Molten glass stirring device

A technology of molten glass and stirring device, which is applied in mixers with rotating stirring device, glass production, glass molding, etc., which can solve problems such as difficulty in obtaining molten glass homogeneity, and achieve high transparency and excellent homogeneity , Excellent effect of homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

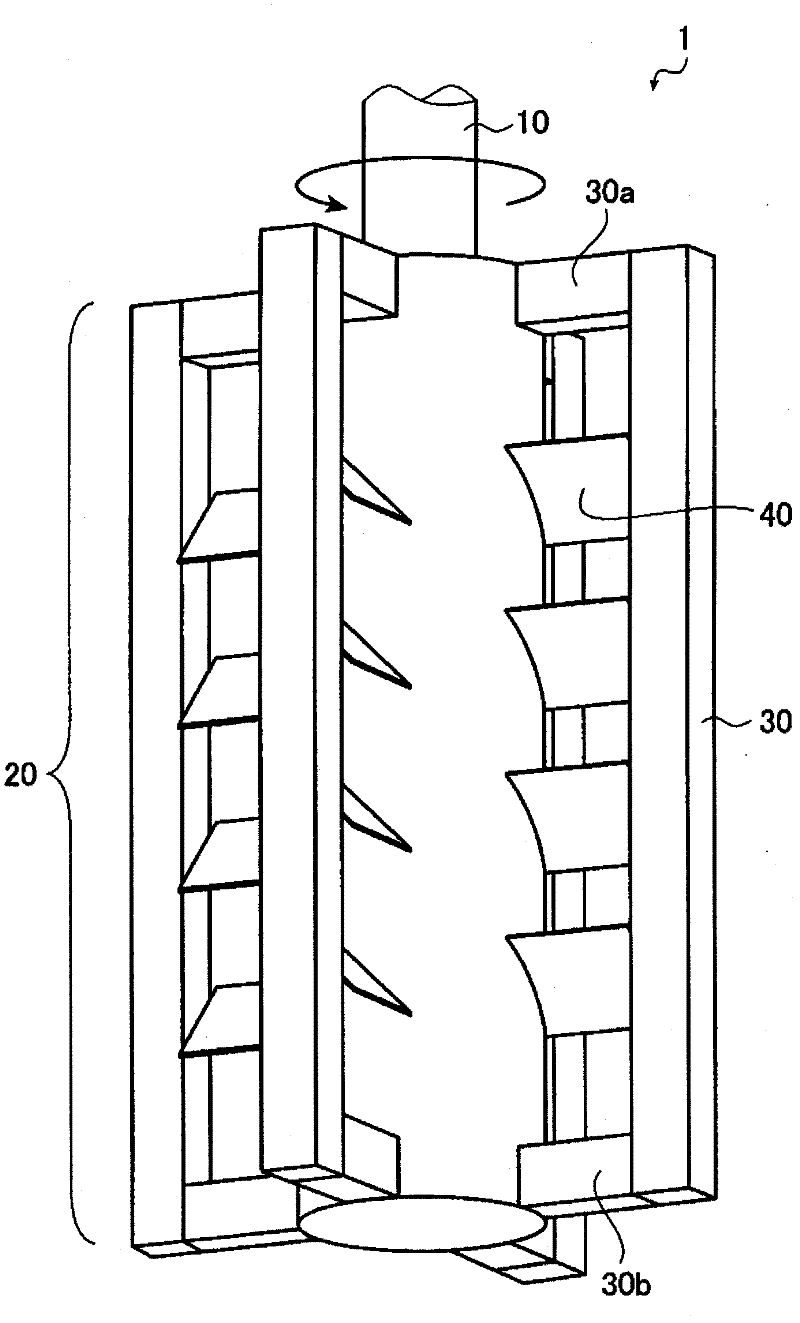

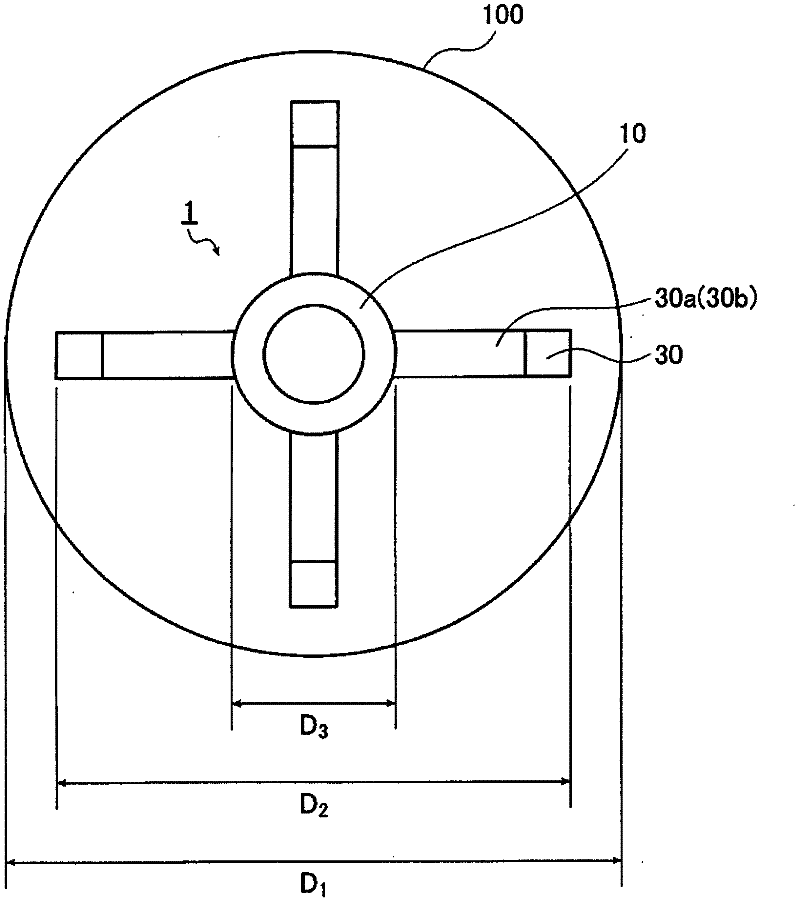

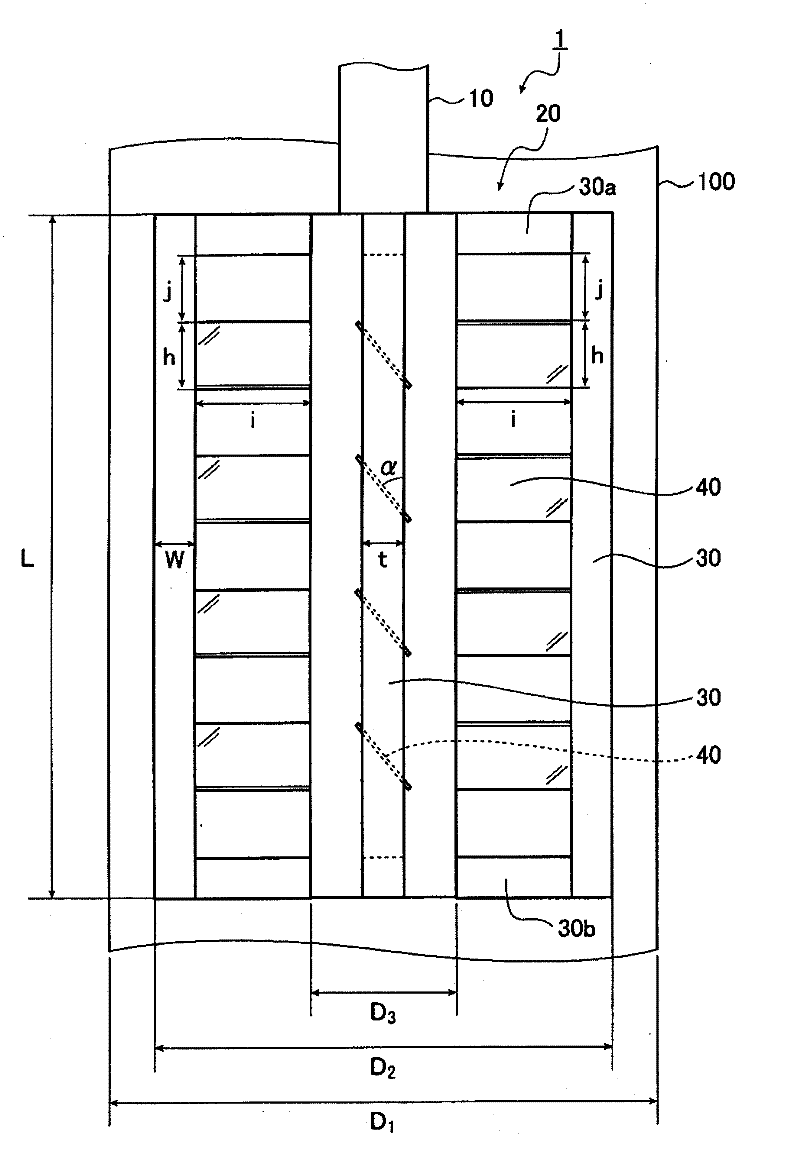

[0096] pair Figure 1~3 The flow of the fluid when the shown glass stirring device 1 of the present invention was inserted into the delivery pipe and stirred was evaluated. The dimensions of each part of the glass stirring device are as follows.

[0097] The maximum diameter D of the outer edge of the stirring part 20 2 : 38mm

[0098] The diameter of the central shaft 10 (the part that constitutes the stirring part 20) D 3 : 10mm

[0099] The length L of the longitudinal stirring blade 30: 60mm

[0100] Width W of longitudinal stirring blade 30: 3.8mm

[0101] Thickness t of longitudinal stirring blade 30: 3.8mm

[0102] The inclination angle α of the transverse stirring blade 40 relative to the central axis 10: 60 degrees

[0103] The length i of the horizontal stirring blade 40: 10.2mm

[0104] The height h of the horizontal stirring blade 40: 8mm

[0105] Thickness of horizontal stirring blade 40: 2mm

[0106] The area S of the portion where the transverse stirri...

Embodiment 2

[0137] As an example of glass plate production, a glass plate is produced using a glass plate manufacturing apparatus having a glass melting device, a first molten glass delivery pipe, a vacuum degassing device, a second molten glass delivery pipe, and a float forming device. The first and second molten glass delivery pipes are provided with Figure 1~3 The glass stirring device 1 of the present invention is shown.

[0138] Glass raw materials are heated and melted by a glass melting device to obtain molten glass. The molten glass is formed into a glass plate by passing through the first molten glass conveying pipe, the vacuum defoaming device, the second molten glass conveying pipe and the float forming device in sequence. When the molten glass is transported through the first and second molten glass delivery pipes, the glass stirring device of the present invention is used to stir to improve the homogeneity, and the unmelted raw materials are not mixed, and the glass with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com