Method of constructing enlarged based composite foundation for stirring concrete filling pile

A technology of composite foundation and construction device, which is applied in basic structure engineering, sheet pile wall, earthwork drilling and mining, etc., can solve the problems of low pile bearing capacity, troublesome construction, poor ability to adapt to complex geological conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

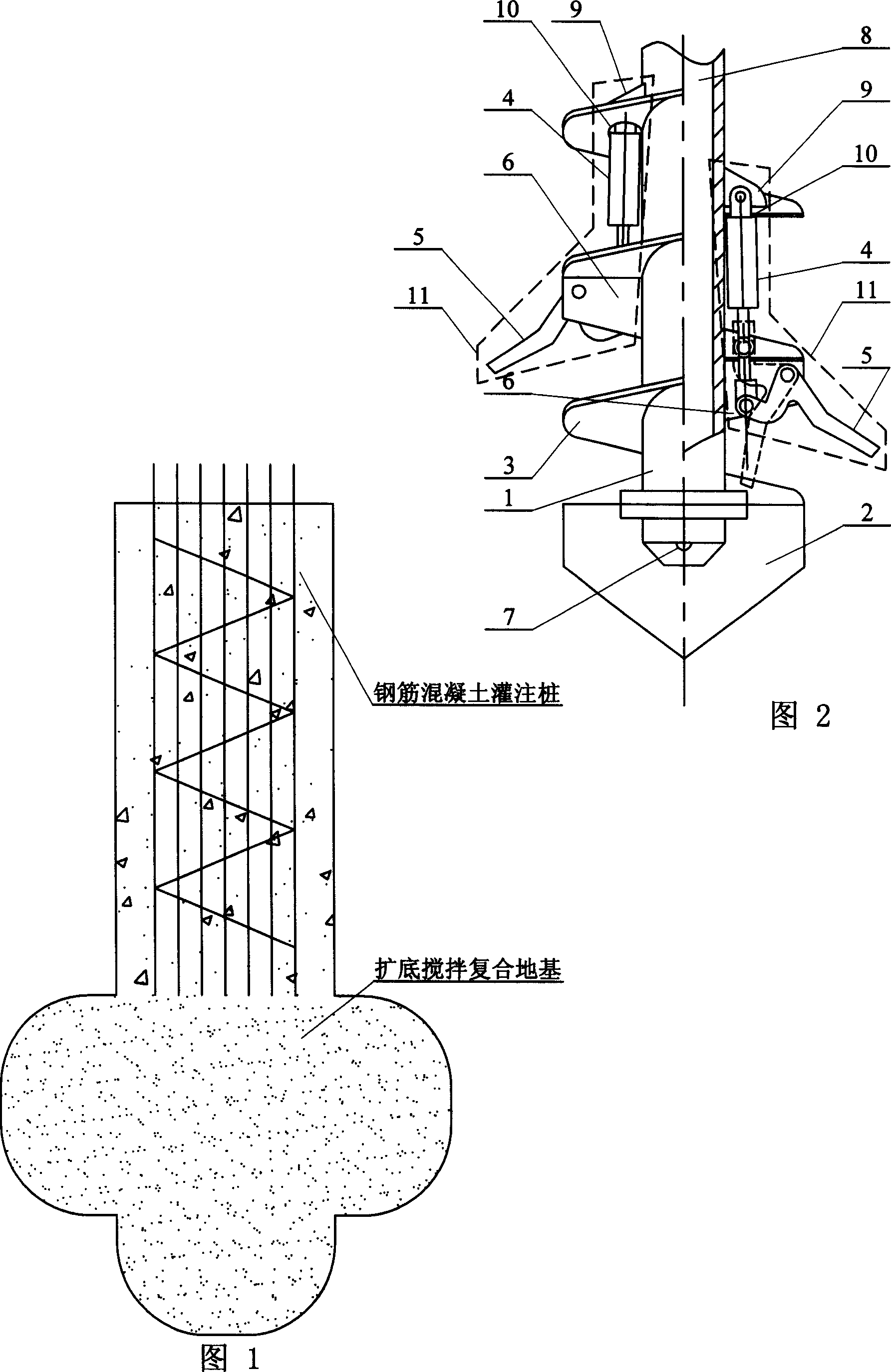

[0005] Specific embodiment one: (referring to Fig. 1-Fig. 2) the construction method of the bottom expansion mixing composite foundation of the present embodiment is: when the drilling tool is drilled to the design depth, the mixing head on the side of the lower end of the drilling tool is stretched out and is driven by the drilling tool The grouting hole at the bottom sprays cement slurry or cement mortar to the bottom of the hole, and the drilling tool is lifted up while rotating, and the soil scraped off after the bottom of the hole is enlarged by the mixing head is stirred and mixed evenly with the cement slurry or cement mortar to form a bottom expansion mixing compound For the foundation, when the drilling tool is lifted to the design height (that is, the design thickness of the composite foundation), the mixing head is retracted into the drilling tool, and the bottom expansion and mixing composite foundation is obtained. The construction device for bottom expansion and m...

specific Embodiment approach 2

[0006] Specific embodiment two: (see Fig. 2) the difference between this embodiment and the bottom expanding and stirring composite foundation device in specific embodiment one is that a telescopic stirring head is added on the drill pipe 1 on the other side of the telescopic stirring head 11 11. Two telescopic mixing heads 11 are fixed on both sides of the drill pipe 1 in parallel. Other components and connections are the same as those of the bottom expansion and mixing composite foundation construction device in the first embodiment.

[0007] The invention can normally carry out pile type constructions such as grouting piles, superfluid piles, CFG piles, and mortar-pressing piles through the grouting hole at the bottom center of the drill pipe on the bottom-expanding and stirring composite foundation. If it is a pile type poured after the hole is completed, such as mud wall expansion, manual digging, etc., put the construction device into the formed hole, and extend the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com