External heating device and oil-water separator

A technology of oil-water separator and heating device, which is applied in the direction of charging system, machine/engine, engine components, etc. It can solve the problems of poor fluidity of diesel oil, inability to supply diesel oil to the engine, and affect the normal operation of the car, so as to reduce heat loss. , Easy to install and popularize, improve heating efficiency and heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

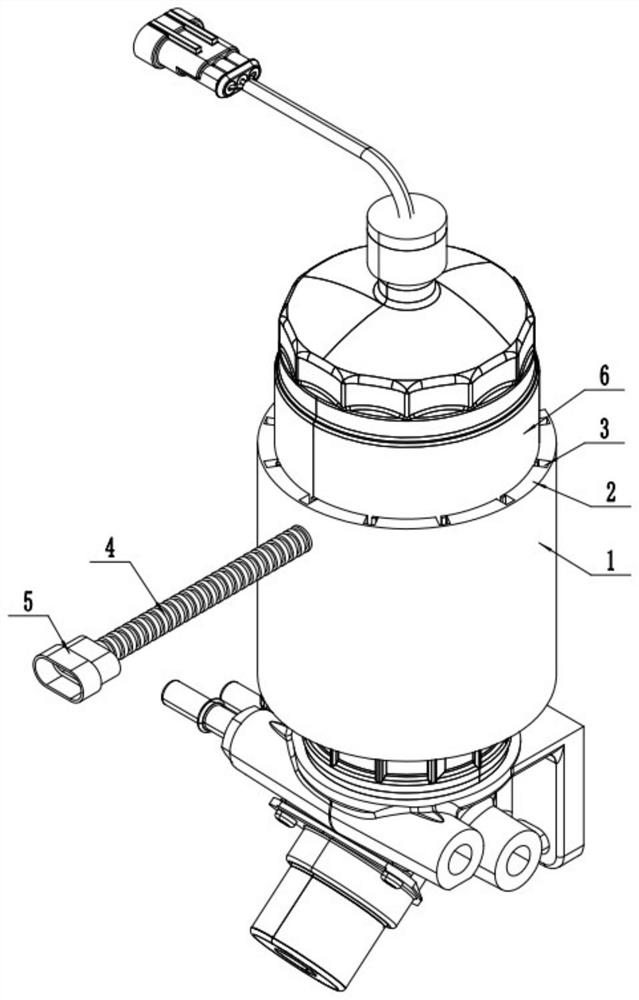

[0018] Please refer to figure 1 , an external heating device, including a heating body 1, the heating body 1 includes an inner side wall and an outer side wall, a plurality of rib grooves 3 are arranged on the inner side wall, and a heating convex surface 2 is arranged between adjacent rib grooves 3 , the heating convex surface 2 is a sealed cavity, the heating convex surface 2 is provided with a heating element, the outer wall of the heating convex surface 2 is provided with an insulating layer, and the heating element is connected to a power supply. The inner wall and the outer wall can not only play a protective role, but also keep the heating element in a fixed shape, which is convenient for installation. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com