MXene-based flexible polyvinyl alcohol electromagnetic shielding composite film and preparation method thereof

A polyvinyl alcohol, electromagnetic shielding technology, applied in the field of electromagnetic shielding materials, can solve the problem of shielding that has not been publicly reported, and achieve the effects of good electromagnetic shielding performance, excellent flexibility, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

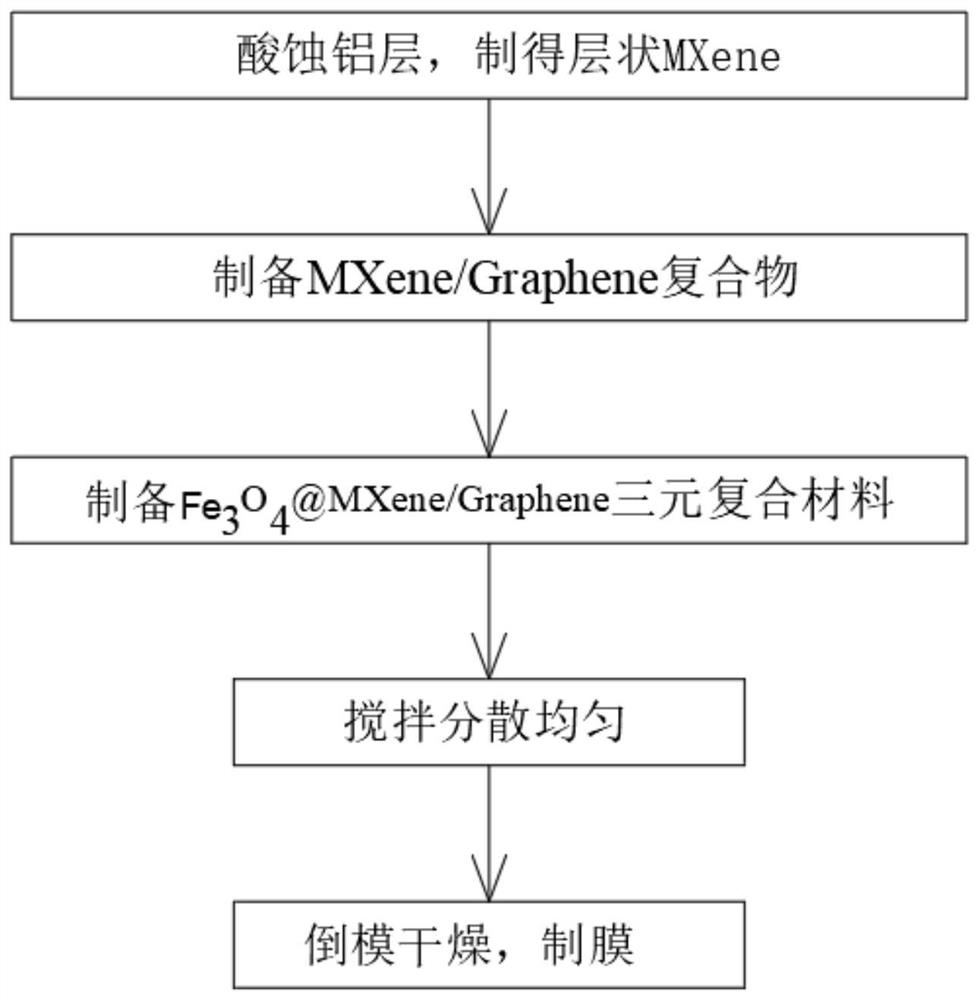

[0030] see figure 1 , a preparation method of MXene-based flexible polyvinyl alcohol electromagnetic shielding composite film, comprising the following steps:

[0031] Step 1: Etching away the aluminum layer in the MAX phase with hydrofluoric acid, filtering, washing and drying to obtain layered MXene;

[0032] Step 2, the MXene obtained in the step 1 and Graphene are mixed at a high speed by a ball mill at a mass ratio of 5:1 to obtain the MXene / Graphene compound of MXene and Graphene intercalation;

[0033] Step 3, the MXene / Graphene compound of step 2 gained and nanoparticle Fe 3 o 4 Disperse in deionized water at a mass ratio of 2:1, ultrasonicate the mixed solution, filter, wash and dry to obtain Fe 3 o 4 @MXene / Graphene Ternary Composites;

[0034] Step 4, the Fe obtained in step 3 3 o 4 @MXene / Graphene ternary compound and polyvinyl alcohol are dispersed in deionized water, and the mixed solution is stirred until the filler is evenly dispersed in the aqueous poly...

Embodiment 2

[0045] The basis for combining Example 1 is different in that,

[0046] (1) Add 2g of Ti 3 AlC 2 Add to 20mL of 49% hydrofluoric acid solution and stir at room temperature for 24h to etch away Ti 3 AlC 2 The aluminum layer in, obtained layered MXene through filtering, washing and drying;

[0047] (2) Gained MXene is mixed with Graphene at a mass ratio of 5:1, and mixed for 2h at a speed of 300r / min in a ball mill to obtain an MXene / Graphene compound of MXene and Graphene intercalation;

[0048] (3) Combine MXene / Graphene composite with nanoparticle Fe 3 o 4 Disperse in deionized water at a mass ratio of 2:1, ultrasonicate at 80°C for 2 hours, filter, wash and dry to obtain Fe 3 o 4 @MXene / Graphene Ternary Composites;

[0049] (4) Add 2g of Fe 3 o 4 @MXene / Graphene ternary compound and 18g of polyvinyl alcohol are dispersed in 180g of deionized water, stirred at 100r / min at 75°C for 2 hours until the polyvinyl alcohol is completely dissolved and the filler is evenly d...

Embodiment 3

[0052] Based on the basis of embodiment 1-2 but different in that,

[0053] (1) Add 2g of Ti 3 AlC 2 Add to 20mL of 49% hydrofluoric acid solution and stir at room temperature for 24h to etch away Ti 3 AlC 2 The aluminum layer in, obtained layered MXene through filtering, washing and drying;

[0054] (2) Gained MXene is mixed with Graphene at a mass ratio of 5:1, and mixed for 2h at a speed of 300r / min in a ball mill to obtain an MXene / Graphene compound of MXene and Graphene intercalation;

[0055] (3) Combine MXene / Graphene composite with nanoparticle Fe 3 o 4 Disperse in deionized water at a mass ratio of 2:1, ultrasonicate at 80°C for 2 hours, filter, wash and dry to obtain Fe 3 o 4 @MXene / Graphene Ternary Composites;

[0056] (4) 4g of Fe 3 o 4 @MXene / Graphene ternary compound and 16g of polyvinyl alcohol are dispersed in 180g of deionized water, stirred at 100r / min at 75°C for 2 hours until the polyvinyl alcohol is completely dissolved and the filler is evenly d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

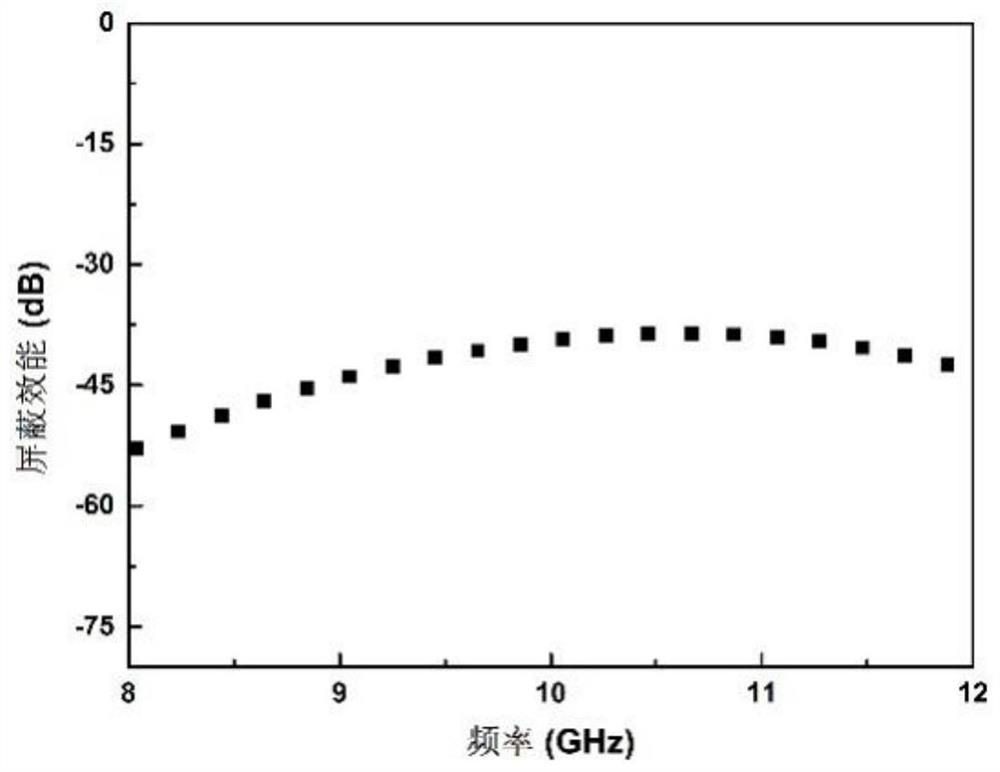

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com