Road tank container with saddle structures

A saddle and road technology, applied in the field of liquid tankers, can solve the problems of poor structural strength and stability, and achieve the effects of reducing self-weight and cost, good external pressure resistance and impact resistance, and increasing loading volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

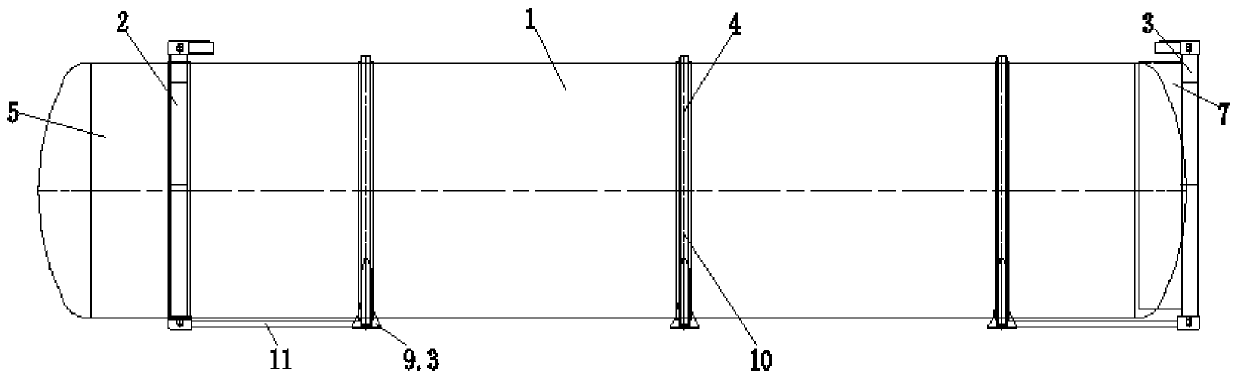

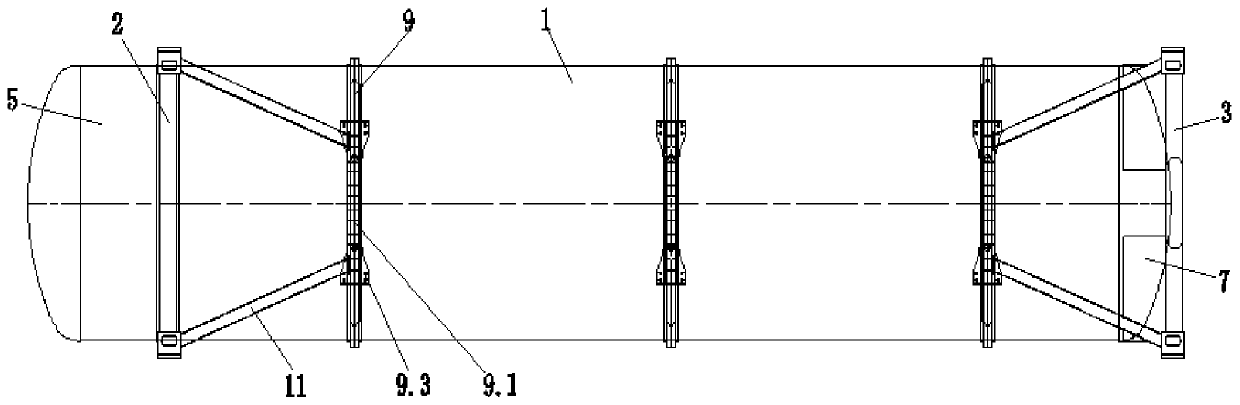

[0029] Such as Figure 1-Figure 5 As shown, a road tank container with a saddle structure includes a tank body 1, a front frame 2, a rear frame 3, and three reinforcement ring structures 4, and the front frame 2 and the rear frame 3 are all carbon steel material. in:

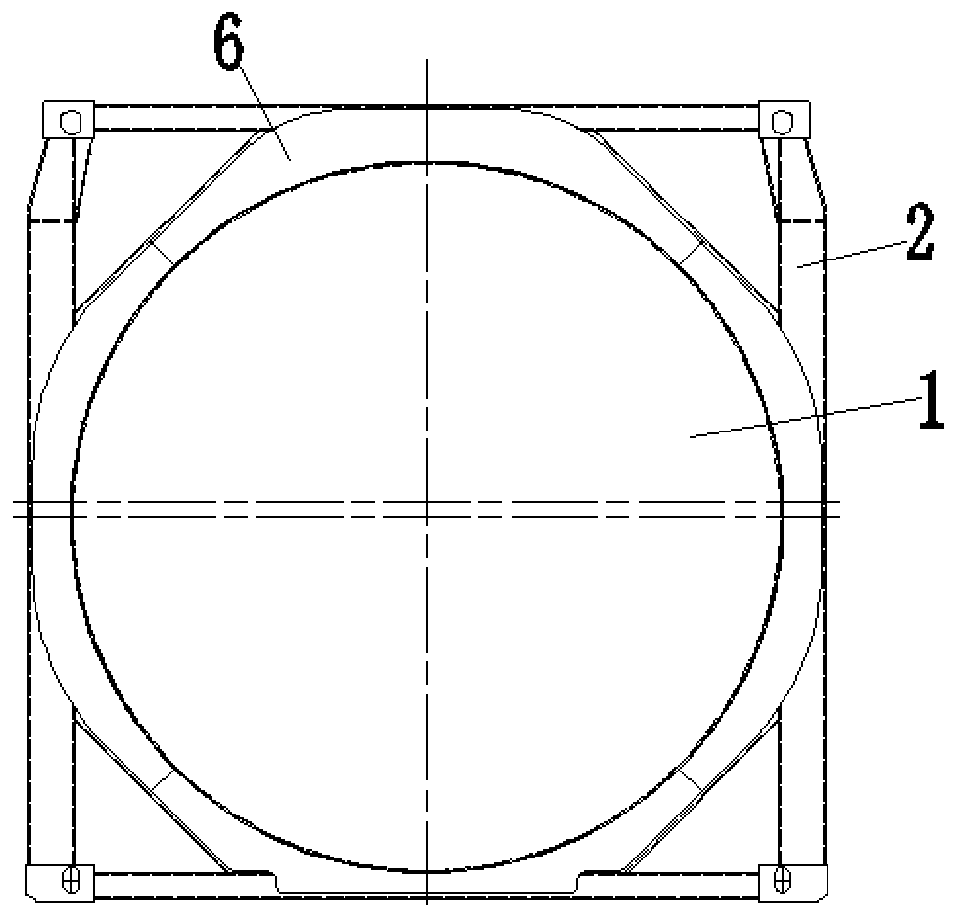

[0030] The front end of the tank body 1 passes through the front end frame 2 to form a front protrusion 5, and the front end frame 2 surrounds the tank body 1, and the circumferential outer wall of the tank body 1 close to the front side or rear side of the front end frame 2 is formed with a circumferential connecting plate 6, The hoop connecting plate 6 is fixedly connected to the front side or the rear side of the frame edge of the front frame 1 .

[0031] The rear end frame 3 is arranged at the axial rear end of the tank body 1, and the frame surface of the rear end frame 3 facing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com