Epoxy resin and silicon resin cured coating and package removing agent and preparation method thereof

A technology of epoxy resin and silicone resin, which is applied in the direction of epoxy resin coating, chemical coating/ink remover, coating, etc., can solve the problems of no peeling and removal methods, etc., and achieve wide use temperature range and low volatility Sexuality and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

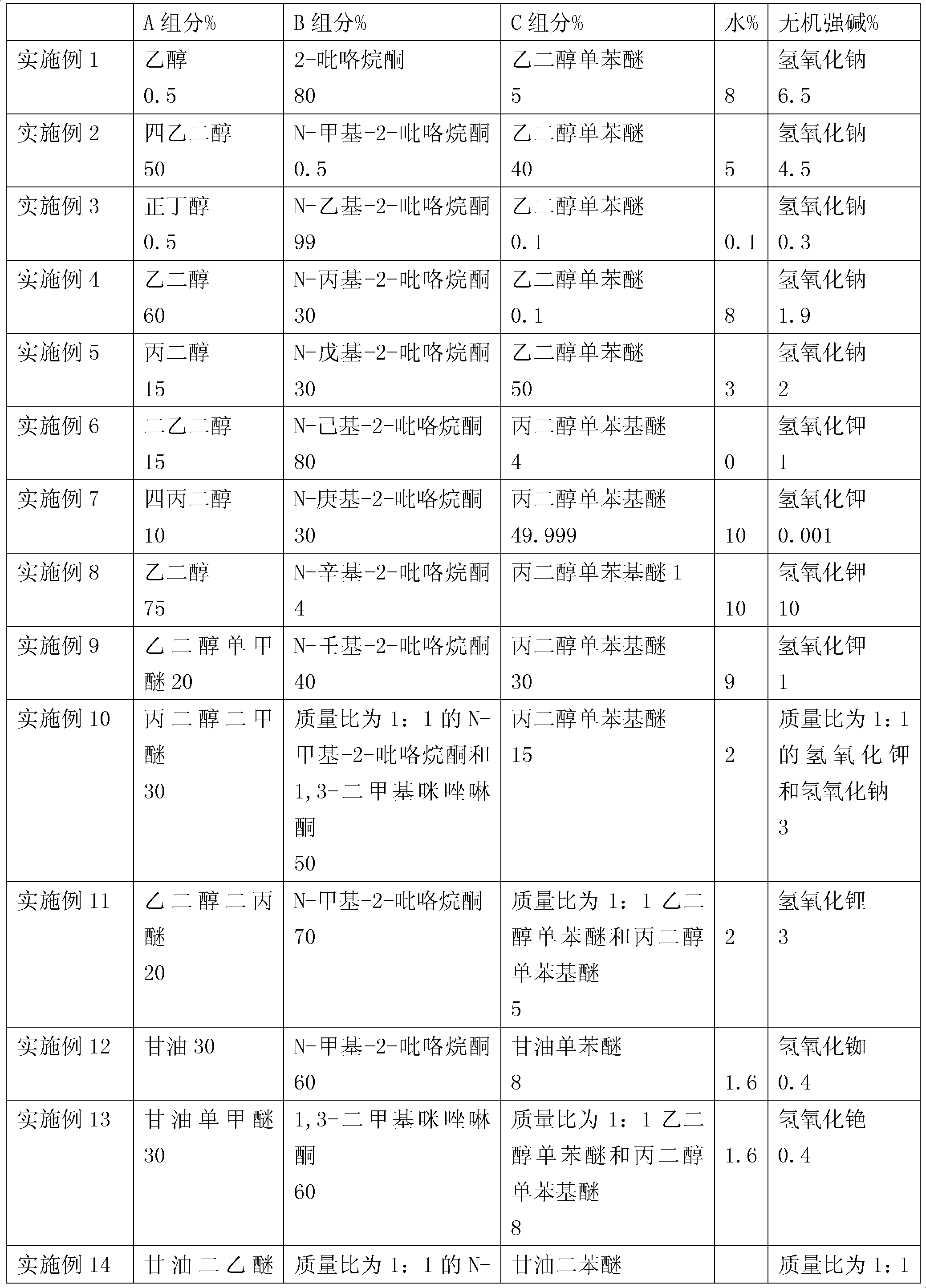

Examples

Embodiment 21

[0050] The preparation method of the remover of epoxy resin and silicone resin cured coating and encapsulation, comprises the steps:

[0051] (1) get each raw material of embodiment 1;

[0052] (2) Mix and stir the raw materials in step (1) evenly to make epoxy resin and silicone resin cured coating and encapsulation remover.

[0053] The raw materials of Examples 2-20 can be prepared by the method of Example 21 into epoxy resin and silicone resin cured coatings and encapsulation removers.

[0054] The said silicone resin of the present invention, its scientific name is polysiloxane resin.

[0055] Remove effect:

experiment example 1

[0057] Immerse the electronic component that needs to remove the cured epoxy resin in the container containing the remover prepared by the formula in Example 20, seal it, and heat it to 50 ° C. When it is observed that the cured epoxy resin has been removed from the electronic component , Take out the electronic components with clips and rinse with water.

experiment example 2

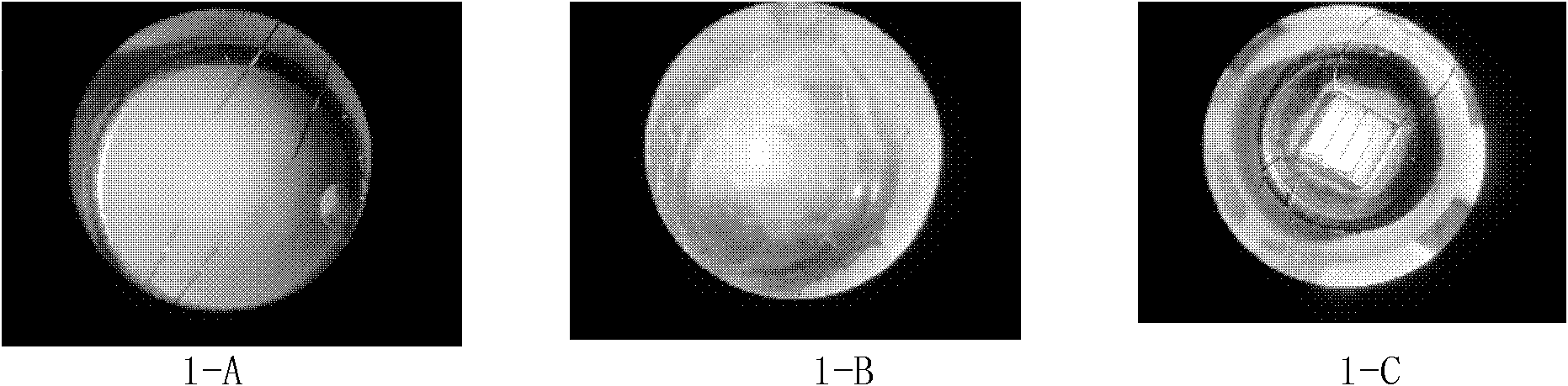

[0059] Take about 100ml of remover (prepared by the formula in Example 9) and put it into a beaker, heat it to 110°C, put it into a silicone rubber (Dow Corning OE-6630, OE-6250) LED sample ( figure 1 middle figure 1 -A), and turn on the stirring, process for 20 minutes, take out the silicone rubber LED sample, rinse it with clean water, the silicone rubber has been partially dissolved (such as figure 1 -B). After the sample was continuously processed for 25 minutes, it was taken out and rinsed with clear water, and the silicone rubber was completely dissolved and peeled off (such as figure 1 -C). It shows that the remover has a good peeling effect on the cured silicone rubber, but the gold wire is intact, the chip is intact, and the substrate has no corrosion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com