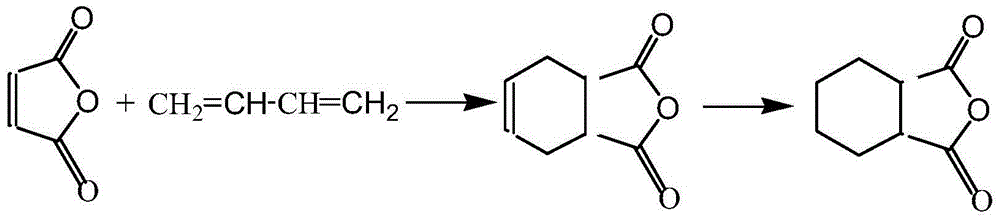

Hydrogenation catalyst, its preparation method and its application in preparation of hexahydrophthalic anhydride

A technology of hydrogenation catalyst and hexahydrophthalic anhydride, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Thoroughness and other issues, to achieve the effect of increased yield of the target product, low catalyst cost, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

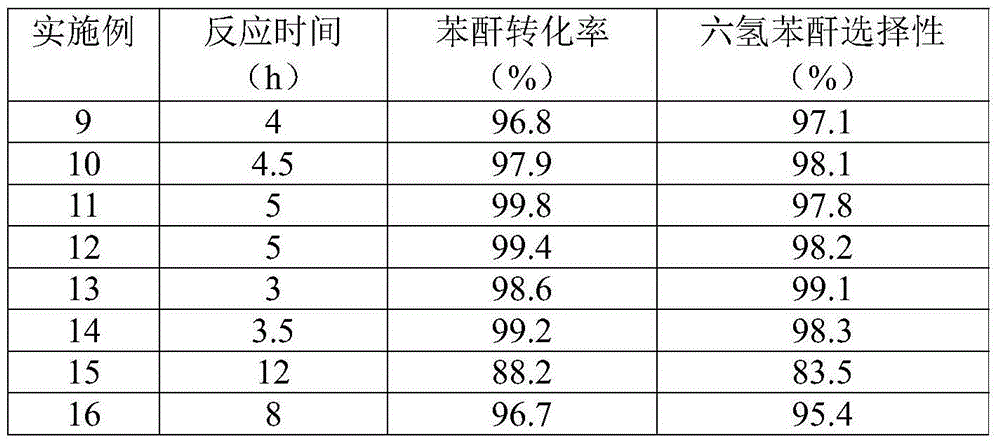

Examples

Embodiment 1

[0029] Preparation of carrier mesoporous carbon: Take 10g of commercial activated carbon, add 2g KOH, stir evenly, in the tube furnace, in the presence of nitrogen, treat at 900°C for 3h, naturally cool down to room temperature in the presence of nitrogen, take it out, and wash it repeatedly with deionized water , filter until the pH of the filtrate is equal to 9, and dry the solid at 120°C for later use. The specific surface area of the obtained mesoporous carbon is 500-600m 2 / g, the average pore diameter is 17-20nm.

Embodiment 2

[0031] Preparation of carrier mesoporous carbon: Take 10g of commercial activated carbon, add 4g Na 2 CO 3 , stir evenly, in a tube furnace, in the presence of nitrogen, treat at 800°C for 5 hours, naturally cool down to room temperature in the presence of nitrogen, take it out, repeatedly wash with deionized water, filter until the pH of the filtrate is equal to 8, and dry the solid at 120°C for later use , the specific surface area of mesoporous carbon is 800-900m 2 / g, the average pore diameter is 12-15nm.

Embodiment 3

[0033] Catalyst preparation: get mesoporous carbon 5g prepared in embodiment 1, add 50mg containing ruthenium (referring to Ru 3+ ) of ruthenium trichloride aqueous solution 10ml, stirred at room temperature for 2 hours, dried and treated at 300°C for 5 hours in the presence of nitrogen, and then reduced at 300°C for 3 hours in a hydrogen atmosphere to obtain a hydrogenation catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com