Preparation method of core-shell acrylic acid elastic emulsion containing phosphate group

A phosphate group, elastic emulsion technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of insufficient cross-linking of the coating film, poor water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

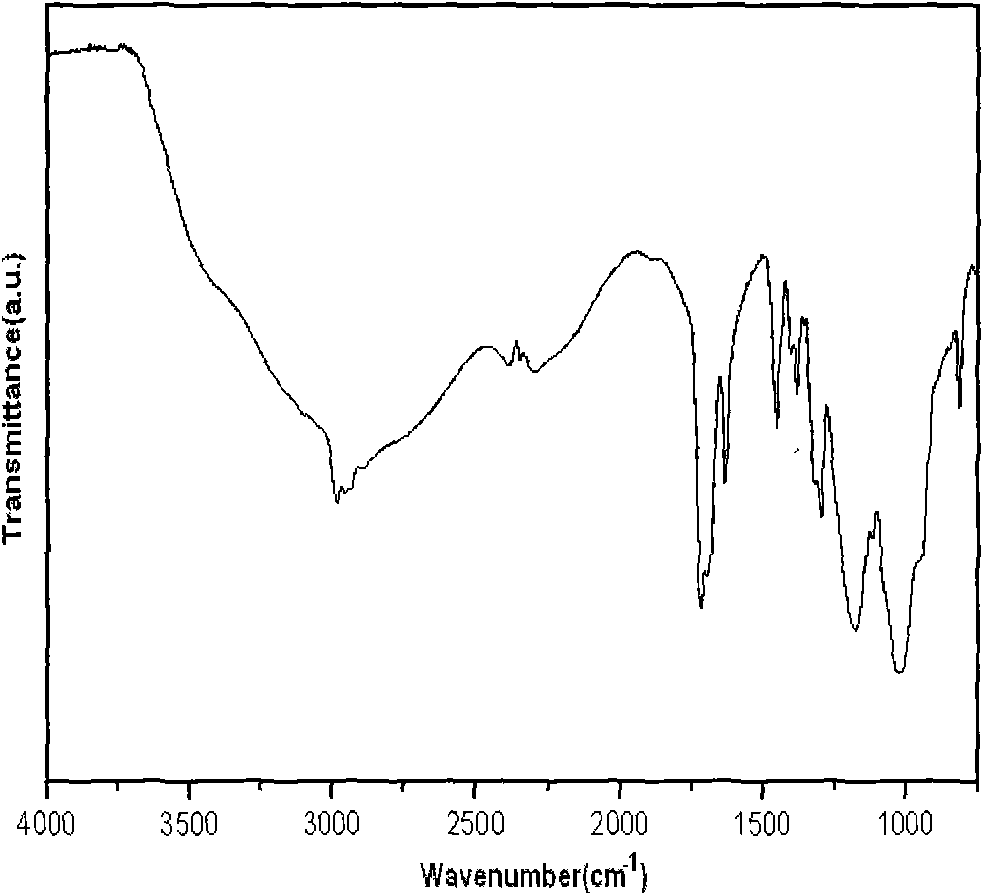

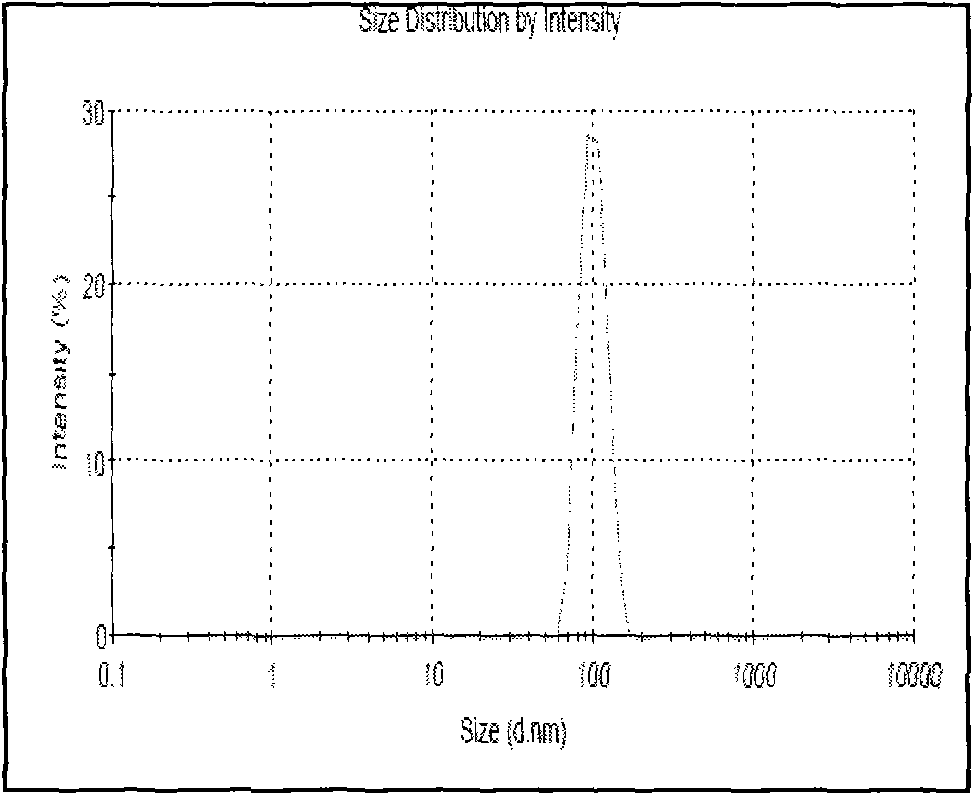

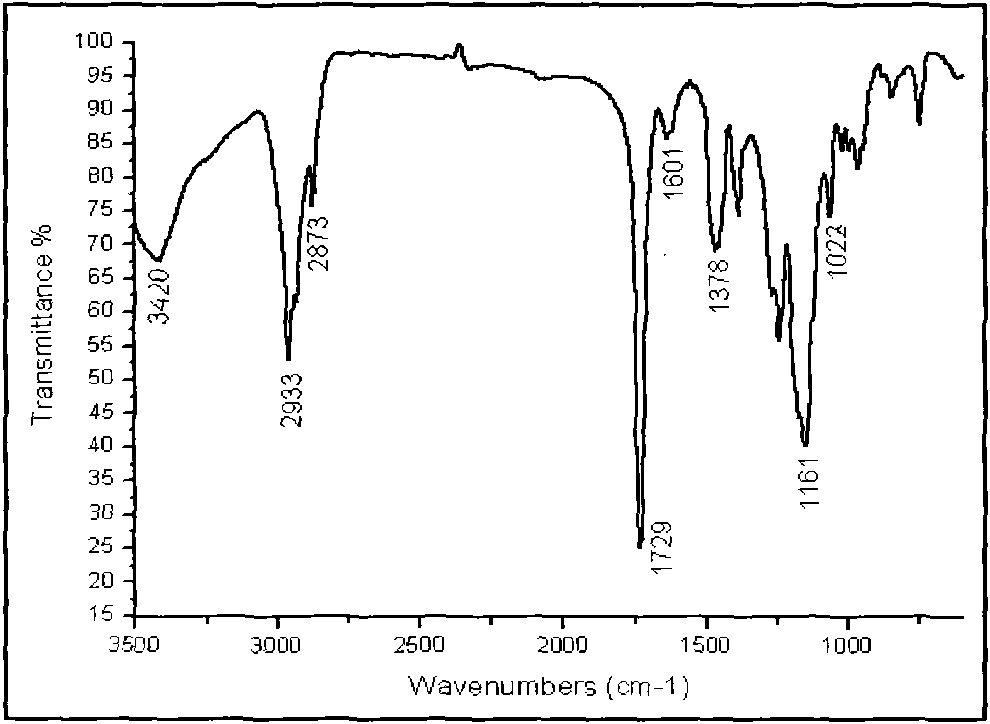

Image

Examples

Embodiment 1

[0023] The components of the emulsion and parts by weight thereof (in gram) are as follows:

[0024]

[0025] Specific steps:

[0026] (1) Preparation of Phosphate Ester Monomer

[0027] Put 33.8ml of hydroxypropyl methacrylate in a cold water bath, and add 17.7gP in batches under high-speed stirring 2 o 5 , quickly raised the temperature to 65°C, and finished the reaction for 3.5 hours, then added 1.8ml of water, raised the temperature to 85°C, and reacted for 1.5 hours to obtain a transparent phosphate monomer.

[0028] (2) Add 10 mL of deionized water to sodium lauryl sulfate and ammonium persulfate respectively to fully dissolve them;

[0029] (3) Add 2 / 3 of the emulsifier solution in (2), 1 / 3 of the initiator solution, OP-10, and 50 mL of deionized water into a four-neck flask equipped with a stirrer, start stirring and heat up. A mixed monomer of methyl methacrylate (10.0 g) and butyl methacrylate was prepared. Get 10% of the mixed monomers and add it into the t...

Embodiment 2

[0032] The components of the emulsion and parts by weight thereof (in gram) are as follows:

[0033]

[0034] Specific steps:

[0035] (1) Preparation of Phosphate Ester Monomer

[0036] Put 40.6ml of hydroxypropyl methacrylate in a cold water bath, and add 17.7gP in batches under high-speed stirring 2 o 5 , quickly raised the temperature to 75°C, and finished the reaction for 4.0 hours, then added 2.3ml of water, raised the temperature to 90°C, and reacted for 2.0 hours to obtain a transparent phosphate monomer.

[0037] (2) Add 10 mL of deionized water to sodium lauryl sulfate and ammonium persulfate respectively to fully dissolve them;

[0038] (3) Add 2 / 3 of the emulsifier solution in (2), 1 / 3 of the initiator solution, OP-10, and 50 mL of deionized water into a four-neck flask equipped with a stirrer, start stirring and heat up. A mixed monomer of methyl methacrylate (9.4 g) and butyl methacrylate was prepared. Get 20% of the mixed monomers and add it into the th...

Embodiment 3

[0041] The components of the emulsion and parts by weight thereof (in gram) are as follows:

[0042]

[0043] (1) Preparation of Phosphate Ester Monomer

[0044] Put 47.3ml of hydroxypropyl methacrylate in a cold water bath, and add 17.7gP in batches under high-speed stirring 2 o 5 , quickly raised the temperature to 85°C, and finished the reaction for 4.5 hours, then added 3.0ml of water, raised the temperature to 95°C, and reacted for 2.5 hours to obtain a transparent phosphate ester monomer.

[0045] (2) Add 10 mL of deionized water to sodium lauryl sulfate and ammonium persulfate respectively to fully dissolve them;

[0046] (3) Add 2 / 3 of the emulsifier solution in (2), 1 / 3 of the initiator solution, OP-10, and 50 mL of deionized water into a four-neck flask equipped with a stirrer, start stirring and heat up. A mixed monomer of methyl methacrylate (9.4 g) and butyl methacrylate was prepared. Get 30% of the mixed monomers and add it into the three-necked bottle. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com