Internal heating and united stirring type isothermal quenching salt-bath device

A kind of isothermal quenching and salt bath technology, applied in quenching device, heat treatment equipment, heat treatment process control and other directions, can solve the problems of not achieving improved performance of isothermal quenching, difference in workpiece performance, low toughness, etc., to increase stability, reduce The effect of temperature fluctuation and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

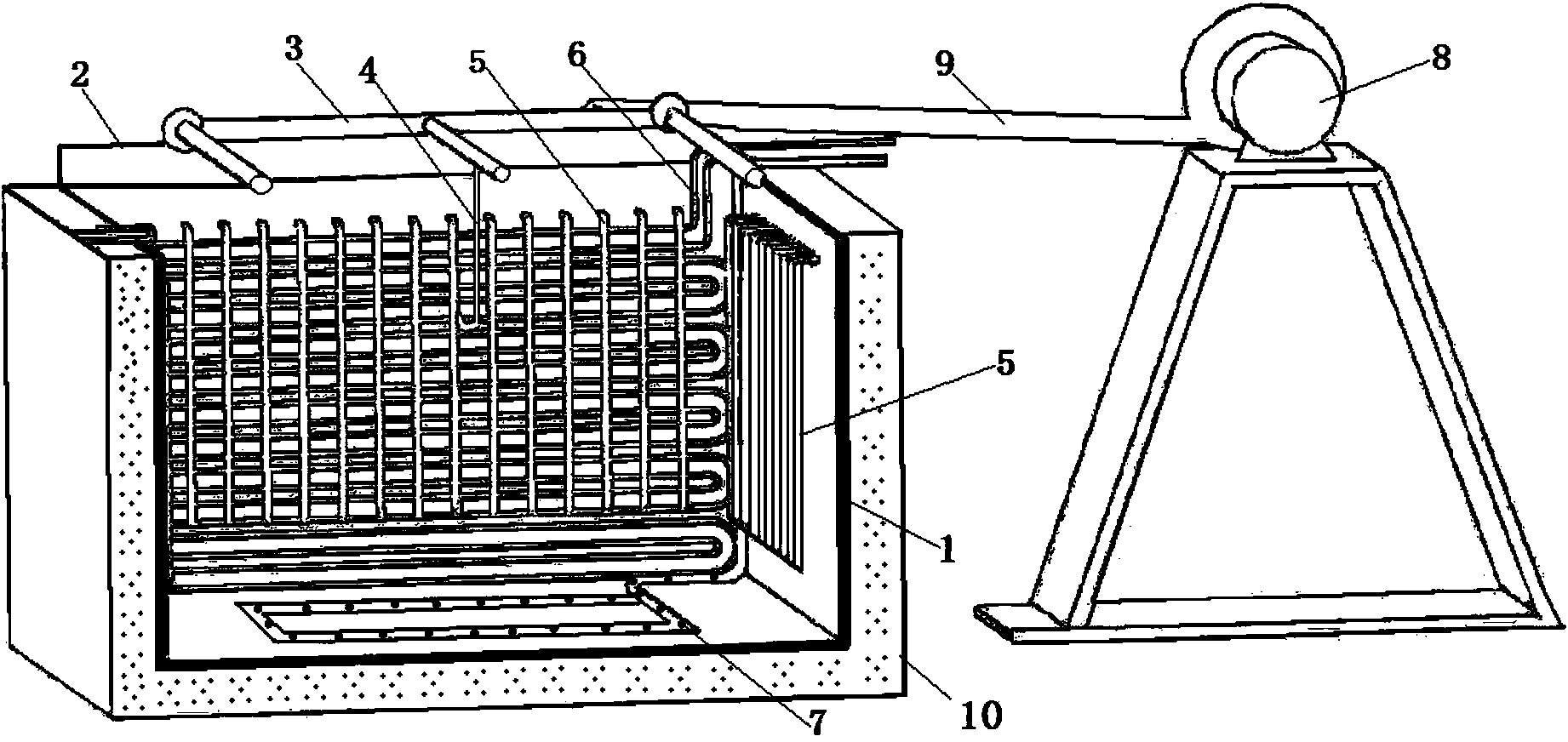

[0018] The structure of the internal heat combined stirring isothermal quenching salt bath device provided by the application is as follows: figure 1 As shown, the salt bath tank is in the shape of a cuboid and is made up of a stainless steel liner 1 and an insulating layer 10. The thickness of the stainless steel liner 1 is 5-8mm. The outside of the stainless steel liner 1 is provided with an insulating layer 10, and the insulating layer 10 has a thickness of 15 to 20 cm, and a workpiece rack for placing workpieces is provided in the salt bath. Described salt bath tank is provided with inner heating system, cooling system, combined stirring system and temperature control system, and wherein inner heating system is heating rod 5, and described heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com