Internal combustion engine silencer

a technology of internal combustion engine and silencer, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., to achieve the effect of greater attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

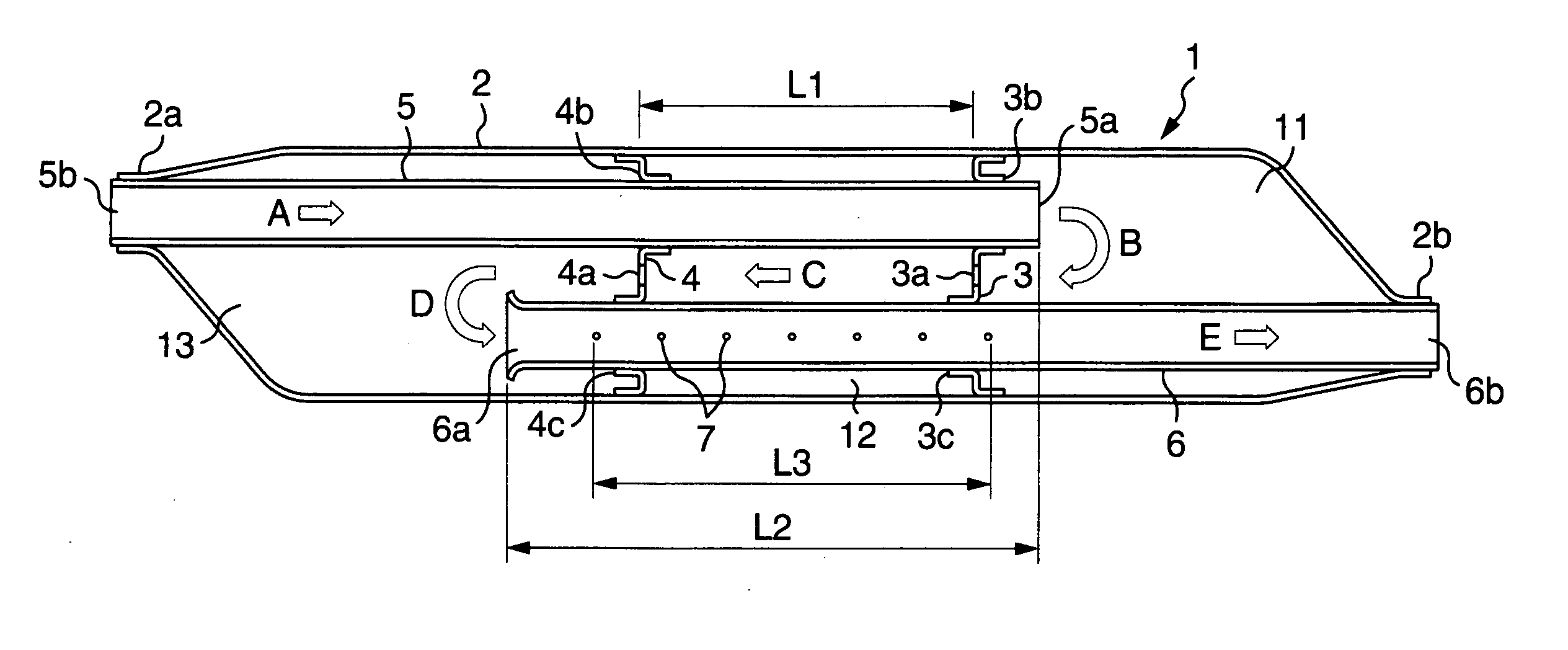

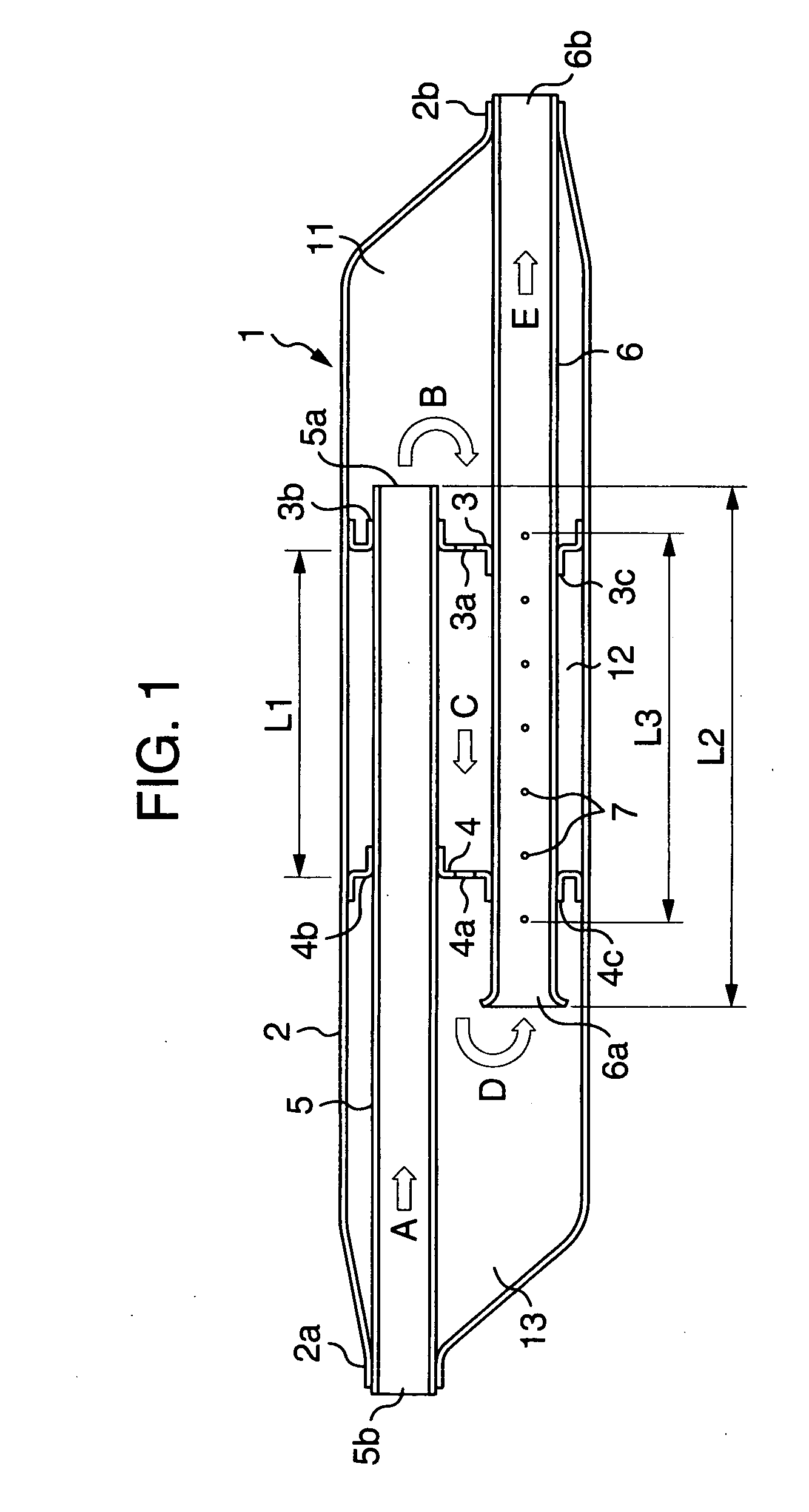

[0031]FIG. 1 and FIG. 4 show the invention.

[0032] In FIG. 1, a housing 2 in a muffler 1 is constituted of a metallic cylinder of which both ends are reduced in diameter to form constrictions 2a and 2b.

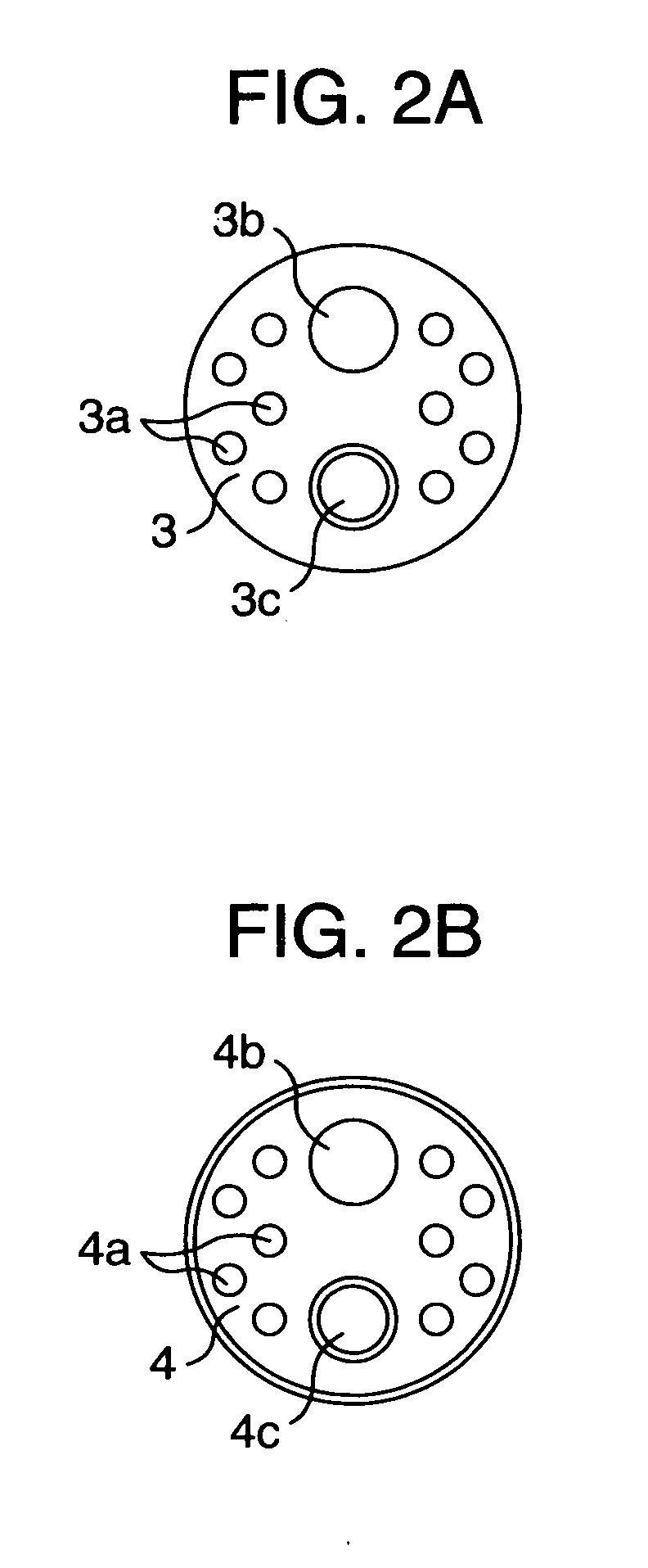

[0033] In the housing 2, a separator 3 in which a plurality of through holes 3a and two burring holes 3b and 3c are bored as shown in FIG. 2A and a separator 4 in which a plurality of through holes 4a and two burring holes 4b and 4c are bored as shown in FIG. 2B are fixed with a prescribed spacing L1 between them, and they partition the housing 2 in the lengthwise direction into a first expanding chamber 11, a second expanding chamber 12 and a third expanding chamber 13.

[0034] In the housing 2, forcing into its constriction 2a and the burring holes 3b and 4b of the separators 3 and 4, an inlet pipe 5 for introducing exhaust gas into the muffler 1 is disposed, and its downstream side aperture 5a opens into the first expanding chamber 11. Incidentally, an upstream side aperture 5b is c...

second embodiment

[0047]FIG. 5 and FIG. 6 show the invention.

[0048] Referring to FIG. 5, the housing of a muffler 21 is composed of a shell 22 cylindrically formed of a steel plate and outer plates 23 and 24 caulk-coupled to both ends of the shell 22. Within the housing, a separator 31 in which a plurality of through holes 31a and a burring hole 31b are bored as shown in FIG. 6 is fixed, and the housing is partitioned by the separator 31 into a first expanding chamber 29 and a second expanding chamber 30.

[0049] An inlet pipe 25, positioned on the first expanding chamber 29 side, is inserted into a burring hole 22a of the shell 22, with its end being blocked by a cap 27 disposed in the opposite position to the burring hole 22a.

[0050] Further, in the side face of the inlet pipe 25 are bored discharge ports (apertures) 28 so that exhaust gas in the inlet pipe 25 can flow into the first expanding chamber 29 via the discharge ports 28.

[0051] An outlet pipe 26 is inserted into a burring hole 24a of an o...

third embodiment

[0058]FIG. 7 shows the invention.

[0059] Referring to FIG. 7, the housing 42 of a muffler 41 is constituted of a metallic cylinder of which both ends are coaxially reduced in diameter to form a constriction 42a and a constriction 42b.

[0060] In the housing 42, the separator 3 in which through holes 3a are bored as shown in the first embodiment and the separator 4 in which the through holes 4a are bored are fixed with the prescribed spacing L1 between them, and they partition the housing 42 in the longitudinal direction into a first expanding chamber 51, a second expanding chamber 52 and a third expanding chamber 53.

[0061] In the housing 42, as in the foregoing embodiment, an inlet pipe 45 for introducing exhaust gas into the muffler 41 is disposed, held by the constriction 42a and the separators 3 and 4, and an aperture 45a on its downstream side opens into the first expanding chamber 51. Incidentally, an aperture 45b on its upstream side is connected to an upstream exhaust pipe.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com