Novel high quality LED packaging material

A technology of LED encapsulation and hybrid materials, applied in the direction of adhesive types, non-polymer adhesive additives, epoxy resin adhesives, etc., can solve the problems of damage to gold wires and solder joints, high prices, dead lights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

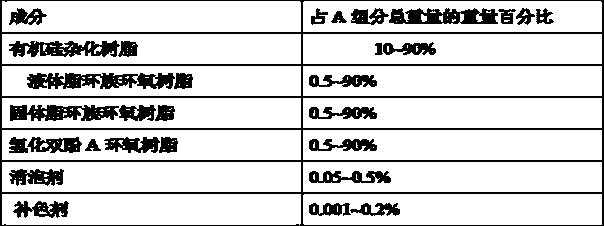

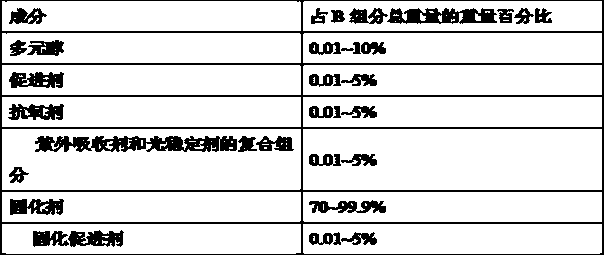

Method used

Image

Examples

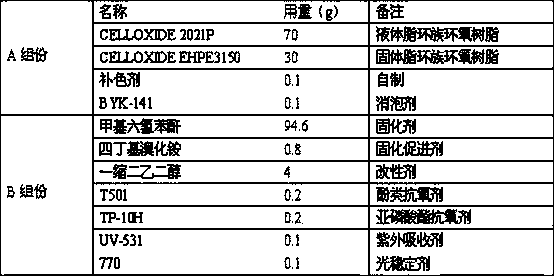

Embodiment 1

[0030]

[0031] Properties before curing

[0032]

[0033] Process conditions

[0034]

[0035] The components A and B are mixed and stirred according to the same weight ratio to cure evenly. The curing is carried out in stages. The short bake is cured at 135°C for 1 hour, and the long bake is cured at 150°C for 4 to 6 hours.

[0036] Properties after curing

[0037] project name condition unit Index value Refractive index Abbe ≥1.52 Transmittance 1mm % ≥96 glass transition temperature DSC ℃ ≥145 Linear expansion coefficient (1~100℃) TMA ppm / ℃ ≤75 Hardness (Shore D) 25 ℃ ≥85 water absorption 100℃/1h % ≤0.30 Kang sulfur pollution performance Sulfur fumigation at 80°C for 100 hours, light transmittance at 400nm wavelength % ≥85

Embodiment 2

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com