Stirring device for glue used for electronic processing

A technology of stirring device and glue, applied in the directions of transportation and packaging, dissolving, mixer, etc., can solve the problems of insufficient stirring degree and limited stirring range, and achieve the effect of improving stirring effect, full stirring and promoting turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

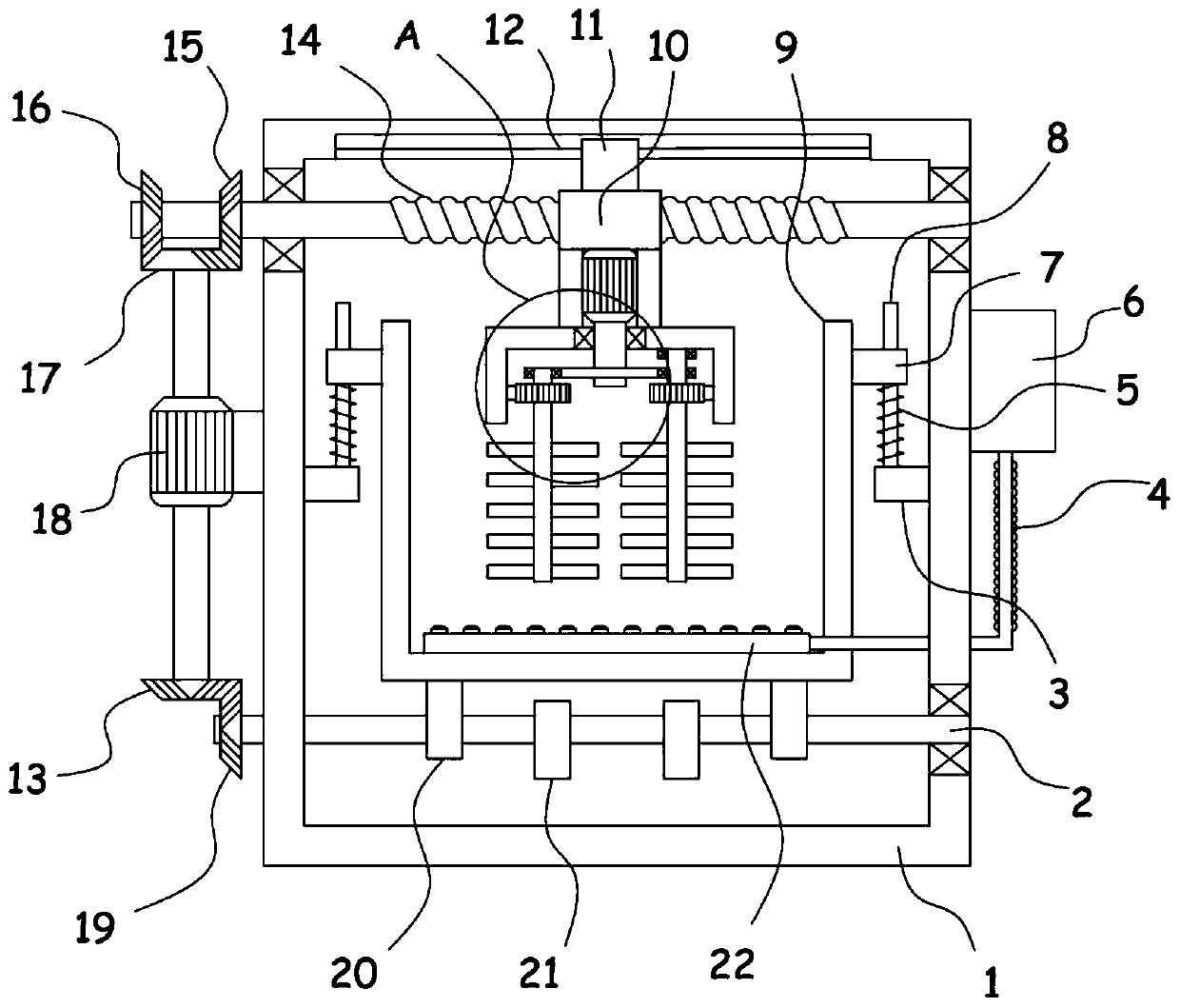

[0025] see Figure 1-4 , a stirring device for electronic processing glue, including a fixed frame 1, a stirring tank 9 is provided in the fixed frame 1, and a stirring mechanism for stirring the glue inside the stirring tank 9 driven by a lateral translation mechanism is provided in the fixed frame 1 , the fixed frame 1 is fixed with a biaxial motor 18, and the biaxial motor 18 is connected with a reversing mechanism that drives the threaded rod 14 forward and reverse. the push mechanism.

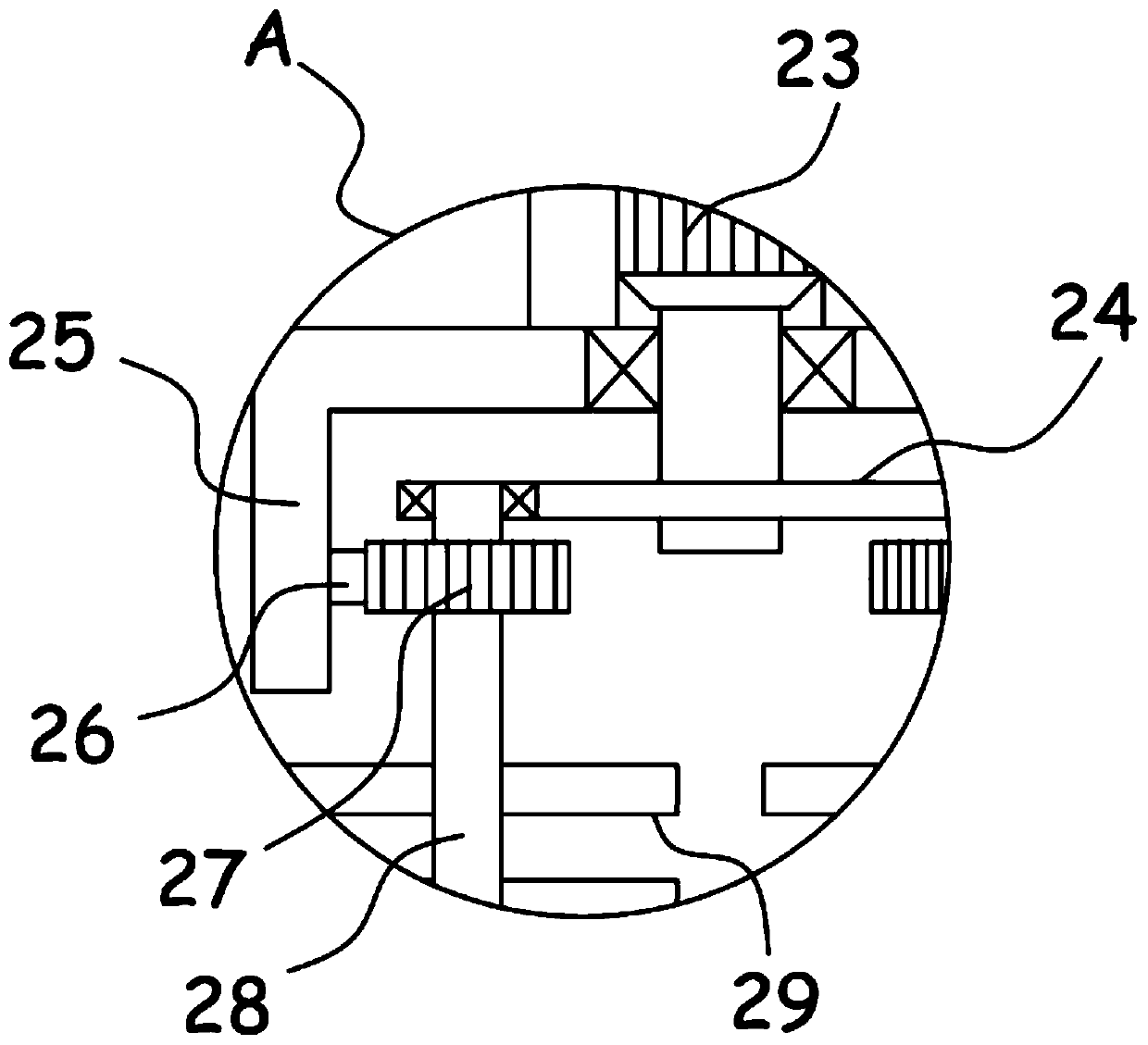

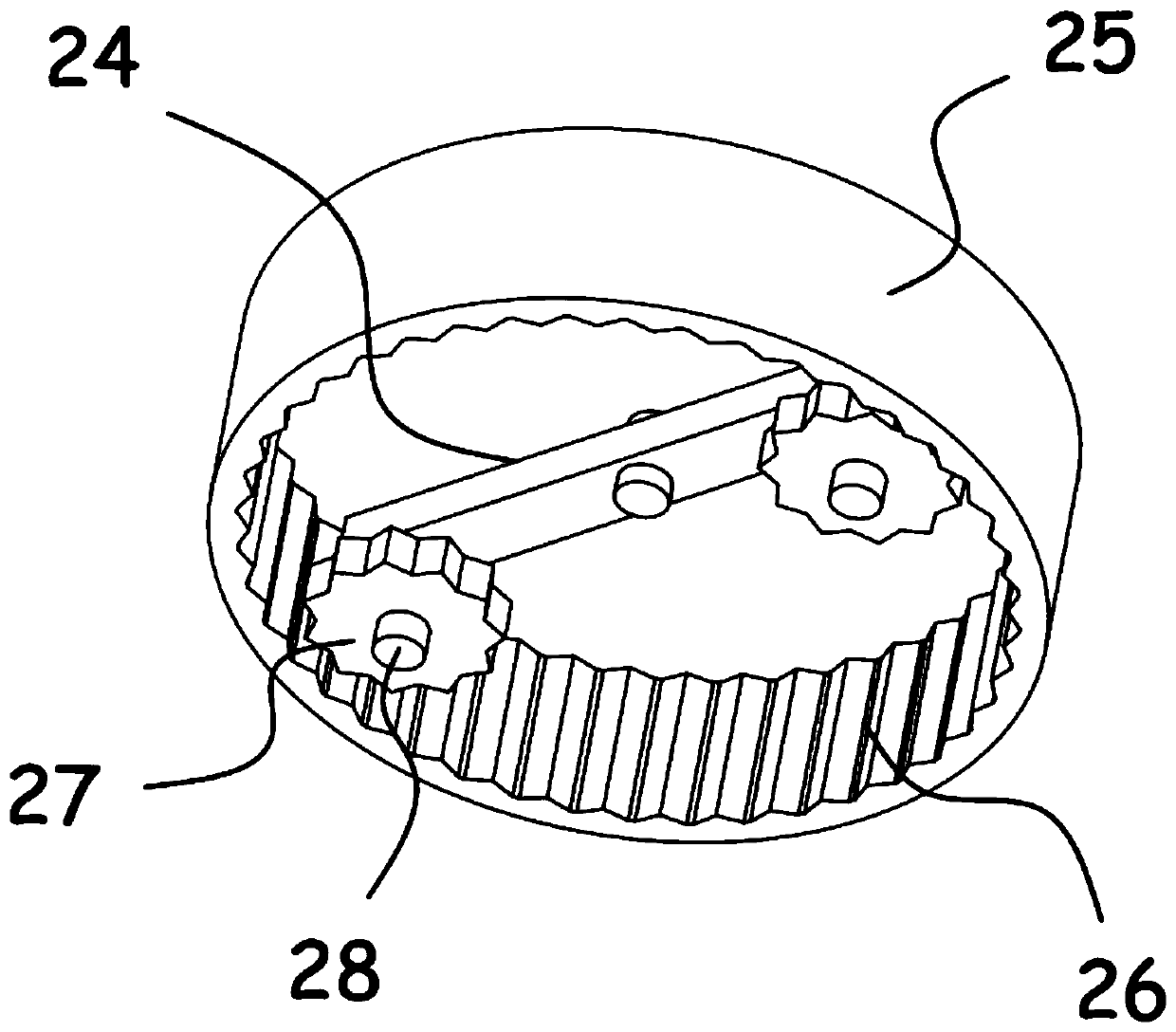

[0026] The stirring tank 9 provided by the device is used to store the glue to be stirred, and the glue inside the stirring tank 9 is rotated and stirred by the stirring mechanism provided. Specifically, the stirring mechanism includes a fixed mount 25, and the fixed mount 25 is rotated and installed with The connection plate 24 driven by the driving motor 23, the bottom of the connection plate 24 is vertically equipped with a transmission shaft 28, and the side walls of the transmission ...

Embodiment 2

[0032] In order to further improve the stirring effect of the glue, on the basis of Embodiment 1, in addition, this device is also provided with a reversing mechanism, which includes an incomplete bevel gear 17 coaxially fixed with an output shaft of the biaxial motor 18, and the incomplete The bevel gear 17 is alternately engaged with a driven bevel gear I15 and a driven bevel gear II16 coaxially fixed with the threaded rod 14 .

[0033] The biaxial motor 18 can drive the incomplete bevel gear 17 to rotate, and the incomplete bevel gear 17 is alternately meshed with the driven bevel gear I15 and the driven bevel gear I15, thereby realizing the alternating forward and reverse rotation of the threaded rod 14, that is, the threaded sleeve The block 10 can drive the stirring mechanism to move horizontally and reciprocate automatically, which greatly improves the convenience of operation and the stirring efficiency of the glue.

[0034] Further, the device is also provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com