Instant-dissolved cationic polyacrylamide capsulation agent and preparing method thereof

A technology of polyacrylamide and acrylamide, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of long time for complete dissolution, unstable mud performance, short dissolution time, etc., and achieve long-term storage and long-distance The effect of excellent transportation and coating inhibition performance and simple post-treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

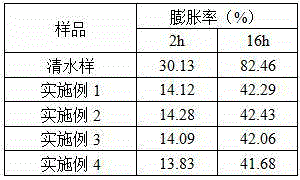

Examples

Embodiment 1

[0024] The first monomer acrylamide 27.00g, the second monomer acryloyloxyethyl dimethyl benzyl ammonium chloride 15.75g, the third monomer hydroxyethyl methacrylate 2.25g, sodium persulfate 0.09g and distilled water 45.00g, stir to make its aqueous solution completely dissolve; add emulsifier sorbitan monostearate 1.80g, kerosene 898.20g in the reactor, add above-mentioned aqueous solution after mixing and dissolving completely; Then dissolve 0.09g sodium bisulfite Put 10.00g of distilled water in a constant-pressure dropping funnel; pass in inert gas nitrogen and keep it for 30 minutes; then start to add aqueous sodium bisulfite solution dropwise, and complete the dropwise addition within 15-25 minutes; keep the nitrogen atmosphere at 45°C After stirring and reacting for 4 hours, add the polymerized emulsion dropwise to the ethanol solution, and at the same time stir at a high speed to precipitate the polymer. After suction filtration, the granular product is washed with acet...

Embodiment 2

[0027] The first monomer sodium acrylate 17.00g, the second monomer dimethyl diallyl ammonium chloride 2.60g, the third monomer hydroxyethyl methacrylate 0.40g, ammonium persulfate 0.001g and distilled water 160.00g, Stir to make the aqueous solution completely dissolve; add 16.00 g of emulsifier sorbitan trioleate and 784.00 g of white oil into the reactor, and add the above aqueous solution after mixing and dissolving completely; then dissolve 0.001 g of pentaerythritol in 20.00 g of distilled water and place In the constant pressure dropping funnel; pass inert gas nitrogen and keep it for 30 minutes; then start to drop pentaerythritol aqueous solution, and drop it within 15-25 minutes; keep the nitrogen atmosphere, stir and react at 60°C for 6 hours, and then polymerize The final emulsion is added dropwise to the ethanol solution, while stirring at a high speed to precipitate the polymer. After suction filtration, the granular product is washed with acetone several times, an...

Embodiment 3

[0030] The first monomer acrylamide 48.38g, the second monomer methacryloxyethyltrimethylammonium chloride 26.25g, the third monomer hydroxypropyl methacrylate 0.37g, potassium persulfate 0.075g and distilled water 160.00g, stir to make its aqueous solution completely dissolve; add emulsifier polyoxyethylene sorbitan monostearate 7.50g, cyclohexane 742.50g in the reactor, add above-mentioned aqueous solution after mixing and dissolving completely; Then add 0.075g Tetramethylethylenediamine was dissolved in 15.00g of distilled water, placed in a constant pressure dropping funnel; inert gas nitrogen was passed through, and kept for 30 minutes; then tetramethylethylenediamine aqueous solution was added dropwise, within 15-25 minutes After the addition is complete; maintain a nitrogen atmosphere, stir and react at 50°C for 4 hours, add the polymerized emulsion dropwise to the ethanol solution, and stir at a high speed at the same time to precipitate the polymer. After suction filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com