Epoxy resin encapsulation adhesive and use thereof

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., and can solve problems such as large internal stress, yellow epoxy resin, and poor light transmission performance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Component A: 14.4 grams of bisphenol A type epoxy resin.

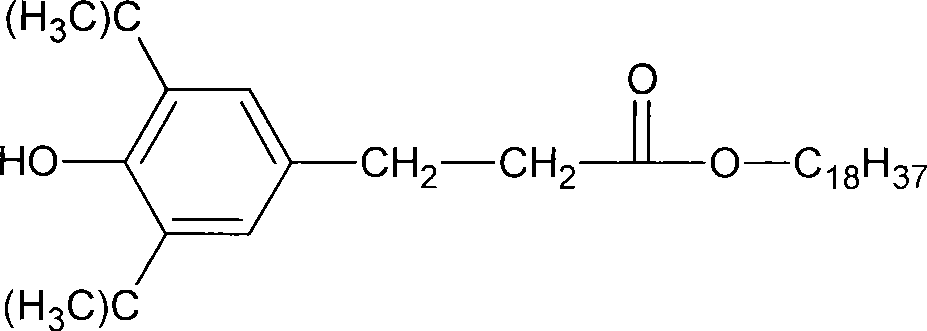

[0026] Preparation of component B: add an appropriate amount (for example, 0.115 grams) of a composite accelerator composed of ethyl triphenylphosphorus iodide and 0.022 grams of triphenylphosphorus into 14 grams of methyl hexahydrophthalic anhydride curing agent, and then add 0.302 grams of β -(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate antioxidant. Mix and stir in a 60°C oil bath for 30 minutes.

[0027] Mix components A and B at a mass ratio of 1:1, stir evenly, and defoam at 50°C in a vacuum oven with a vacuum degree not greater than 10 mm Hg.

[0028] Infusion method: Preheat the PTFE mold in an oven at 130°C for 1 hour, spray a small amount of release agent, pour in the encapsulation glue, then place it in an oven at 130°C, keep it warm for 50 minutes, and take it out naturally. Cool to room temperature.

Embodiment 2

[0030] Preparation of component A: 72.6 grams of bisphenol A type epoxy resin.

[0031] Preparation of component B: Add appropriate amount (eg 0.7 gram) of ethyl triphenylphosphorus iodide and 0.14 gram of triphenylphosphorus accelerator to 70 grams of methyl hexahydrophthalic anhydride curing agent, then add 1.71 grams of β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate. Mix and stir in a 60°C oil bath for 30 minutes.

[0032] Mix components A and B at a mass ratio of 1:1, stir evenly, and defoam at 50°C in a vacuum oven with a vacuum degree not greater than 10 mm Hg.

[0033] Infusion method: Preheat the PTFE mold in an oven at 130°C for 1 hour, spray a small amount of release agent, pour in the encapsulation glue, then place it in an oven at 130°C, keep it warm for 50 minutes, and take it out naturally. Cool to room temperature.

Embodiment 3

[0035] Preparation of component A: 364.2 grams of bisphenol A type epoxy resin.

[0036] The preparation of component B: Add appropriate amount (such as 4.2 grams) ethyl triphenyl phosphorus iodide and 0.7 gram triphenyl phosphorus accelerator in 350 grams of methyl hexahydrophthalic anhydride curing agent, then add 9.3 grams of β-(3 , 5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate antioxidant. Mix and stir in a 60°C oil bath for 30 minutes.

[0037] Mix components A and B at a mass ratio of 1:1, stir evenly, and defoam at 50°C in a vacuum oven with a vacuum degree not greater than 10 mm Hg.

[0038] Infusion method: Preheat the PTFE mold in an oven at 130°C for 1 hour, spray a small amount of release agent, pour in the encapsulation glue, then place it in an oven at 130°C, keep it warm for 50 minutes, and take it out naturally. Cool to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com