends of the peripheral winding rib structure are tapered structures.

[0029] A new carat tube preparation process, the specific steps are as follows:

[0030] S1, mixing: select qualified raw materials, put the raw materials into the mixing unit according to the ratio, mix them evenly and dry them, the drying time is 30 minutes, and the drying temperature is 40 degrees Celsius;

[0031] S2, extruding: send the dried raw material to the extruder, the barrel temperature of the extruder is 155 degrees Celsius, and the mold temperature of the extruder is 190 degrees Celsius;

[0032] S3, heating: the mold drum is heated by infrared high-frequency through an infrared heating device, and the corrugated pipe is passed through the pipe material, and the molten pipe material is coated on th...

Embodiment 2

[0041] A new type of carat tube, including a body, wherein the peripheral winding rib structure of the body is wound at a vertical 90-degree angle at the first and last ends, and the first and last ends of the peripheral winding rib structure are tapered structures.

[0042] A new carat tube preparation process, the specific steps are as follows:

[0043] S1, mixing: select qualified raw materials, put the raw materials into the mixing unit according to the ratio, mix them evenly and dry them, the drying time is 40 minutes, and the drying temperature is 43 degrees Celsius;

[0044] S2, Extrusion: Send the dried raw materials to the extruder, the barrel temperature of the extruder is 160 degrees Celsius, and the mold temperature of the extruder is 200 degrees Celsius;

[0045] S3, heating: the mold drum is heated by infrared high-frequency through an infrared heating device, and the corrugated pipe is passed through the pipe material, and the molten pipe material is coated on t...

Embodiment 3

[0054] A new type of carat tube, including a body, wherein the peripheral winding rib structure of the body is wound at a vertical 90-degree angle at the first and last ends, and the first and last ends of the peripheral winding rib structure are tapered structures.

[0055] A new carat tube preparation process, the specific steps are as follows:

[0056] S1, mixing: select qualified raw materials, put the raw materials into the mixing unit according to the ratio, mix them evenly and dry them, the drying time is 50 minutes, and the drying temperature is 45 degrees Celsius;

[0057] S2, extruding: send the dried raw material to the extruder, the barrel temperature of the extruder is 165 degrees Celsius, and the mold temperature of the extruder is 210 degrees Celsius;

[0058] S3, heating: the mold drum is heated by infrared high-frequency through an infrared heating device, and the corrugated pipe is passed through the pipe material, and the molten pipe material is coated on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com