Quantum dots modified by macromolecular monomer, preparation method for quantum dots and application of quantum dots

A macromonomer and quantum dot technology, which is applied in the field of nano-fluorescent materials and preparation, and achieves the effects of good fluorescence stability, accurate and adjustable fluorescence performance, and high luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

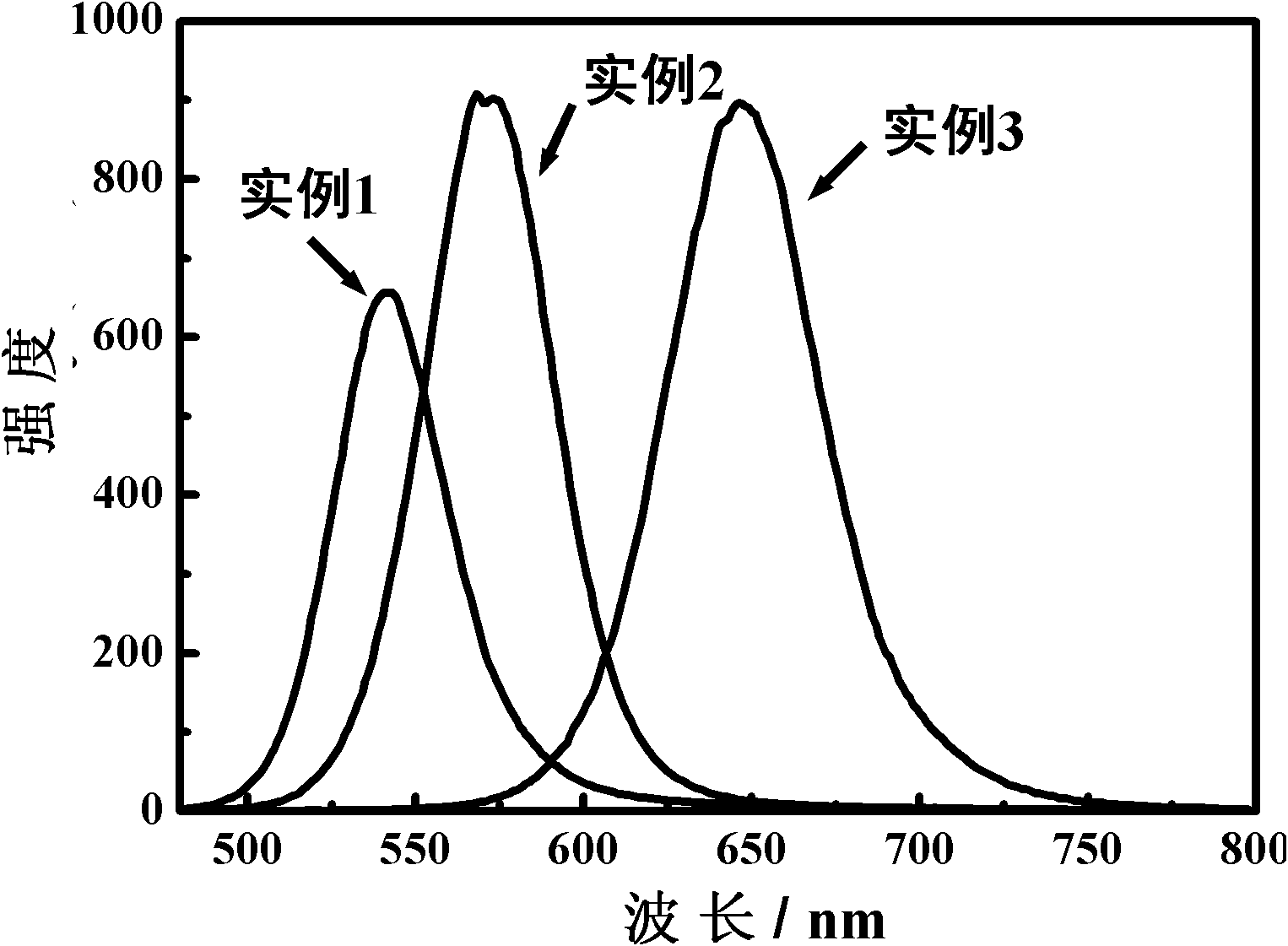

Embodiment 1

[0041] 1. Preparation of catalytic chain transfer agent CoBF

[0042] Add 3g of cobalt acetate and 2.5g of diacetyl to 250mL of diethyl ether pre-gassed with nitrogen for 2 hours to prepare a suspension, then add 15mL of boron trifluoride ether solution as a catalyst, and stir the reaction at room temperature to obtain a brown precipitate. The precipitate was filtered, washed with ice water, and dried at room temperature. The dried brown solid was recrystallized twice in methanol and dried to obtain CoBF as a brown powder.

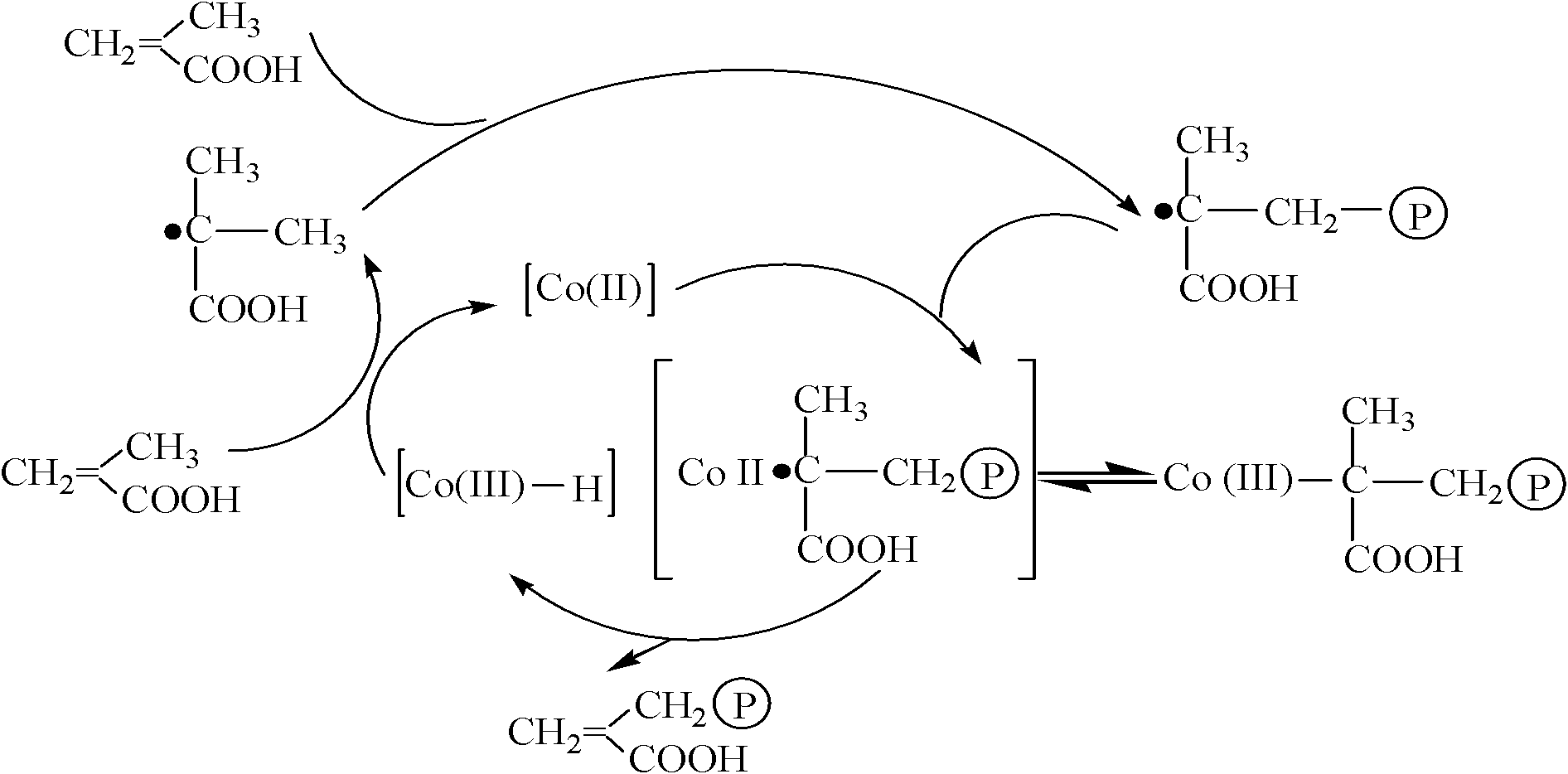

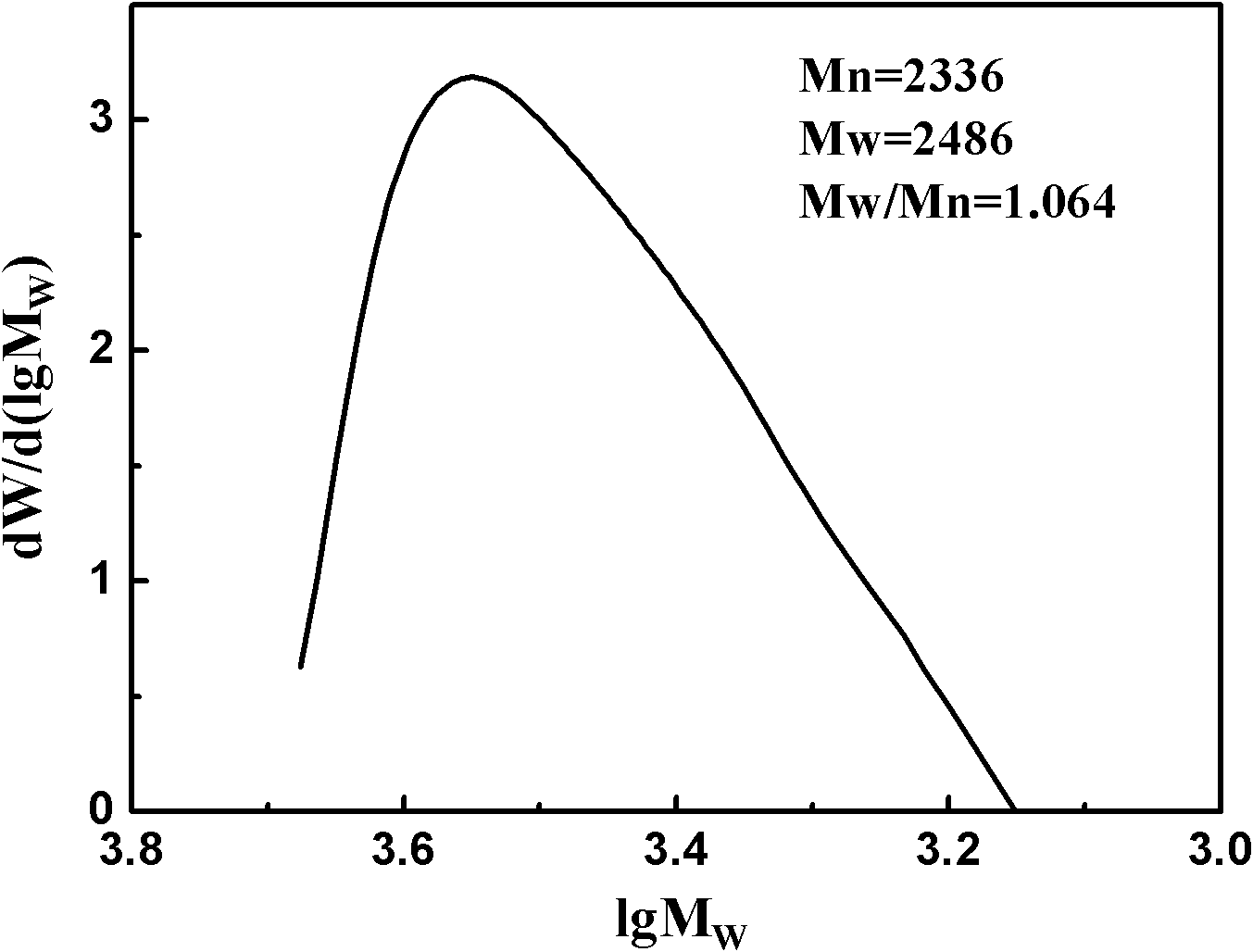

[0043] 2. Preparation of PMAA macromolecular ligands with double bonds at the end by catalytic chain transfer polymerization

[0044] Methacrylic acid and distilled water were pretreated to remove free oxygen from the solution. 0.3g of initiator VA-044 and 10mg of catalyst CoBF were dissolved in 2mL of acetone, then added to a three-necked flask filled with 150mL of distilled water, 5mg of catalyst was dissolved in 74g of MAA and placed in a constant pre...

Embodiment 2

[0050] 1. Preparation of catalytic chain transfer agent CoBF

[0051] The preparation process of the catalytic chain transfer agent CoBF in this example is the same as that in Example 2.

[0052] 2. Preparation of PMAA macromolecular ligands with double bonds at the end by catalytic chain transfer polymerization

[0053] Methacrylic acid and distilled water were pretreated to remove free oxygen from the solution. 0.4g of initiator VA-044 and 10mg of catalyst CoBF were dissolved in 2mL of acetone, then added to a three-necked flask filled with 150mL of distilled water, 5mg of catalyst was dissolved in 74g of MAA and placed in a constant pressure funnel, then vacuumed and passed into High-purity nitrogen, repeated six times to remove oxygen in the device, sealed. When the temperature of the water bath was constant at 55°C, the MAA monomer was added dropwise, and after the MAA was added dropwise, the reaction was carried out for 1 h. The reaction product was placed in a watch ...

Embodiment 3

[0059] 1. Preparation of catalytic chain transfer agent CoBF

[0060] The preparation process of the catalytic chain transfer agent CoBF in this example is the same as that in Example 2.

[0061] 2. Preparation of PMAA macromolecular ligands with double bonds at the end by catalytic chain transfer polymerization

[0062] Methacrylic acid and distilled water were pretreated to remove free oxygen from the solution. 0.3g of initiator VA-044 and 10mg of catalyst CoBF were dissolved in 2mL of acetone, then added to a three-necked flask filled with 150mL of distilled water, 5mg of catalyst was dissolved in 74g of MAA and placed in a constant pressure funnel, then vacuumed and passed into High-purity nitrogen, repeated six times to remove oxygen in the device, sealed. When the temperature of the water bath was constant at 65°C, the MAA monomer was added dropwise. After the MAA was added dropwise, the reaction was carried out for 1 h. The reaction product was placed in a watch glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com