Reaction kettle suitable for intermittent mixed acid nitration

A technology of reaction kettle and mixed acid, which is applied to the field of reaction kettles for intermittent nitration of mixed acid, can solve the problems of insufficient stirring of materials, inability to submerge stirring paddles, hidden safety hazards, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

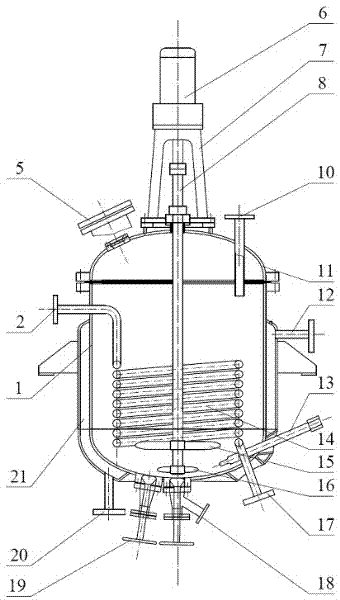

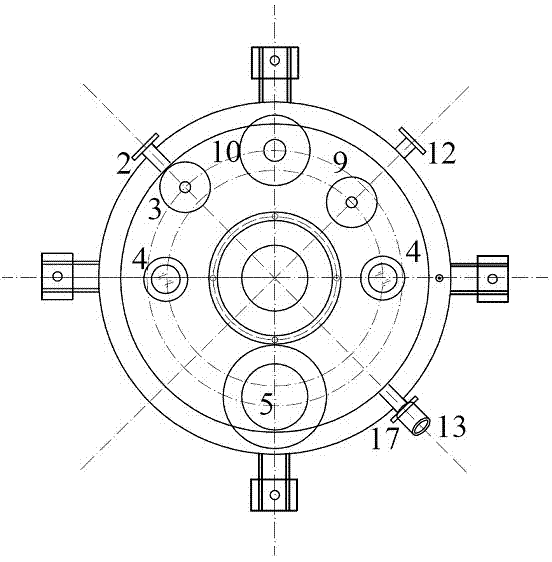

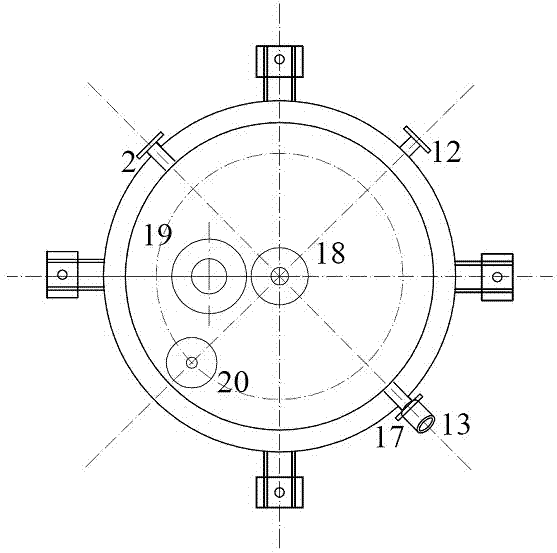

[0019] A 100L reaction kettle suitable for intermittent nitration of mixed acids has an inner diameter of 500mm and a height-to-diameter ratio of the kettle body 1 of 1.

[0020] The reactor and all components in the reactor are made of stainless steel 316L to reduce the corrosion of the reactor body by the mixed acid.

[0021] Combined with the characteristics of mixed acid nitration reaction, a double-layer stirring paddle was designed for the reactor. In the initial stage, nitric-sulfur mixed acid needs to be prepared first. The amount of nitric acid in the kettle is small and the liquid level is low. Therefore, a small-diameter auxiliary stirring paddle is added near the inner bottom of the lower head. mix. In the later stage, the material in the kettle increases, and the reaction is accompanied by liquid phase stratification and solid precipitation. Therefore, the main stirring impeller adopts a three-blade propulsion type, which is characterized by a large liquid discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com