Epoxy resin glue for photoelectron attenuation-resistant packaging

An epoxy resin glue, epoxy resin technology, applied in circuits, electrical components, semiconductor devices and other directions, can solve the problems of reducing the reliability of high-power LEDs, easy to crack, easy to turn yellow, etc., to achieve excellent anti-aging characteristics, on-site Easy to formulate, excellent anti-decay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

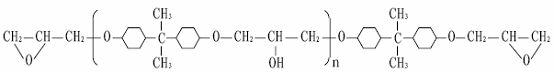

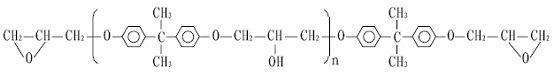

Image

Examples

Embodiment 1

[0032] Glue A (resin part), 10 parts of hydrogenated bisphenol A epoxy resin, 20 parts of alicyclic epoxy resin, 70 parts of bisphenol A type epoxy resin, 0.2 part of light stabilizer, 0.1 part of antioxidant and defoamer 0.1 copies;

[0033] B glue (curing agent part), 100 parts of methyl hexahydrophthalic anhydride, 1 part of organic phosphine compound and 2.5 parts of quaternary ammonium salt.

Embodiment 2

[0035] Glue A (resin part), 70 parts of hydrogenated bisphenol A epoxy resin, 30 parts of cycloaliphatic epoxy resin, 1.2 parts of light stabilizer, 1.5 parts of antioxidant and 2 parts of defoamer;

[0036] B glue (curing agent part), 40 parts of methyl hexahydrophthalic anhydride, 60 parts of hexahydrophthalic anhydride, 5 parts of organic phosphine compound.

Embodiment 3

[0038] Glue A (resin part), 40 parts of hydrogenated bisphenol A epoxy resin, 40 parts of alicyclic epoxy resin, 20 parts of bisphenol A type epoxy resin, 1.2 parts of light stabilizer, 1.5 parts of antioxidant and defoamer 2 copies;

[0039] B glue (cured part), 60 parts of methyl hexahydrophthalic anhydride, 40 parts of hexahydrophthalic anhydride, 2 parts of organic phosphine compound and 3 parts of cyclic amidine complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com