Epoxy resin matrix nano-zinc oxide composite material and preparation method thereof

A nano-zinc oxide and epoxy resin technology, applied in the field of polymer-based nanocomposite materials, can solve the problems of poor crack resistance, reduced electrical performance, and high brittleness of pure epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

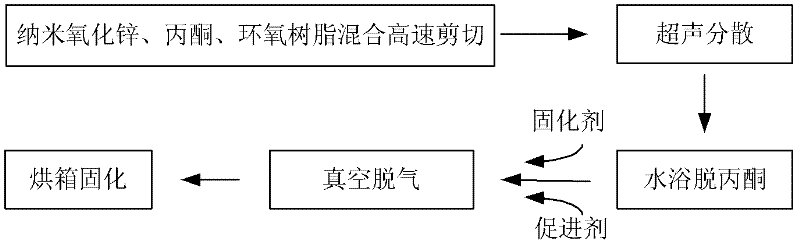

[0027] Such as figure 1 Shown, the preparation method of this epoxy resin-based nano-zinc oxide composite material comprises the following steps:

[0028] Step 1: Nano-zinc oxide, acetone, and epoxy resin are mixed with high-speed shearing. First, 0.5 parts by weight of nano-zinc oxide particles whose surface has been treated with KH560 are dried at 100 ° C for 6 hours, and then added to 40 parts by weight of ring In the mixed solution of epoxy resin diluent acetone and 100 parts by weight of epoxy resin, stir so that the dispersion is mixed without delamination, and then use a high-speed shear machine to process the dispersion for 15min at a speed of 5000r / min;

[0029] Step 2: Ultrasonic dispersion, use an ultrasonic generator to process the dispersion liquid after high-speed shearing treatment in step 1 with a power of 500W and a frequency of 20kHz for 15 minutes;

[0030] Step 3: Remove acetone in a water bath, put the dispersion treated by ultrasonic dispersion into a wa...

Embodiment 2

[0034] Such as figure 1 Shown, the preparation method of this epoxy resin-based nano-zinc oxide composite material comprises the following steps:

[0035] Step 1: Nano-zinc oxide, acetone, and epoxy resin are mixed with high-speed shearing. First, 9.5 parts by weight of nano-zinc oxide particles whose surface has been treated with KH550 are dried at 130 ° C for 8 hours, and then added to 60 parts by weight of ring In the mixed solution of epoxy resin diluent acetone and 100 parts by weight of epoxy resin, stir so that the dispersion is mixed without delamination, and then use a high-speed shear machine to process the dispersion for 40min with a rotating speed of 10000r / min;

[0036] Step 2: Ultrasonic dispersion, use the ultrasonic generator to process the dispersion liquid after the high-speed shearing treatment in step 1 with a power of 600W and a frequency of 24kHz for 30min;

[0037] Step 3: Remove acetone in a water bath, put the dispersion treated by ultrasonic dispersi...

Embodiment 3

[0041] Such as figure 1 Shown, the preparation method of this epoxy resin-based nano-zinc oxide composite material comprises the following steps:

[0042] Step 1: Nano-zinc oxide, acetone, and epoxy resin are mixed with high-speed shearing. First, 6 parts by weight of nano-zinc oxide particles whose surface has been mixed with KH570 and tetrabutyl titanate in any ratio are dried at 130°C for 10 hours. , then added to the mixed solution of 60 parts by weight of epoxy resin diluent acetone and 100 parts by weight of epoxy resin, stirred so that the dispersion was mixed without stratification, and then used a high-speed shearing machine to process the dispersion at a speed of 15000r / min Liquid 45min;

[0043] Step 2: Ultrasonic dispersion, the dispersion liquid after the high-speed shearing treatment in step 1 is treated with an ultrasonic generator at a power of 800W and a frequency of 22kHz for 45 minutes;

[0044]Step 3: Remove acetone in a water bath, put the dispersion tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com