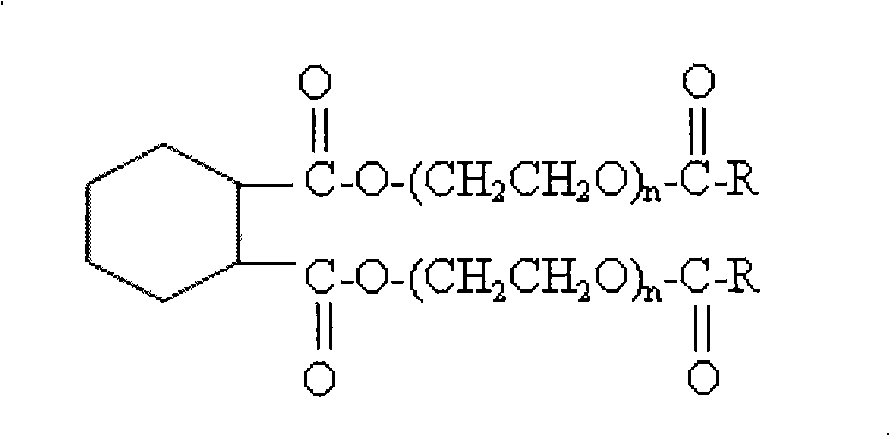

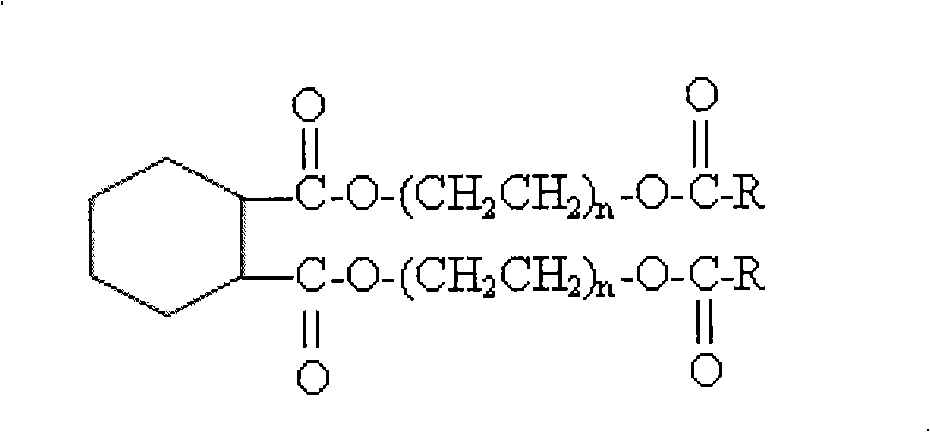

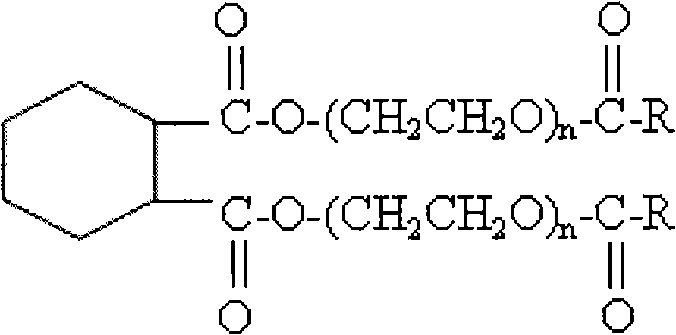

Hexa-hydrogen phthalate compound and preparation thereof

A technology of phthalate and phthalate alcohol, which is applied in the field of hexahydrophthalate compound and its preparation, can solve the problem of small molecular weight, plasticization efficiency containing benzene ring, healthy human body hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the hexahydrophthalate compound of the present invention comprises the first stage of esterification reaction, the second stage of esterification reaction, neutralization and washing steps, distillation steps, drying and water removal steps and filtration and purification steps:

[0025] The first stage of esterification reaction:

[0026] In order to obtain an excellent plasticizer effect, when carrying out the first stage of esterification reaction, use C 4 ~C 12 Dibasic alcohol and hexahydrophthalic anhydride are used as raw materials, and in the presence of a catalyst, they are put into a reactor with stirring and a condenser for esterification; wherein, the molar excess of dibasic alcohol is 0.1% to 20%; The amount of catalyst added is 0.1wt% to 3.0wt% based on the total weight of the reactants, and the catalyst type can be acidic (such as p-toluenesulfonic acid, etc.) or organometallic (such as tetraisopropyl titanate, etc.), but Cataly...

Embodiment 1

[0049] The reaction raw materials are 0.5 mole of hexahydrophthalic anhydride, 1.15 mole of diethylene glycol, 1.0 g of catalyst TIPT (tetraisopropyl titanate) and 34.0 g of xylene are simultaneously fed into the attached magnet for stirring and condensation In the four-necked flask of the reactor, the reaction temperature is 160°C to 180°C, and the reaction time is 5 hours. During the reaction, moisture must be removed. After the reaction is below the acid value of 3mgKOH / g, 0.96 moles of 2-ethylhexanoic acid (2 -EHA), the reaction temperature is 160°C-230°C, the reaction time is 5 hours, and the esterification reaction is completed after the acid value is below 5mgKOH / g. After the reaction is completed, the reaction liquid is neutralized with an aqueous solution of alkali metal hydroxide, and then washed with water, distilled, dried to remove water, and purified by filtration to obtain a hexahydrophthalate compound with a good hue.

[0050] Use the obtained hexahydrophthalat...

Embodiment 2

[0053] The reaction raw materials are 0.5 mole of hexahydrophthalic anhydride, 1.05 mole of triethylene glycol, 1.0 g of catalyst TIPT (tetraisopropyl titanate) and 34.0 g of xylene are simultaneously fed into the attached magnet for stirring and condensation In the four-necked flask of the reactor, the reaction temperature is 160°C to 180°C, and the reaction time is 5 hours. During the reaction, moisture must be removed, and 0.97 moles of 2-ethylhexanoic acid (2-ethylhexanoic acid (2- EHA), the reaction temperature is 160°C-230°C, the reaction time is 5 hours, and the esterification reaction is completed after the acid value is below 5mgKOH / g. After the reaction is completed, the reaction solution is neutralized with an aqueous solution of alkali metal hydroxide, and then washed with water, distilled, dried to remove water, and purified by filtration to obtain a hexahydrophthalate compound with good color.

[0054] Use the obtained hexahydrophthalate compound as the plasticiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com